High-silicon high-temperature titanium alloy and preparation method thereof

A high-temperature titanium alloy and high-silicon technology, which is applied in the field of high-silicon high-temperature titanium alloy and its preparation, can solve the problem that the service temperature of casting high-temperature titanium alloy is difficult to exceed 600°C, and achieve excellent high temperature, simple preparation method, and uniform and fine structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

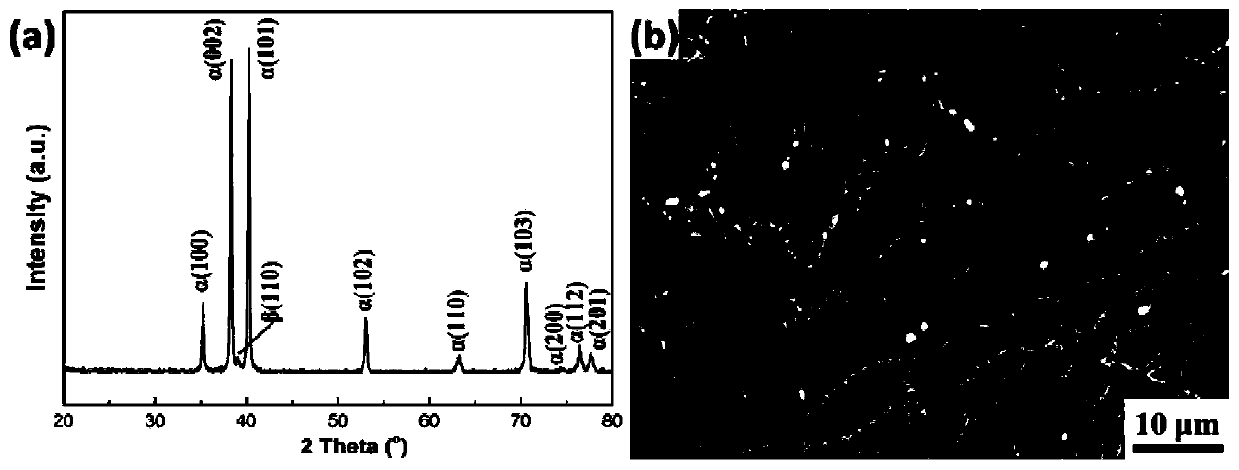

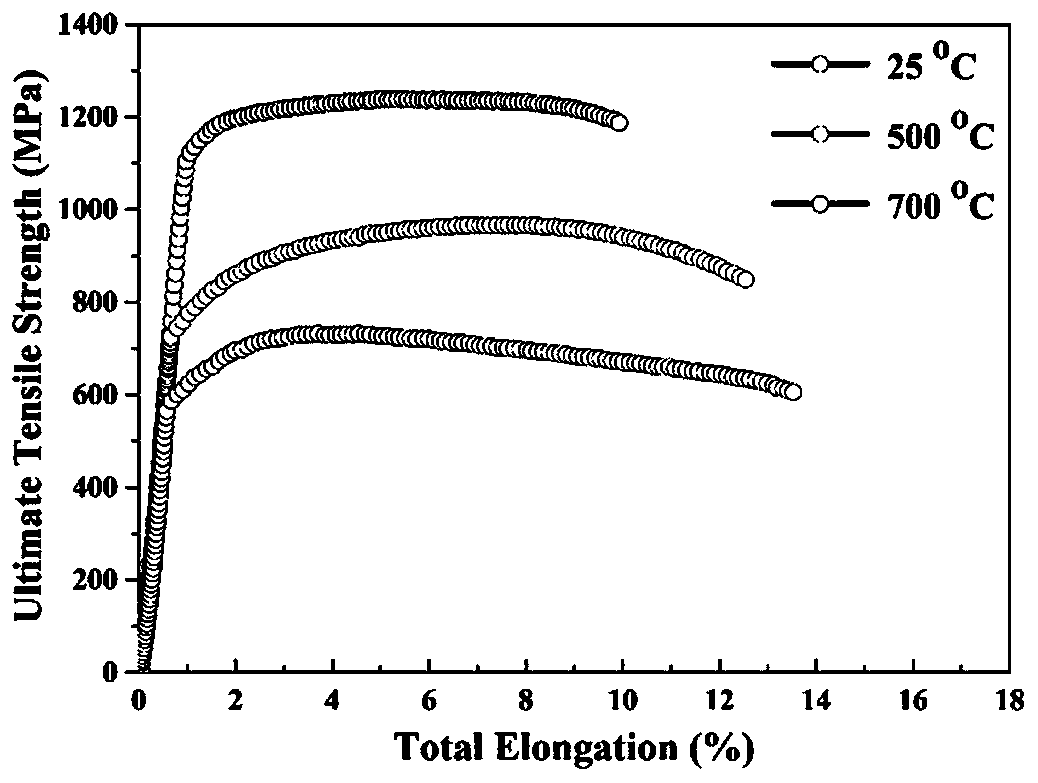

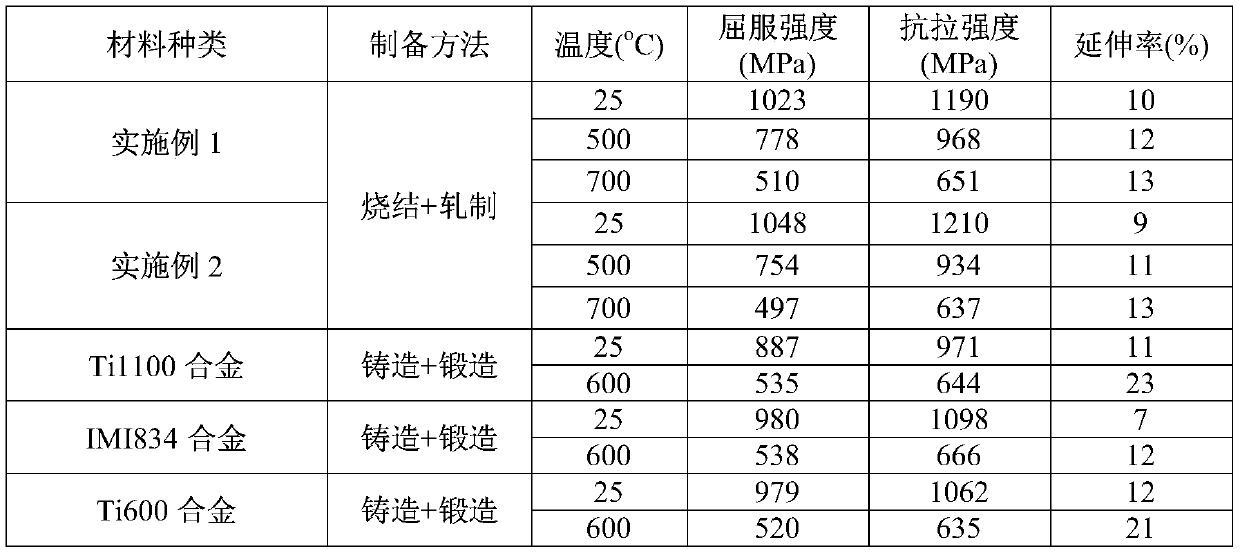

[0030] Using hydrodehydrogenated Ti powder, gas-atomized Al powder, Zr powder, Sn powder, Mo powder and Si powder as raw materials, the contents in terms of mass percentage are Al: 6%, Zr: 4%, Sn: 3.5%, Mo : 0.5%, Si: 0.6%, and the balance is Ti. Each powder was weighed, placed in a V-shaped mixer and fully mixed for 6 hours under the protection of argon with a rotation speed of 30 r / min. Fill the mixed powder to d30×300mm 3 In the cylindrical rubber tube, after vibration and compaction, the pressure was kept at 200MPa for 12 minutes for cold isostatic pressing to form a cylindrical compact. At 1300°C, the vacuum degree is higher than 1×10 -3Sintering under the condition of Pa for 2h, the specific process of sintering: room temperature → (90min) 750°C → (40min) 1000°C → (120min) 1350°C → (furnace cooling), to obtain sintered rods. Place the sintered bar in a resistance furnace and heat it to 950°C for 30 minutes. After rolling for multiple passes, it is made into an alloy p...

Embodiment 2

[0034] Using hydrogenated dehydrogenation Ti powder, gas-atomized Al powder, Zr powder, Sn powder, Mo powder and Si powder as raw materials, the contents in terms of mass percentage are Al: 5.4%, Zr: 3.8%, Sn: 4%, Mo : 0.7%, Si: 1.0%, and the balance is Ti. Weigh each powder, put it in a V-type mixer and mix it fully for 6 hours under the protection of argon, and the rotation speed is 30r / min. Fill the mixed powder to d30×300mm 3 In the cylindrical rubber tube, after vibrated and compacted, the pressure was kept at 230MPa for 10 minutes for cold isostatic pressing to form a cylindrical compact. At 1350°C, the vacuum degree is less than 1×10 -3 Sintering under the condition of Pa for 2h, the specific process of sintering: room temperature → (90min) 750°C → (30min) 1000°C → (120min) 1380°C → (furnace cooling) to obtain sintered rods. Place the sintered bar in a resistance furnace and heat it to 900°C for 30 minutes. After rolling for multiple passes, it is made into an alloy p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com