Micro-roughened electrolytic copper foil and copper-clad substrate using the same

A technology of electrolytic copper foil and copper-clad substrate, which is applied in the secondary treatment of printed circuits, the improvement of metal adhesion of insulating substrates, printed circuits, etc. Back-end product yield and other issues to achieve the effect of reducing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

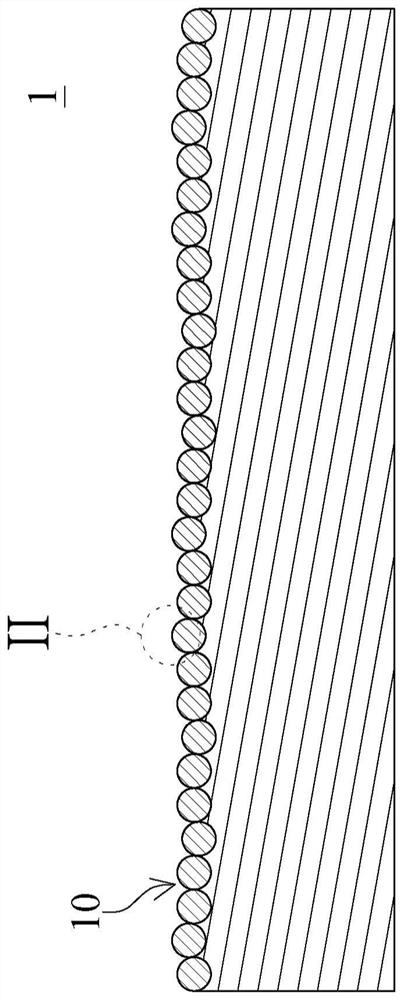

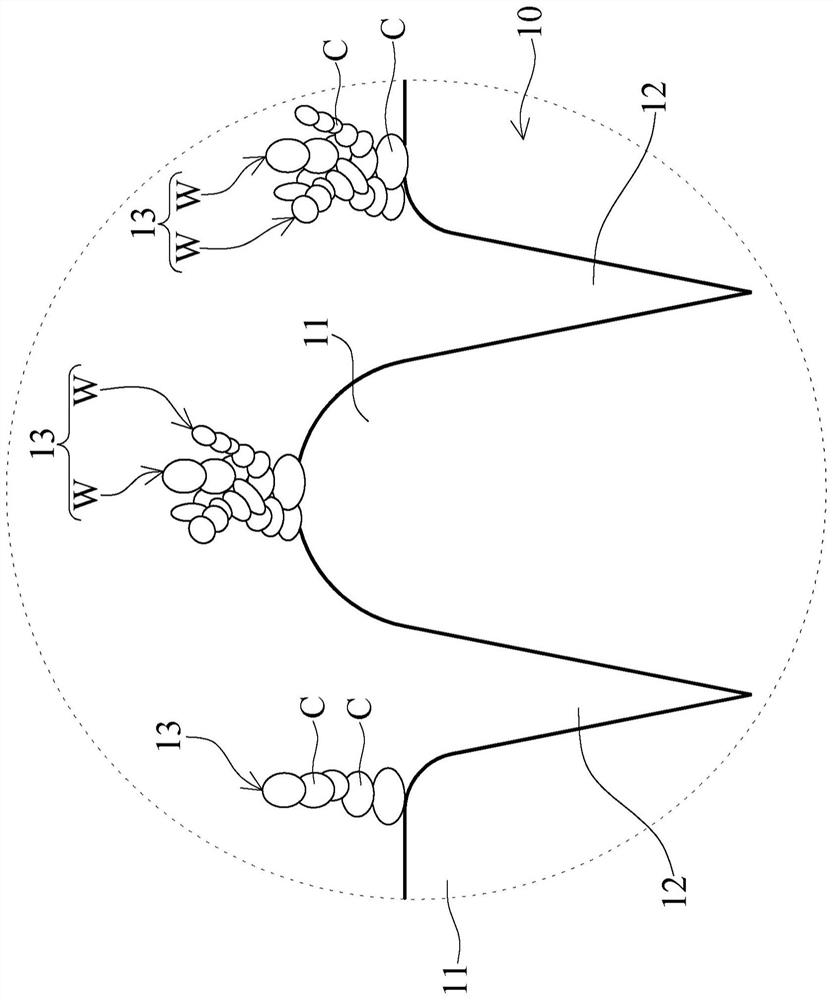

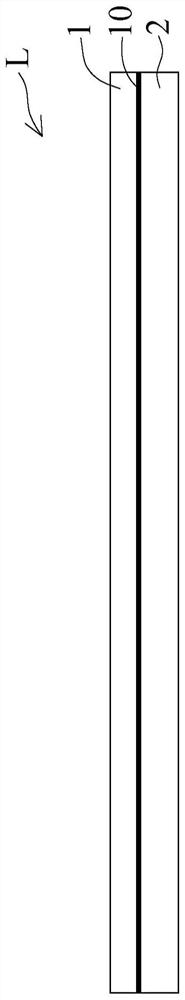

[0040] see Figure 4 and cooperate Figure 5 As shown, the micro-roughened surface 10 of the micro-roughened electrolytic copper foil 1 is formed by using a continuous electrolytic device 3 . The continuous electrolysis device 3 comprises a feeding roller 31, a receiving roller 32, a plurality of electrolytic cells 33 arranged between the feeding roller 31 and the receiving roller 32, a plurality of electrolytic roller groups 34 respectively arranged on the electrolytic cell 33 top and A plurality of auxiliary roller sets 35 are respectively arranged in the electrolytic tank 33 . Wherein, each electrolytic cell 33 is provided with a group of electrodes 331 (such as platinum electrodes), each electrolytic roller group 34 includes two electrolytic rollers 341, and each auxiliary roller group 35 includes two auxiliary rollers 351, and each electrolytic cell 33 The inner electrodes 231 are electrically connected with the corresponding electrolytic roller set 34 to an external po...

Embodiment 2 and 3

[0046] The composition of the base foil, electrolytic device and copper-containing electrolyte is the same as that of Example 1, and the operating conditions are shown in Table 1. The base foil is electrolytically roughened at a production speed of 10 m / min. A piece of electrolytic copper foil 1 subjected to micro-roughening treatment was taken to measure its Sa value and Spd value. The method used was the same as in Example 1, and the results are listed in Table 2. In addition, two pieces of electrolytic copper foil 1 subjected to micro-roughening treatment were bonded to one substrate 2 (low-loss prepreg material, model S7439G) to form a copper-clad substrate L, and then its peel strength was measured. The method and implementation Example 1 is the same, and the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com