Carbonyl-containing covalent organic framework KT-Tp COFs material as well as preparation method and application thereof

A covalent organic framework and carbonyl technology, applied in the field of carbonyl-containing covalent organic framework materials, can solve problems such as poor durability and low capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

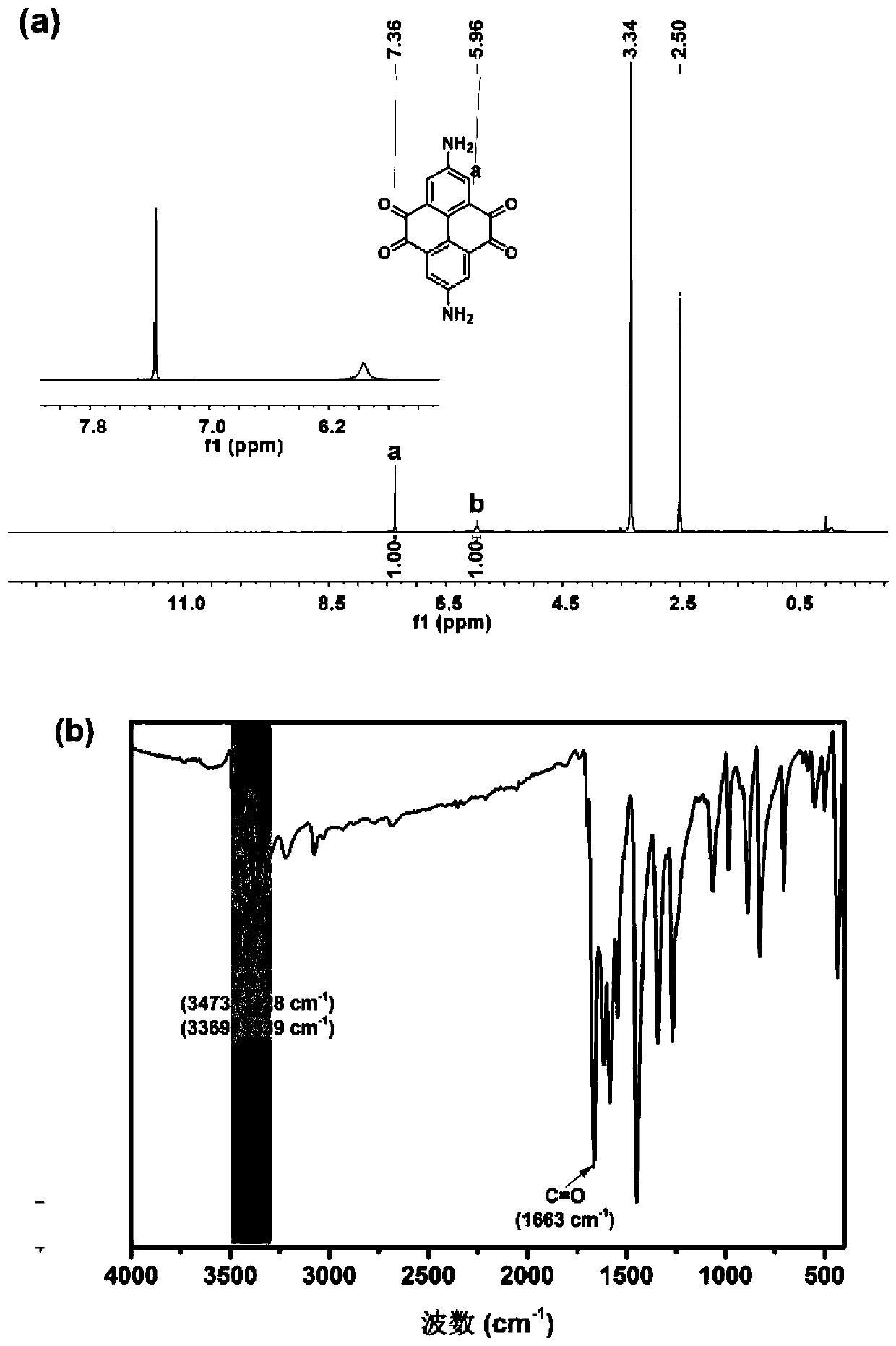

[0049] The preparation method of 2,7-diaminopyrene-4,5,9,10-tetraketone (I-2), comprises the steps:

[0050] 1) Synthesis of pyrene-4,5,9,10-tetraketone (II):

[0051] Pyrene reacts with potassium periodate and ruthenium chloride to generate pyrene-4,5,9,10-tetraketone (II); according to the literature J.Org.Chem.2005,70,707-708.

[0052] 2) Synthesis of 2,7-dinitropyrene-4,5,9,10-tetraketone (III):

[0053] Weigh pyrene-4,5,9,10-tetraketone (II, 5g, 3.8mmol) into a 250mL two-neck round bottom flask, add concentrated sulfuric acid (50mL), then slowly add fuming nitric acid (50mL ). The device was placed in an oil bath at 85°C and refluxed for 45 minutes. After the reaction solution was cooled to room temperature, it was poured into a beaker filled with ice. After the ice was completely melted, it was suction filtered. The filter cake was washed with water and dried in vacuum at room temperature. , to obtain light yellow solid 2,7-dinitropyrene-4,5,9,10-tetraketone (III) (5....

Embodiment 2

[0060] A method for preparing a carbonyl-containing covalent organic framework KT-Tp COFs material ((IV-1), abbreviated as 2KT-Tp COF), comprising the following steps:

[0061] In a 10 mL Schlenk tube, mix 2,7-diamino-9,10-phenanthrenequinone (I-1, 17.9 mg, 0.075 mmol) and 1,3,5-triformylphloroglucinol (V, 10.5 mg, 0.05mmol) was dispersed in a mixed solution of 1,4-dioxane (0.2mL) and mesitylene (0.8mL); sonicated for 2min to obtain a uniform dispersion, and then 0.1mL of 36% acetic acid was added Aqueous solution, sonicated for 2 minutes, frozen and degassed under argon three times, placed the Schlenk tube at 120°C for 3 days, cooled to room temperature, filtered to collect the precipitate, and successively washed with N,N-dimethylacetamide, Washed with tetrahydrofuran and acetone, dried in vacuo to give a black powder (IV-1, 26 mg, yield 91%).

[0062]

[0063] figure 2 The powder XRD diffraction pattern of 2KT-Tp COF prepared in Example 2 proves that 2KT-Tp COF is a t...

Embodiment 3

[0065] A method for preparing a carbonyl-containing covalent organic framework KT-Tp COFs material ((IV-2), abbreviated as 4KT-Tp COF), comprising the following steps:

[0066] In a 10 mL Schlenk tube, mix 2,7-diaminopyrene-4,5,9,10-tetraketone (I-2, 21.9 mg, 0.075 mmol) and 1,3,5-triformylphloroglucinol ( V, 10.5mg, 0.05mmol) was dispersed in 1,4-dioxane (10mL); sonicated for 2min to obtain a uniform dispersion, then added 0.2mL of 36% acetic acid aqueous solution, sonicated for 2min, and frozen And degas three times under argon, put the Schlenk tube at 120 ° C for 3 days, after cooling to room temperature, filter to collect the precipitate, wash with N,N-dimethylacetamide, tetrahydrofuran and acetone successively, and vacuum dry , to obtain a black powder (IV-2, 29 mg, yield 89%).

[0067]

[0068] image 3 The powder XRD diffraction pattern of 4KT-Tp COF prepared in Example 3 proves that 4KT-Tp COF is a two-dimensional covalent organic framework material with good crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com