A kind of ferric oxide bismuth sulfide nanocomposite material and its preparation and application

A nano-composite material, ferric oxide technology, applied in wave energy or particle radiation treatment materials, drug combinations, X-ray contrast agent preparation, etc., can solve the lack of image information, poor cell compatibility, utilization efficiency of photothermal materials low problems, to achieve the effects of excellent photothermal conversion efficiency, easy preparation, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 0.32g of anhydrous FeCl 3 and 0.3 g PSSMA were dissolved in 20 mL of diethylene glycol, stirred at 60 °C for 30 min, and then 0.5 g CH 3 COONa was added to the mixture. After dissolving for 30 min, it was transferred to a 100 mL stainless steel reaction kettle lined with para-polyphenylene and sealed. The reaction kettle was placed in a high-temperature oven at 200°C for heat treatment for 7 hours, and after being naturally cooled to room temperature, the reaction mixture was centrifuged (8500 rpm, 5 min), and washed three times with distilled water and ethanol to obtain the product Fe 3 O 4 particles. The samples were finally vacuum dried for further use.

[0056] Dissolve 0.2 g of dopamine in 40 mL of Tris-HCl buffer solution (pH=8.5), then add 80 mg of Fe 3 O 4 particles. It was completely dispersed under the condition of ultrasound, placed on a shaker to react for 4 hours, the reaction mixture was centrifuged (8500 rpm, 5 min), and the product was washed thre...

Embodiment 2

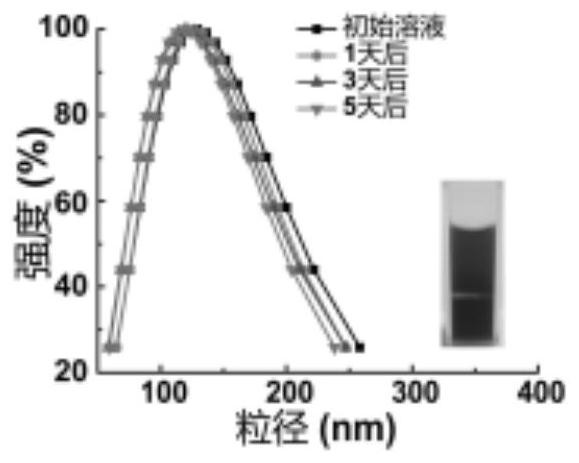

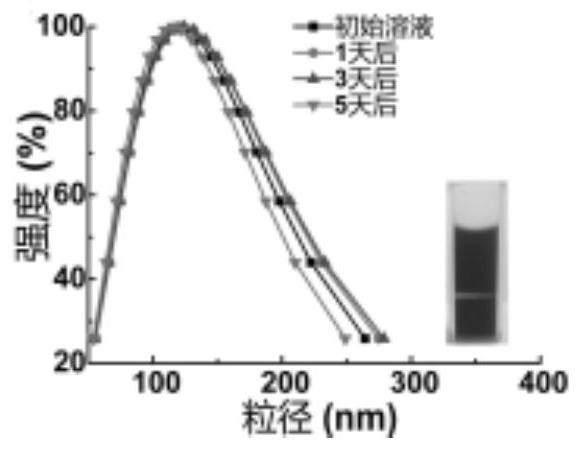

[0060] Take a little Fe prepared in Example 1 3 O 4 @PDA@BSA-Bi 2 S 3 Particles, dispersed in distilled water, PBS, 1640 medium, Figure 1a -c shows that the hydration kinetic diameter of the material does not change significantly after being placed for 5 days, and the Tyndall phenomenon is obvious in the three systems, all of which have good colloidal stability. The morphology and microstructure of the material were observed by TEM. After ultrasonically dispersing an appropriate amount of nanosheets uniformly in absolute ethanol, the copper mesh coated with carbon film was immersed in the above-mentioned absolute ethanol. After the samples were naturally dried, they were observed and photographed by TEM (the operating voltage of the TEM was 200 kV). Depend on Figure 2a , 2b It can be seen that the material obtained in Example 1 has an ultra-small nanoparticle structure.

Embodiment 3

[0062] Fe prepared in Example 1 was measured and calculated using TGA (TGA-50 thermogravimetric analyzer) 3 O 4 @PDA@BSA-Bi 2 S 3 The percentage content of each component in the particles, respectively taking a certain mass of Fe 3 O 4 , Fe 3 O 4 @PDA, BSA-Bi 2 S, Fe 3 O 4 @PDA@BSA-Bi 2 S 3 The particles were added to the platinum crucible of the thermogravimetric analyzer. After reading the mass of the added sample, the experimental parameters were set to perform the TGA test. The test condition was to increase from room temperature to 800°C at 15°C / min in an air atmosphere. Fe prepared in Example 1 was tested and analyzed using FTIR (NicoletNexus 670 infrared spectrometer) 3 O 4 @PDA@BSA-Bi 2 S 3 The composition and structure of , take a little Fe 3 O 4 @PDA, BSA-Bi 2 S 3 , Fe 3 O 4 @PDA@BSA-Bi 2 S 3 The particles were mixed with a certain amount of potassium bromide (KBr) powder, and ground under an infrared lamp to ensure the dryness of the sample. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com