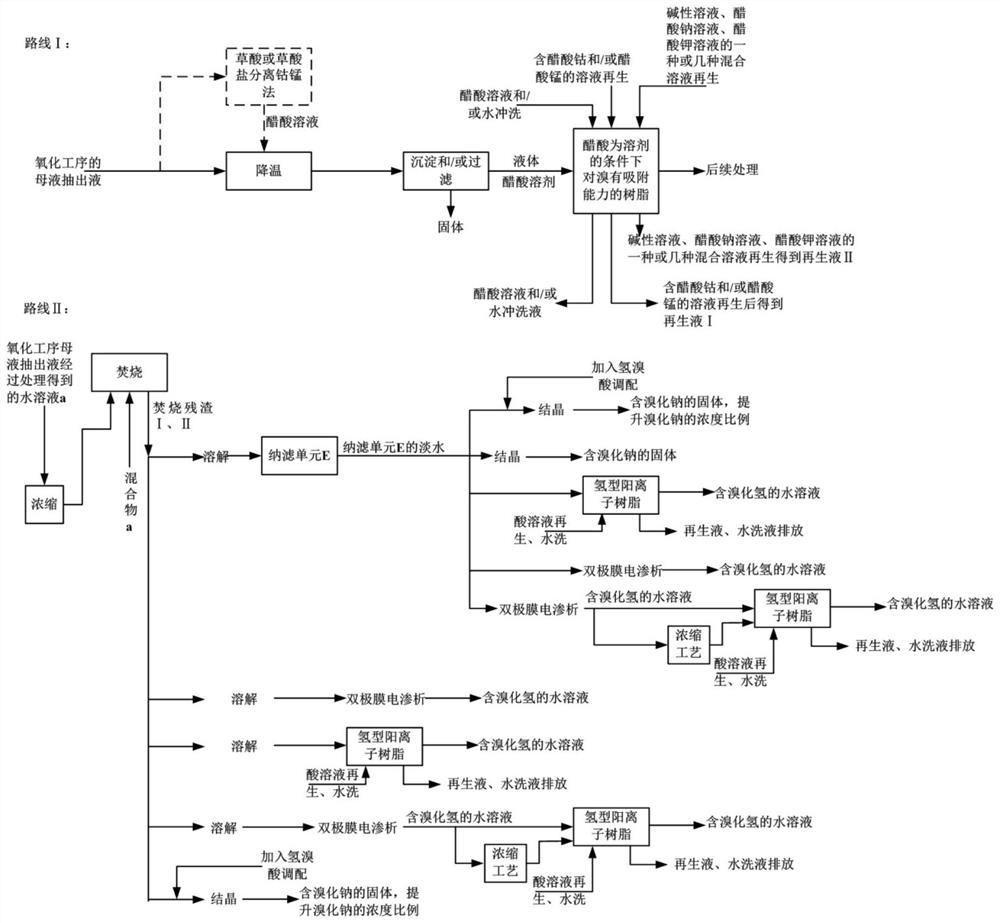

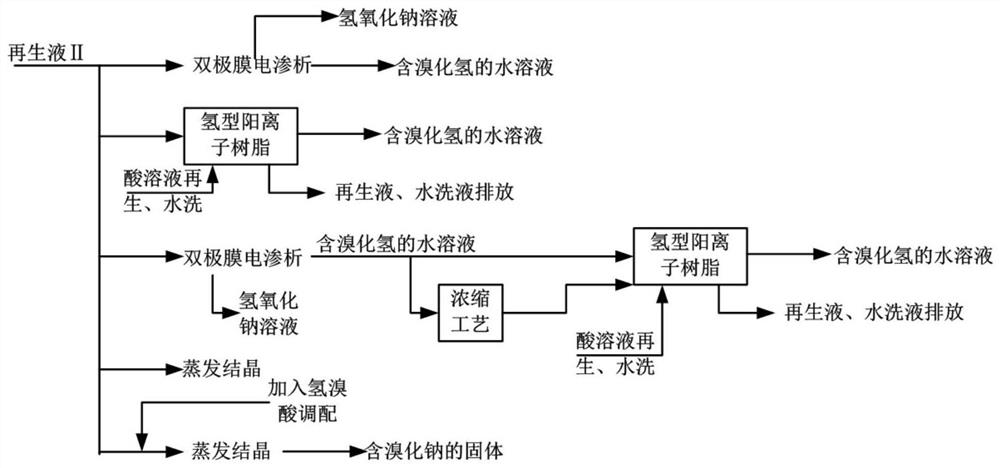

A process for recovering bromine element from the mother liquor extraction liquid in the oxidation process of a terephthalic acid production unit

A technology for terephthalic acid and production equipment, which is applied in the field of bromine element recovery, and can solve the problems of increased equipment footprint, increased cumulative concentration, and increased operating consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Sampling of the mother liquor extract from the oxidation process of the terephthalic acid production plant was filtered through a conventional 5um filter, and then placed to cool down to normal temperature (at that time, the normal temperature was about 20°C), and filtered with an ultrafiltration membrane to obtain the liquid (this example 1 is referred to as liquid A in 1), sampling 800L, analysis composition: acetic acid 86.51%, cobalt ion 571ppm, manganese ion 328ppm, bromide ion 1100ppm, BA 16213ppm, 4-CBA 273ppm, PT acid 753ppm, sodium ion 61ppm, iron ion 6.2ppm , chromium ion 0.93ppm, nickel ion 2.76ppm.

[0128] experiment one

[0129] Liquid A is adsorbed by "resin with adsorption capacity for bromine under the condition of acetic acid solvent", the resin is filled with 10L, the flow rate of liquid A after resin treatment is controlled to 30L / hour, and the concentration in the acetic acid solution after resin treatment at different times is analyzed As shown in t...

Embodiment 2

[0177] Sampling of the filtrate from the oxidation process of the terephthalic acid production plant "the mother liquor extract was passed through the acetic acid removal unit by evaporation, and then the residual mixture was beaten with water and the temperature was lowered to about 95°C, followed by a 5um filter", and then cooled To room temperature (the room temperature was about 20°C at that time), filtrate I was obtained by ultrafiltration membrane filtration, the analysis composition: TA 7569ppm; BA6201ppm; 4-CBA 321ppm; PT acid 433ppm; sodium ion 2572ppm; cobalt ion 3842ppm; 3288ppm; iron ion 4.21ppm; chromium ion 0.46ppm; nickel ion 2.03ppm; acetic acid and its acid radical 12235ppm.

[0178] experiment one

[0179] Treat the filtrate I through the nanofiltration unit A, control the amount of water. Nanofiltration unit A fresh water: nanofiltration unit A concentrated water = 4:1, analyze the nanofiltration unit A fresh water sample: TA4135ppm; BA3162ppm; 4-CBA206ppm; ...

Embodiment 3

[0210] experiment one

[0211] The filtrate I of sampling embodiment 2 is 500L, adding sodium carbonate to promote PH=5.7 to produce a large number of bubbles, no obvious change in volume, with 13 kilograms of sodium carbonate, obtain filtrate II with ultrafiltration, analyze filtrate II: TA7601ppm; BA6188ppm; 4- CBA312ppm; PT acid 419ppm; sodium ion 13059ppm; cobalt ion 3675ppm; manganese ion 3284ppm; bromide ion 3237ppm; iron ion 0.25ppm; chromium ion 0.03ppm;

[0212] Conclusion: In the process of adding sodium carbonate, the concentrations of TA, BA, 4-CBA, PT acid, acetic acid and their acid radicals hardly decrease, and the concentrations of iron ions, chromium ions, and nickel ions decrease to some extent (the ratio of nickel removal to iron ions, chromium ions ions are low).

[0213] Experiment 2

[0214] Treat the filtrate II through the nanofiltration unit B, control the fresh water of the nanofiltration unit B: concentrated water of the nanofiltration unit B = 4:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com