Low-cost environment-friendly sand fixing agent and preparation method thereof

An environment-friendly, sand-fixing agent technology, applied in the field of sand-fixing, can solve the problem of high cost, and achieve the effects of low cost, favorable plant growth, and improved water retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

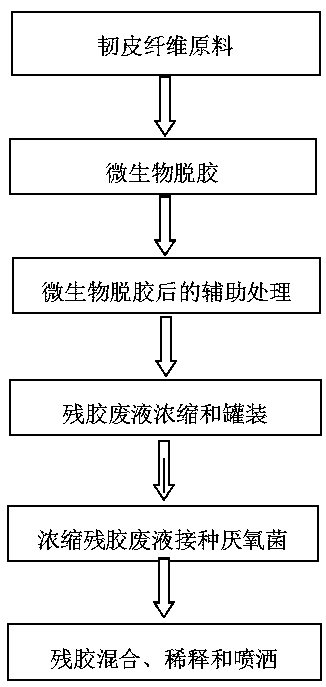

Method used

Image

Examples

preparation example Construction

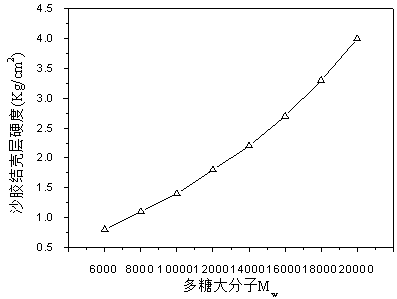

[0036]The polysaccharides produced by bast fiber degumming are wastes in the processing process and can be used directly without extraction, separation and purification, which has a cost advantage. There are many degumming methods for bast fibers, including physical degumming, chemical degumming and microbial degumming. Compared with the residual rubber obtained by other degumming methods, the residual rubber waste obtained by the microbial degumming method has outstanding application advantages. It is reflected in: (1) The degumming process does not use chemical reagents, and the subsequent processing steps are simple. Due to the use of various enzymes produced by Bacillus to soften, loosen, and remove colloids, no chemical reagents are used, and there are no large amounts of acids, alkalis, oxidants or surfactants in the residual plastic waste, and there is no need to increase sand-fixing agents in subsequent preparations. steps to remove these chemicals. (2) The molecular...

Embodiment 1

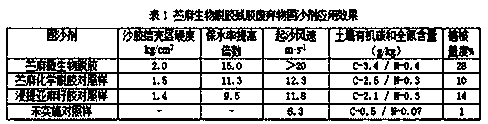

[0054] Put ramie raw hemp, soda ash, ammonium sulfate, dipotassium hydrogen phosphate and water into the degumming tank according to the ratio of 140:6:2:1:1200 by weight; heat up to 120°C and sterilize for 20 min; Bacillus subtilis was inoculated into the degumming tank, and it was aerated and fermented at 40°C for 8 h to obtain microbial degumming residual gum waste liquid A1, which was canned into a closed container. When directly applied as a sand-fixing agent, dilute microbial degumming residual glue waste A1 with water to 3 times the original volume, stir evenly at 200 r / min, spray on the surface of the sand, and spray at a rate of 200 g / m 2 . The application effect of sand fixation is shown in Table 1.

[0055]

[0056] Note: The experimental site is the desertified sandy land in the Horqin area of Inner Mongolia. The pH of the ramie chemical degumming and sand-fixing agent was adjusted to neutral before application; the linseed gum was obtained by water extracti...

Embodiment 2

[0059] Put ramie raw hemp, soda ash, ammonium sulfate, dipotassium hydrogen phosphate and water into the degumming tank according to the ratio of 140:6:2:1:1200 by weight; heat up to 120°C and sterilize for 20 min; Basic Bacillus subtilis was inoculated into the degumming tank, aerated and fermented at 40°C for 8 hours to obtain residual rubber waste liquid, concentrated at room temperature under 0.09MPa negative pressure to 1 / 6 of the original volume, and concentrated residual rubber waste liquid A2 was obtained, which was filled in cans until airtight container. The bast fibers after microbial degumming are subjected to the steps of fiberizing, rinsing and water washing successively to obtain residual rubber waste liquid in the rinsing stage, which is concentrated to 1 / 10 of the original volume at room temperature under 0.09MPa negative pressure to obtain concentrated residual rubber waste liquid B2, tank Pack into an airtight container. Add 10% sucrose to the concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com