Nuclide-containing heavy metal high-concentration acid separation system and separation method

A separation system and separation method technology are applied in the field of radiation wastewater treatment, which can solve the problems of low separation efficiency of acid and salt, inability to separate acid and salt, and high salt permeability, so as to facilitate automatic production, avoid direct contact, The effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

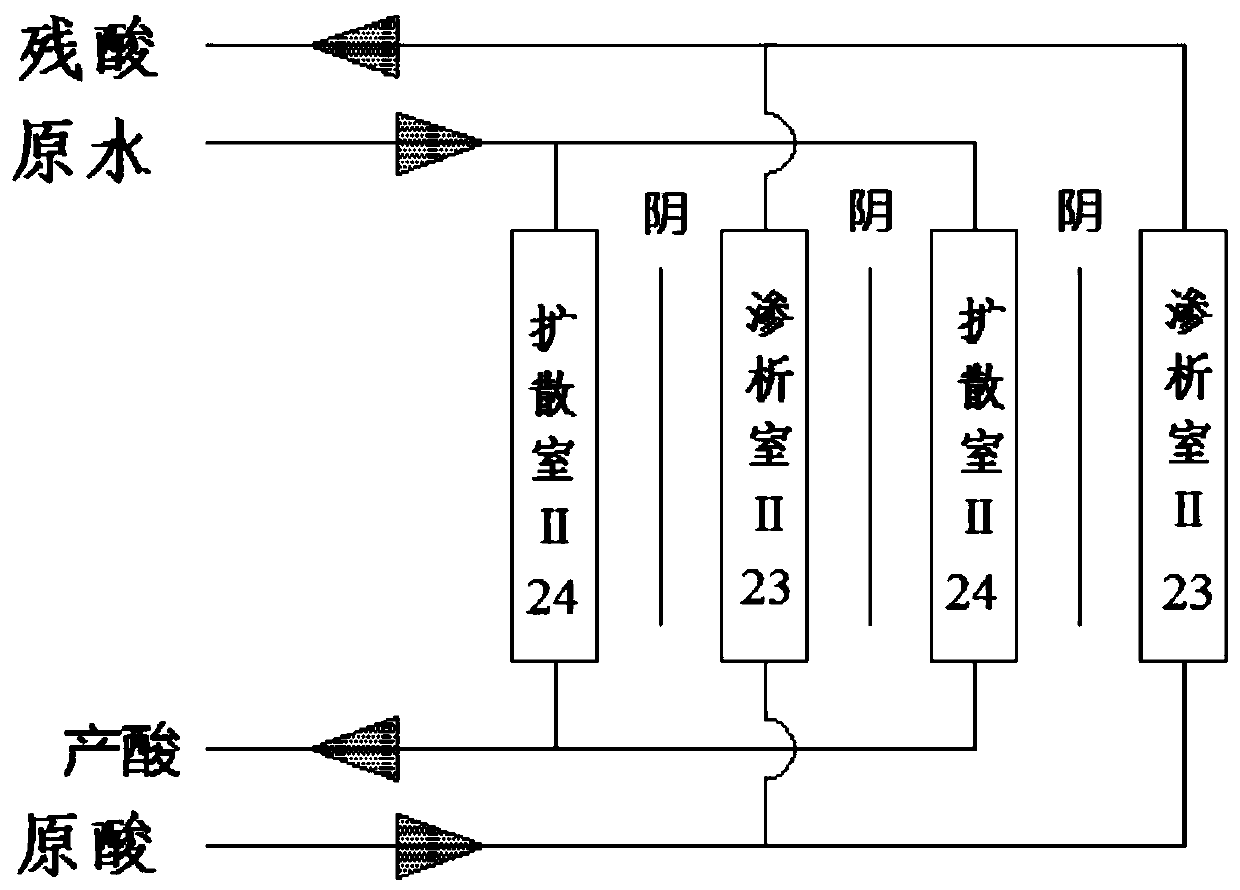

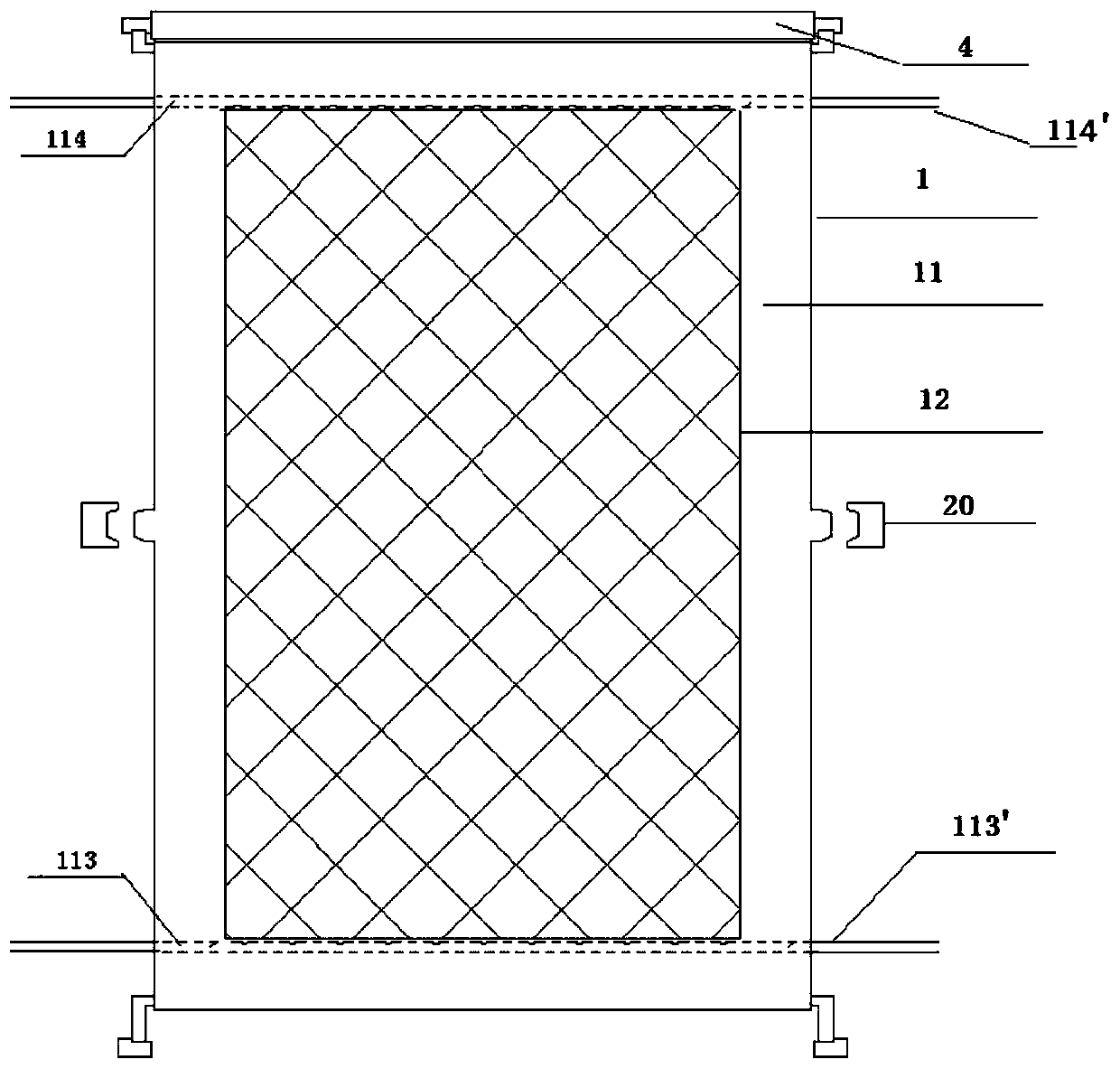

[0178] Take the automatic loading and unloading membrane stack of the present invention, take the continuous plate diffusion dialysis anion exchange membrane GN-JAM-DD120 (produced by Jinda Tech Electronics System (Beijing) Co., Ltd.), the surface width is 500mm, and the total membrane length is 200m; The partitions are GN-WNC-400×800 from Kindatec, with an effective membrane area of 0.266 square meters per sheet, a total of 8 sheets, with an area of 2.13m 2 ; The size of the membrane separator is 400mm×800mm, the thickness is 6mm, the thickness of the inner network is 5mm, and the number of membrane separators is 7. The processing flow refers to figure 1 shown. in, figure 1 In , "yin" refers to the anion exchange membrane.

[0179] The water source to be treated is the waste liquid produced by adding acid to dissolve the spent fuel in the reprocessing of spent fuel, in which the original acid is a high-acid and high-level radioactive waste liquid, and its composition is...

Embodiment 2

[0185] The method used in this embodiment is the same as in Example 1, the only difference being that the membrane used is a cation exchange membrane I, specifically the continuous plate diffusion dialysis cation exchange membrane GN-JCM-DD120 of Jinda Tech Electronics Systems (Beijing) Co., Ltd., and the same Therefore, the raw acid and raw water form a cross-flow on both sides of the membrane, and the obtained acid production and residual acid, as well as the recovery rate are shown in Table 2 below:

[0186] Table 2 only treats the result of raw acid with cation exchange membrane I

[0187]

[0188] Note: In Table 2, the "acid generation" and "residual acid" are obtained from the membrane stack formed by the separate cation exchange membrane I and the membrane separator.

Embodiment 3

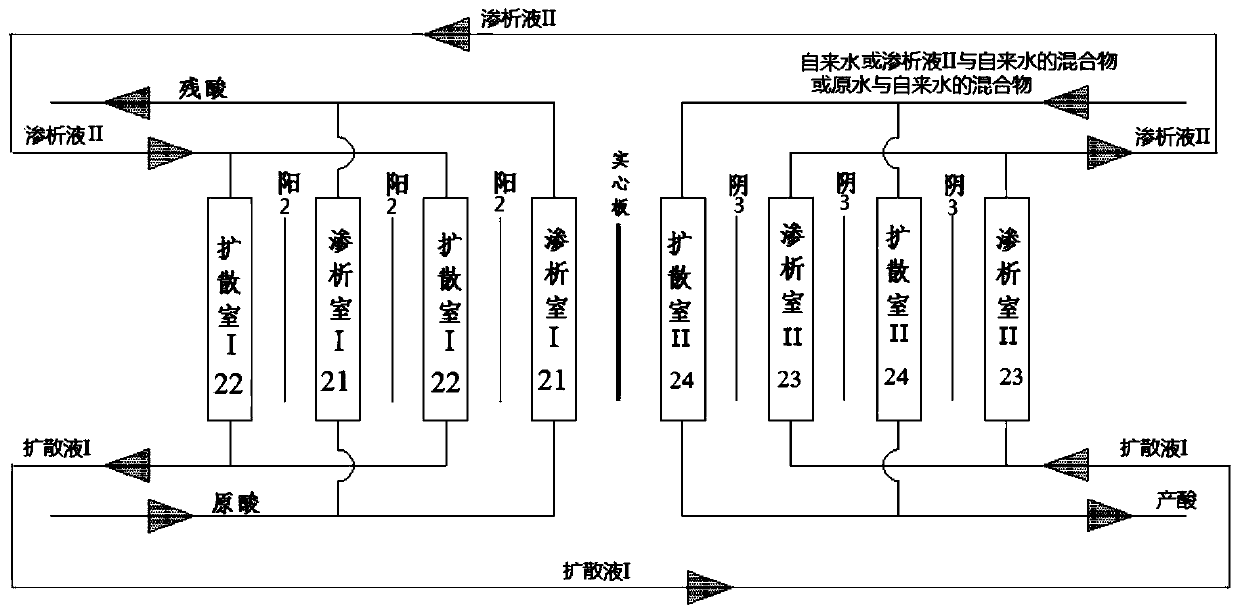

[0190] The source of raw materials used in this embodiment is the same as in Example 1, and the feed rate is the same. The difference is that the membrane stack composition adopted in this embodiment includes cation exchange membrane I and membrane separators to form the first membrane group and anion exchange membrane and membrane separator. The plates form the second membrane group, wherein the number ratio of the membrane separators in the first membrane group to the membrane separators in the second membrane group is 1:1; then press figure 2 as well as Figure 12 Shown in and out of the water operation, the results are shown in Table 3.

[0191] Table 3 Utilizes separation system of the present invention to separate and process raw acid result

[0192]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com