Tubular solid oxide fuel cell structure

A solid oxide and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of poor battery mass transfer performance, temperature and thermal stress, and achieve the goals of avoiding temperature and thermal stress, reducing power consumption, and reducing flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

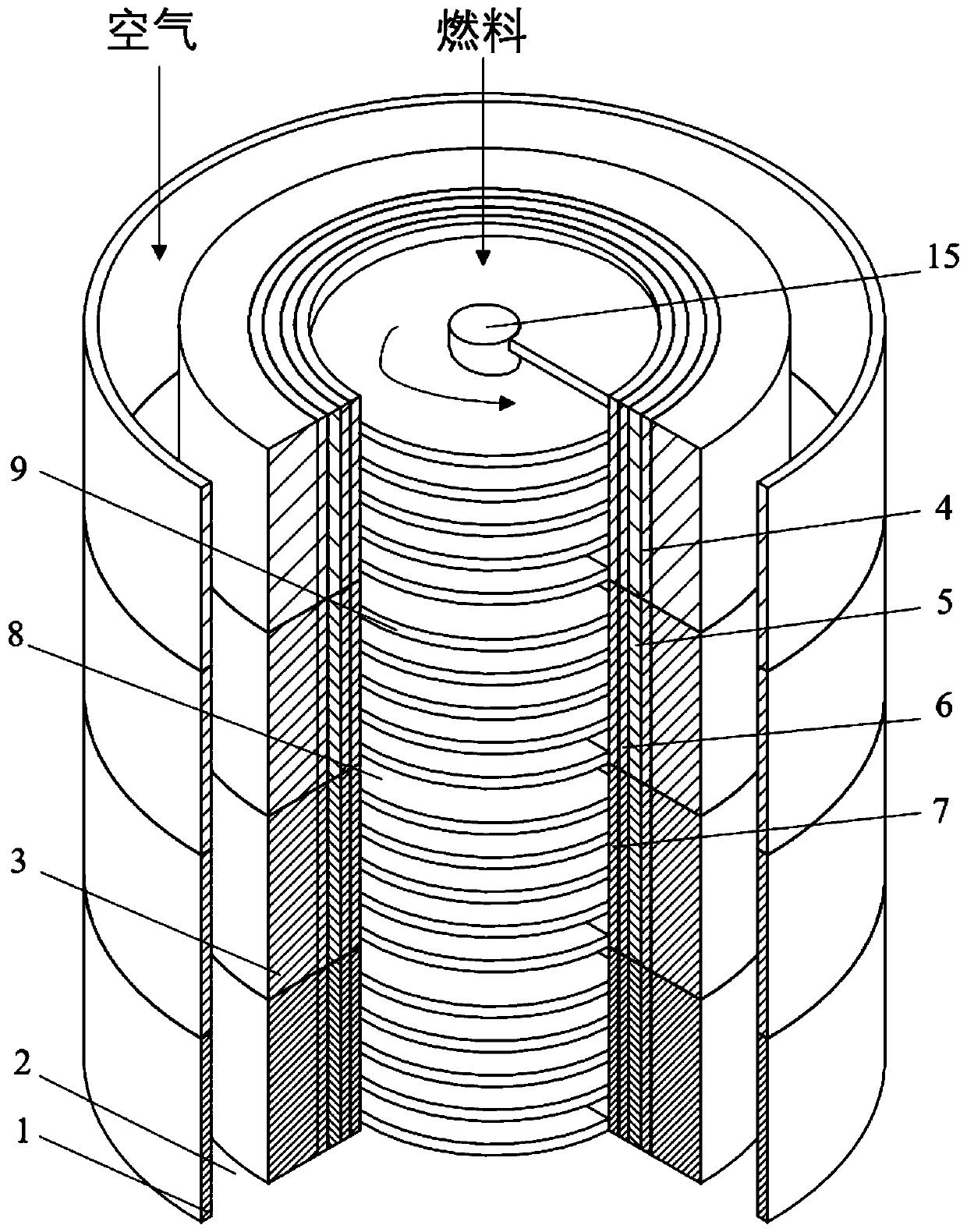

[0044] like Figure 1 to Figure 6As shown, a tubular solid oxide fuel cell structure of the present invention uses high-temperature methane reformed gas as fuel, at least the cathode, anode and electrolyte structure, and the anode gas formed by the outermost shell structure and the anode electrode support layer Channel 2, into which high-temperature reforming gas is introduced; the innermost axis channel is cathode gas channel 8, wherein air is introduced into; the reaction gas in the cathode and anode gas channels 2 is introduced through the cathode and anode electrode support layer 3 The reaction area where the conversion of chemical energy into electrical energy takes place.

[0045] Its outermost shell should have good heat insulation, or its outermost shell should be covered by a material with good heat insulation. The anode, cathode and electrolyte layer 5 should have good heat resistance. The electrode support layer is porous to ensure that the reaction gas can reach ...

Embodiment 2

[0052] figure 2 It is a structural schematic diagram of the SOFC unit of the present invention.

[0053] figure 1 It is a cross-sectional view of a quarter of an example of an axially bisected tubular SOFC of the present invention.

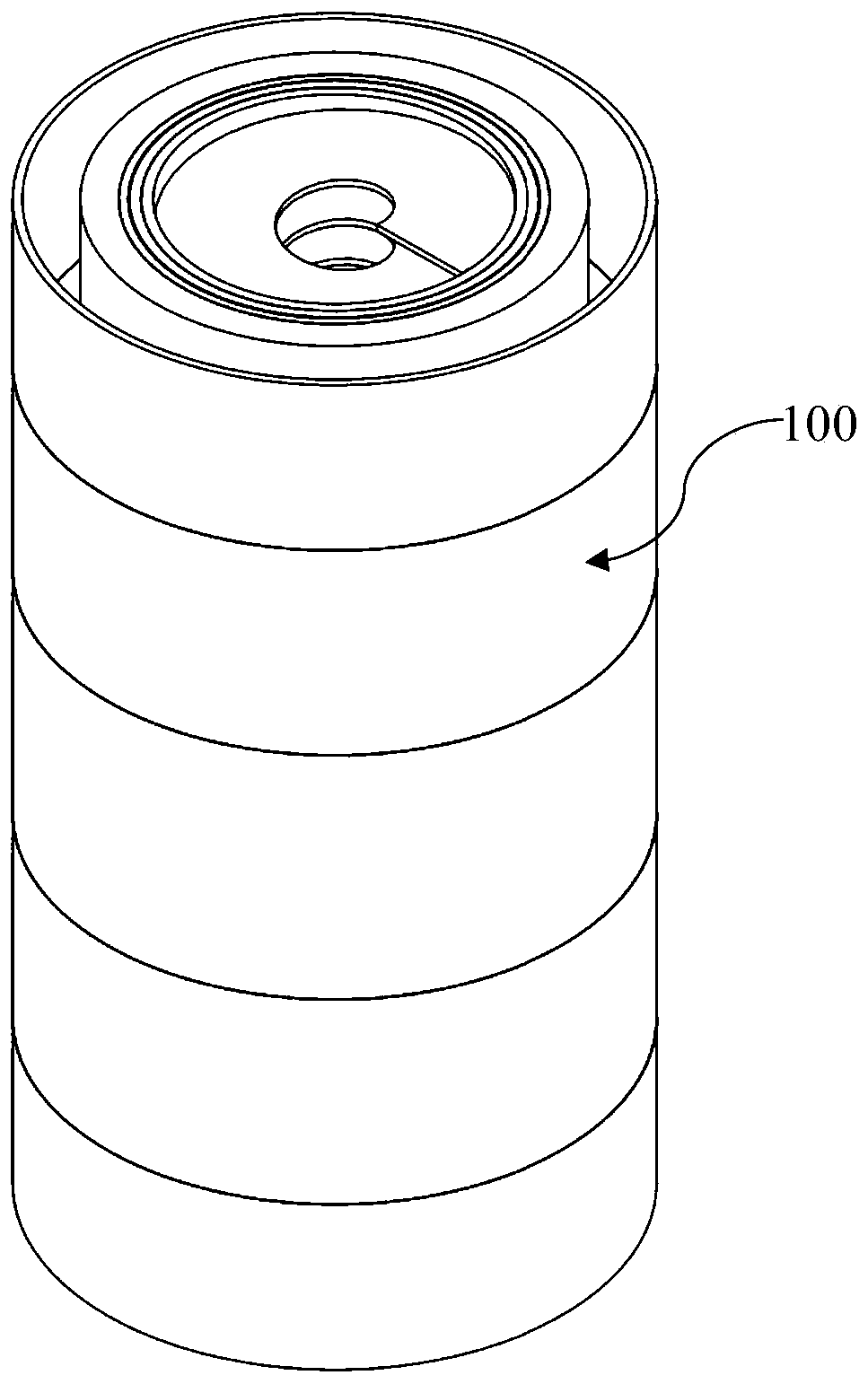

[0054] image 3 and Figure 4 It is a three-dimensional schematic diagram and a full cross-sectional view of an example of axial unequal division of the tubular SOFC of the present invention.

[0055] The SOFC involved in the present invention has a tubular structure, and the anode and cathode of the battery are respectively arranged outside and inside the circular tube. The layers from the outside to the inside along the radius of the circular tube are: battery casing 1, anode gas channel 2, anode electrode support layer 3, anode reaction layer 4, electrolyte layer 5, cathode reaction layer 6, cathode support layer 7, Cathode gas channel 8, spiral guide fins 9. The outer casing 1 is connected with the porous anode electrode support layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com