Preparation method of olive oil powder, and olive oil powder

A technology of olive oil and powder, which is applied in food forming, edible oil/fat, and fat-containing food ingredients, etc. It can solve the problems of poor taste, easy to oxidize and deteriorate, and short shelf life for direct drinking, so that it is not easy to break Effects of leakage and oxidation, improvement of embedding performance, and extension of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

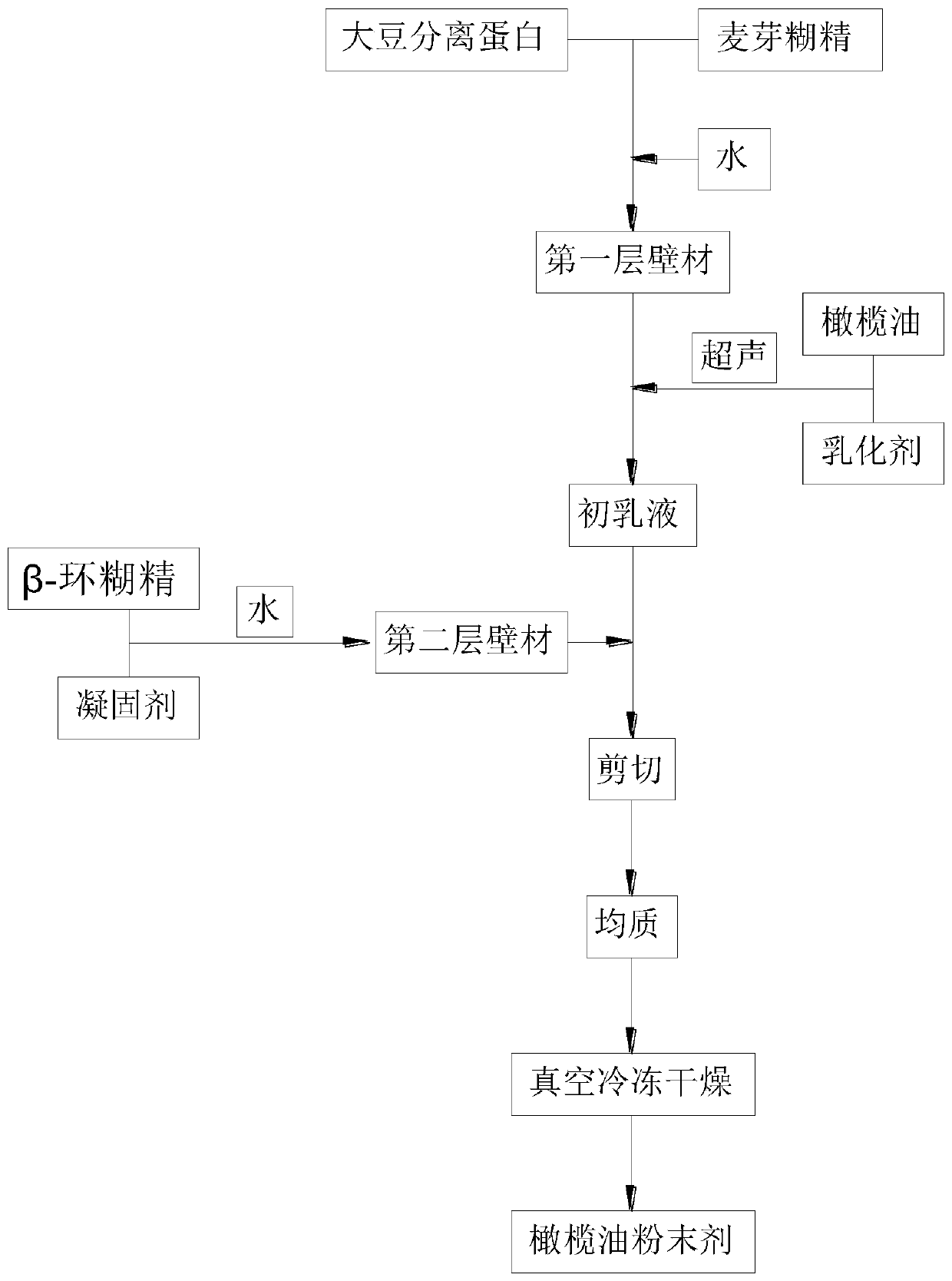

[0038] Such as figure 1 Shown, the preparation method of olive oil powder is about to embedding olive oil as the method in core material and wall material. The concrete steps of its preparation method are as follows:

[0039] Step 1: Preparation of the first layer of wall material

[0040] Weigh soybean protein isolate and maltodextrin with a weight ratio of 1:1.3 to 1:1.8, add to water, stir and dissolve to obtain the first layer of wall material solution, ie solution A, and set aside. Wherein, the weight ratio of the soybean protein isolate and maltodextrin composition to water is 1:2.5˜1:5.

[0041] Step 2: Olive Oil Emulsion Preparation

[0042] Weigh lecithin and Tween-80 with a weight ratio of 5:2, add a small amount of water, fully stir and dissolve to obtain an emulsifier; measure olive oil, add the prepared emulsifier to olive oil, olive oil and emulsification The weight ratio of the agent is 1:0.001~1:0.0025. After fully stirring and mixing, put it into the ultra...

Embodiment 2

[0055] The preparation method of olive oil powder, its concrete steps are as follows:

[0056] Step 1: Preparation of the first layer of wall material

[0057] Weigh 40g of soybean protein isolate and 60g of maltodextrin, add to 400ml of water, stir and dissolve to obtain the first layer of wall material solution, namely A solution, and set aside;

[0058] Step 2: Olive Oil Emulsion Preparation

[0059] Weigh 0.5g lecithin and 0.2g Tween-80, add into 20ml water, fully stir and dissolve to make emulsifier; take beaker, measure 350ml olive oil, add the prepared emulsifier into olive oil, stir well After uniformity, put it into an ultrasonic emulsification machine, the ultrasonic power is 100W, and ultrasonic treatment is 10min, and the olive oil emulsion is obtained, namely the B solution, which is set aside.

[0060] Step 3: Preparation of the second layer of wall material

[0061] Take a beaker, add 450ml of water, heat to 80-90°C, weigh 33g of β-cyclodextrin, 60g of psylli...

Embodiment 3

[0072] Prepare olive oil powder, concrete steps are as follows:

[0073] Step 1: Preparation of the first layer of wall material

[0074] Weigh 40g of soybean protein isolate and 55g of maltodextrin, add to 250ml of water, stir and dissolve to obtain the first layer of wall material solution, i.e. solution A, and set aside;

[0075] Step 2: Olive Oil Emulsion Preparation

[0076] Weigh 0.5g lecithin and 0.2g Tween-80, add to 20ml water, fully stir to dissolve, and make an emulsifier; take a beaker, measure 300ml olive oil and 30ml honey, add the prepared emulsifier to olive oil and honey After fully stirring and mixing, put it into an ultrasonic emulsification machine with an ultrasonic power of 100W and ultrasonic treatment for 15 minutes to obtain an olive oil emulsion, namely solution B, for future use.

[0077] Step 3: Preparation of the second layer of wall material

[0078] Take a beaker, add 300ml of water, heat to 80-90°C, weigh 14g of β-cyclodextrin and 60g of agar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com