Plate cold and hot rapid circulation age forming method and device

An aging forming, rapid cycle technology, applied in forming tools, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of slow reduction of material elastic stress and long forming time, so as to reduce stress level, reduce aging forming time, promote The effect of uniform precipitation and dispersion distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

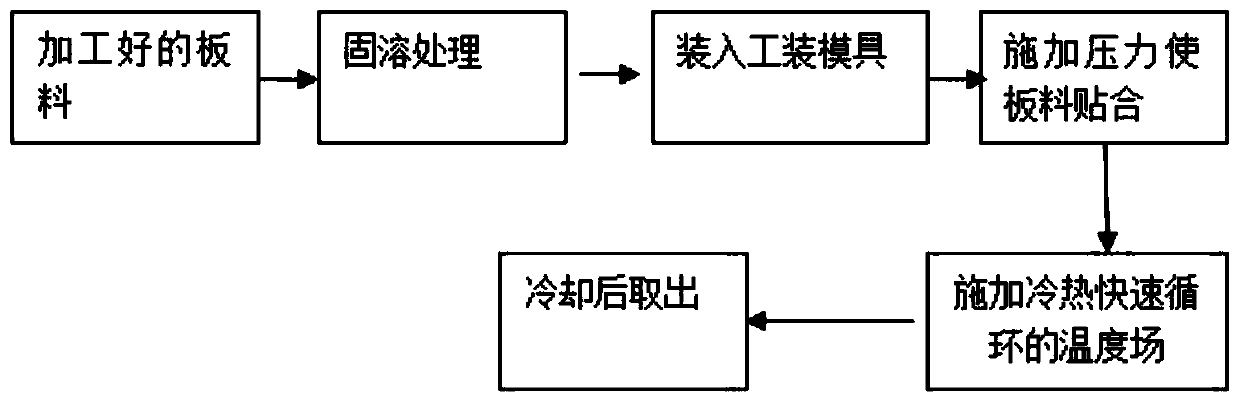

[0031] like Figure 1-3 As shown, the present embodiment provides a cold and hot rapid cycle aging forming method for sheet metal, which includes the following steps:

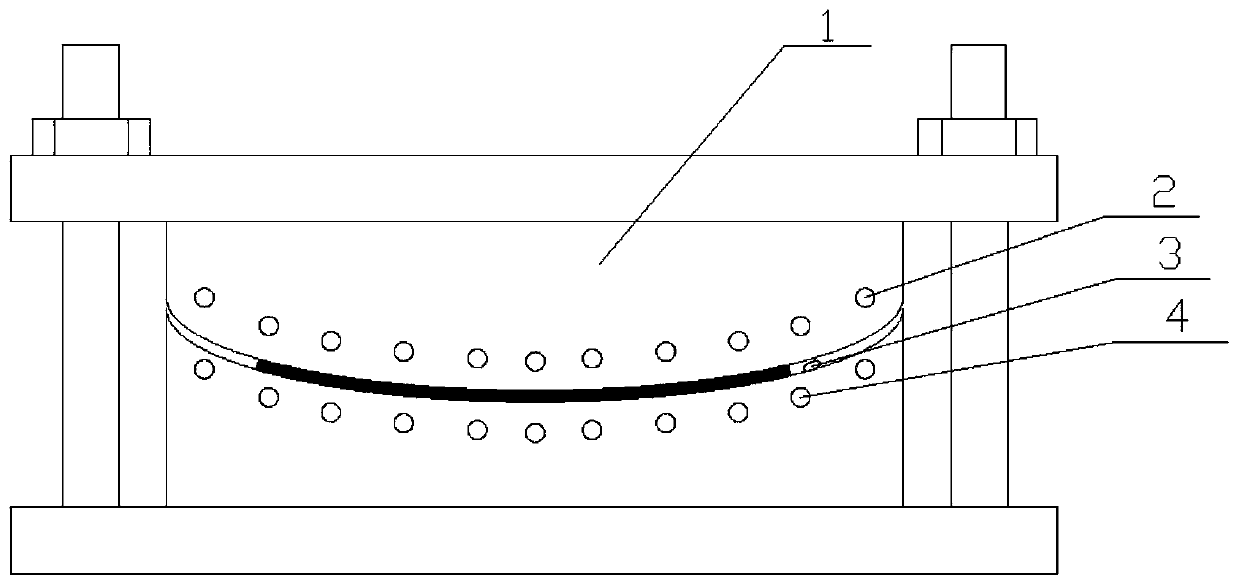

[0032] Step 1. Put the solid solution treated sheet into the die horizontally, and then press the punch on the sheet;

[0033] Step 2, put the forming die 1 into the pressure device to apply pressure, so that the sheet material is tightly attached to the profile surface of the forming die 1, tighten the pressure-holding nut, and maintain the pressure of the forming die 1 on the sheet material;

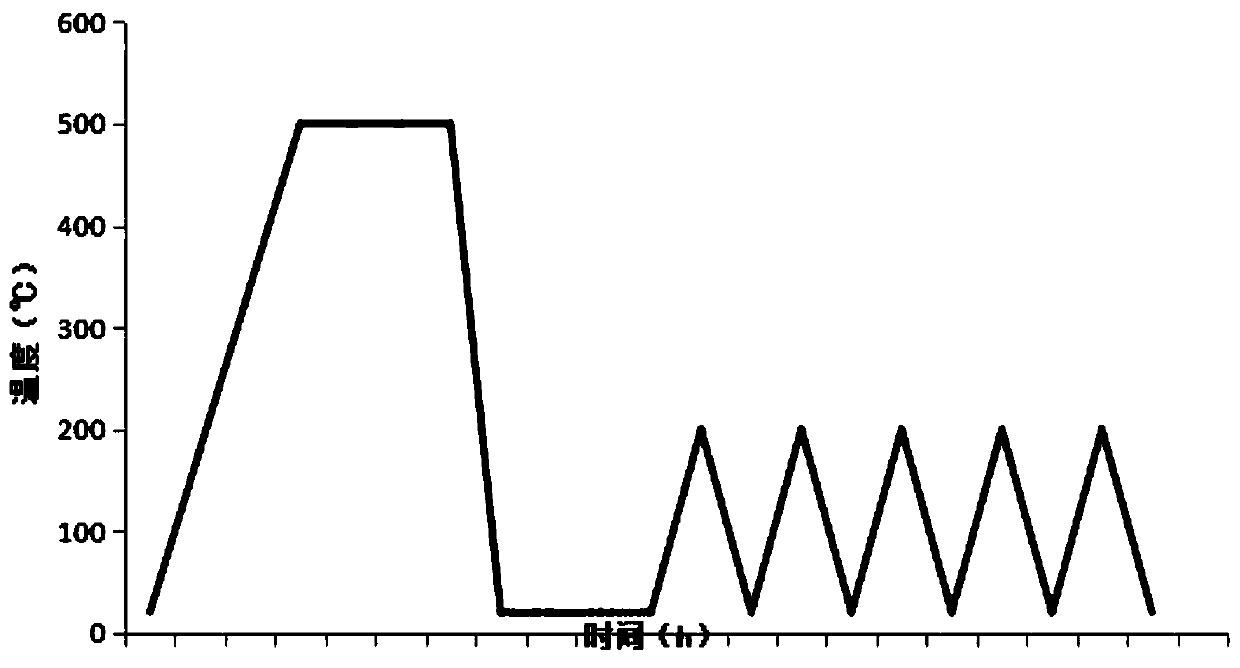

[0034] Step 3, start the temperature control system, and enter the cooling and heating cycle aging forming process: at this time, the forming mold 1 is at room temperature, and the heating device is activated, so that the forming mold 1 is heated to a temperature slightly higher than the aging temperature;

[0035] Step 4. After reaching the set temperature, the temperature control system will turn off the heating devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com