A carbon fiber material integral package lead grid mold based on low density material

A low-density material, carbon fiber material technology, applied in the direction of measuring devices, radiation measurement, instruments, etc., can solve the problems of affecting test data, affecting internal lead slits, collision deformation, etc., to achieve accurate test results, long service life, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

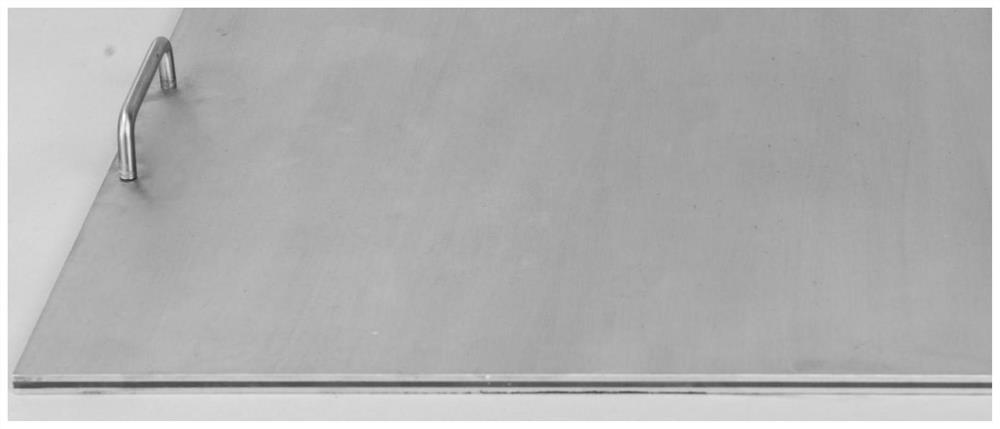

[0028] Such as Figure 5 As shown, a low-density material-based carbon fiber material integrally encapsulates the lead grid mold body, which is mainly composed of two parts: the slit lead plate and the carbon fiber encapsulating the slit lead plate, and the upper, lower and surrounding sides of the slit lead plate are all Encapsulated as a whole using low-density material, the slotted lead plate is not exposed to the environment.

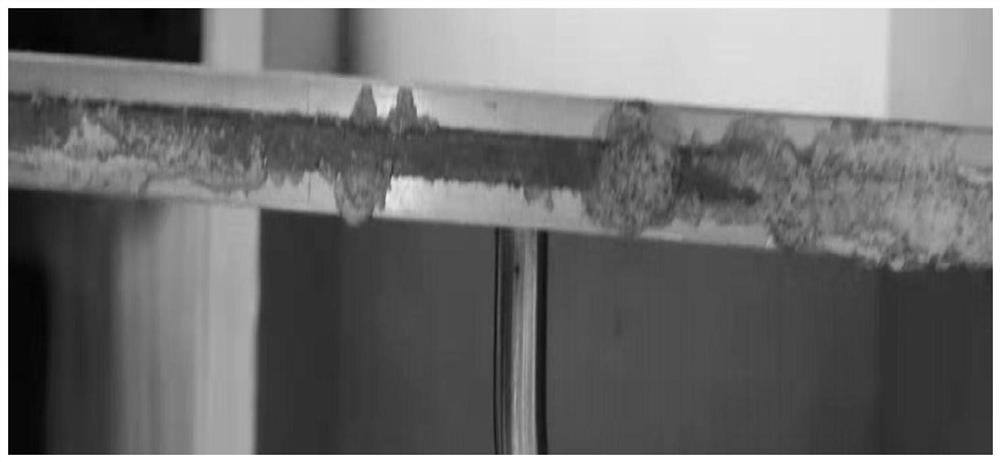

[0029] The slit lead plate of the lead grid mold body is made according to the national standard or international standard, and the flatness is very good. The lead material in the lead grid mold body is extremely demanding. The lead grid contains impurities that lead to inaccurate measurement data. The thickness is not less than 3mm. Several slits are opened on the slit lead plate. The width of the slit is 1mm. The distance between each slit is 30mm. The accuracy is controlled at 0.001mm Lead is a soft metal with small slits and long slits. One sli...

Embodiment 2

[0036] Such as Figure 5 As shown, a carbon fiber material based on a low-density material integrally encapsulates the lead grid mold body, which is mainly composed of two parts: a slit lead plate and a low-density material for encapsulating the slit lead plate. The low-density material is selected from a group with a density not greater than 2.0g / cm 3 Light element composite materials, preferably composite materials such as carbon nitrogen and hydrogen, the upper, lower and surrounding sides of the slit lead plate are all packaged as a whole with low-density materials, and the slit lead plate is not exposed to the environment.

[0037] The slit lead plate is made of pure lead plate with a thickness of not less than 3mm. There are several slits on the slit lead plate with a width of 1mm and a distance of 30mm between each slit.

[0038] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com