Preparation method of multilayer reverse osmosis composite membrane

A reverse osmosis composite membrane and reverse osmosis membrane technology are applied in the field of preparation of multi-layer reverse osmosis composite membranes, which can solve the problems of decreased water flux through the membrane, mechanical damage and wear on the membrane surface, and achieves simple process and mild conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

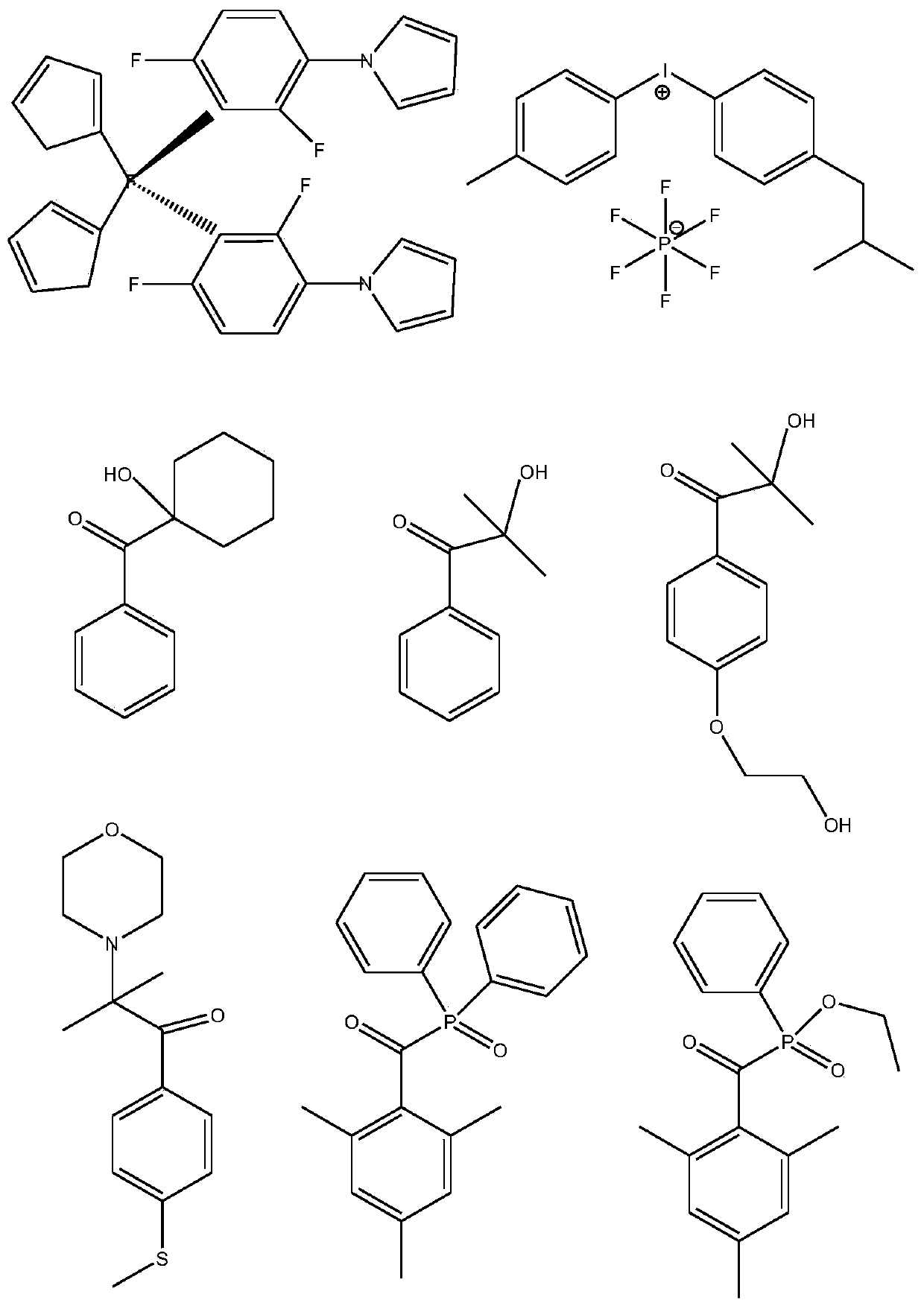

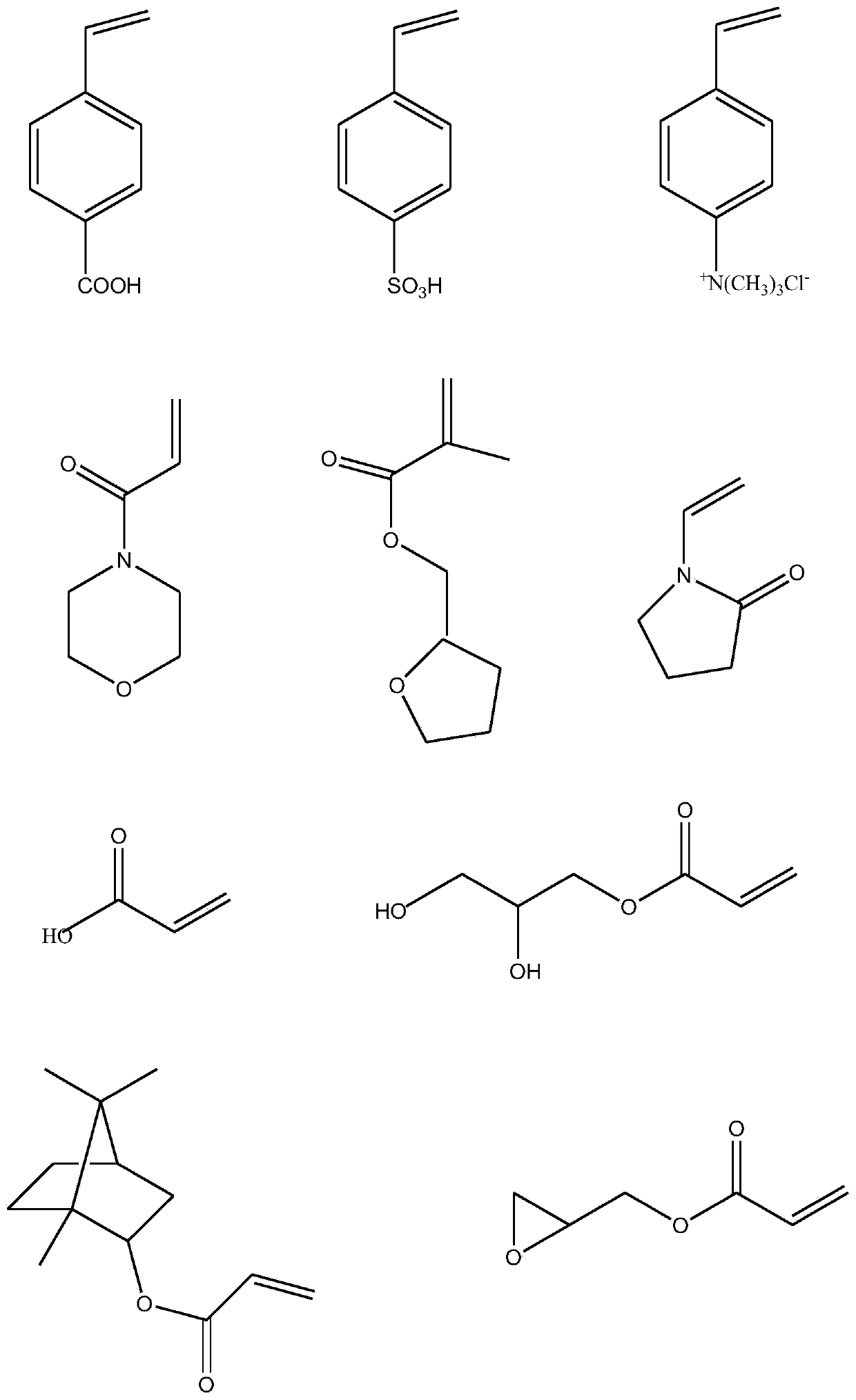

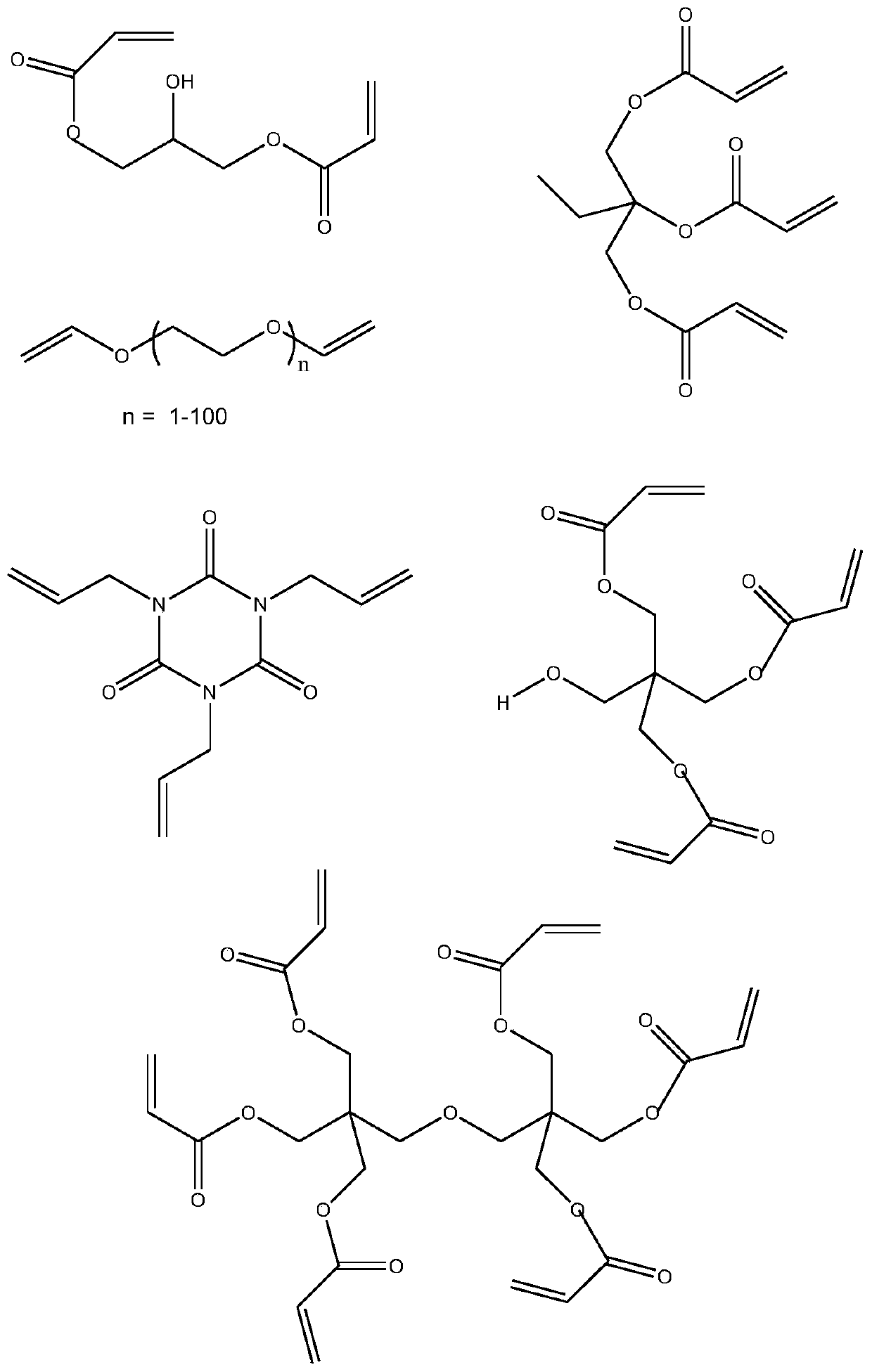

[0048] The preparation principle of the multilayer reverse osmosis composite membrane is as follows:

[0049] When preparing a multi-layer reverse osmosis composite membrane, first select a fabric or non-fabric that meets the requirements of compressive and tensile strength with a width of 1.06 meters and a thickness of 80 microns as the base layer; A 60-micron-thick solution containing organic polymers or inorganic polymers or organic-inorganic composite materials changes from liquid to solid through solvent exchange or temperature changes or phase changes caused by chemical reactions, forming a transition with ultrafiltration membrane separation performance layer; secondly, on the transition layer, form a dense separation layer that can retain sodium chloride ions as small as sodium chloride ions through an online interface reaction; finally, use photoinitiated polymerization on the separation layer to coat a layer of The protective layer of the structure protects the separa...

Embodiment 1

[0073] Preparation of coating solution (transition layer solution):

[0074] Take 20 parts of chemical reagent AZ and 2 parts of AV and add them to 78 parts of AW under stirring, stir at 110°C for 6 hours until AZ is completely dissolved to form a uniform coating solution, and then cool and degas naturally before use.

[0075] Preparation of base film (transition layer):

[0076] JT-100 multi-purpose automatic film coating machine is used, which is 30 meters long, 6 meters high and 5 meters wide. The above coating solution is evenly coated on the polyester non-woven fabric, and the water phase is used for solvent exchange and then solidified to obtain The polysulfone ultrafiltration membrane with non-woven fabric as the base layer is used as the base membrane of the multi-layer reverse osmosis composite.

[0077] Preparation of the separation layer:

[0078] Take 5 parts of chemical reagent AX, 0.5 part of chemical reagent T, dissolve in 94.5 parts of water to form an aqueou...

Embodiment 2

[0085] The present invention systematically studies and optimizes the influence of the protective layer formed by photoinitiated polymerization on the performance of the film, and the obtained representative results are given in Case 2-10.

[0086] The chemical reagents C, L and V in Table 2, although the absorption wavelengths are different, are all highly efficient ultraviolet photoinitiators, which can be used alone or in combination, and the combined use is often more efficient than the single use. After absorbing ultraviolet radiation energy, free radicals are formed to initiate polymerization, crosslinking and grafting reactions of monomers and oligomers, and the coating is cured to form a three-dimensional network structure in a short time. Unfortunately, the solubility of chemical reagents C, L and V in water is very limited, and it is difficult to prepare an aqueous coating system according to conventional methods. In order to solve the problem of its solubility in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com