Rosin production and processing technology

A processing technology, rosin technology, applied in the field of rosin processing, can solve the problems of poor aging resistance, light and heat instability, pulverization and discoloration, etc., and achieve the effect of accelerating the dissolution rate, reducing the amount of use, and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

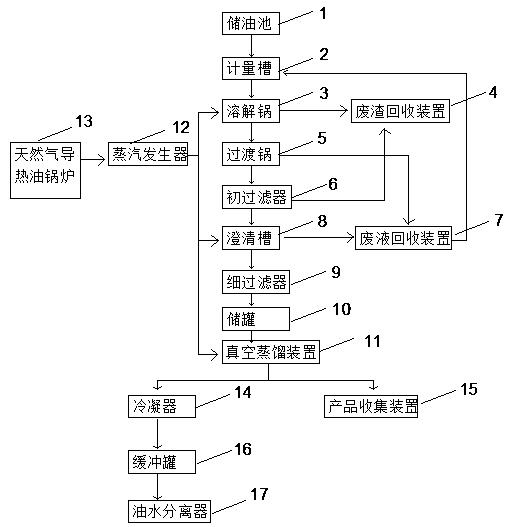

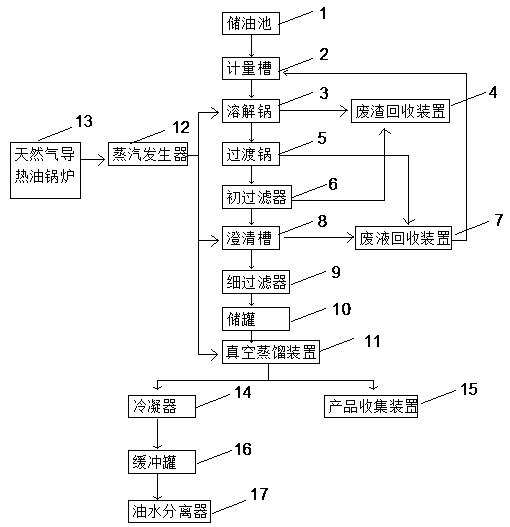

[0024] A rosin production and processing process, the process comprising: a fat storage tank 1, the fat storage tank 1 is connected to a metering tank 2, the metering tank 2 is connected to a dissolving pot 3, and the dissolving pot 3 is respectively connected to a waste residue recovery device 4 and a transition pot 5;

[0025] The transition pot 5 is connected with the primary filter 6 and the waste liquid recovery device 7 respectively, the waste liquid recovery device 7 is connected with the metering tank 2, the primary filter 6 is connected with the clarification tank 8 and the waste residue recovery device 4 respectively, and the clarification tank 8 is connected with the fine filter The device 9 is connected, the fine filter 9 is connected to the storage tank 10, and the storage tank 10 is connected to the vacuum distillation pot 11;

[0026] Dissolving pot 3, clarification tank 8, and vacuum distillation pot 11 are all connected with steam generator 12, and steam genera...

Embodiment 2

[0029]On the basis of embodiment 1, on the pipeline that is connected with condenser 14 on the dissolving pot 3, all be provided with pipeline sight glass; The bore sight glass can observe the completion of grease pressing.

Embodiment 3

[0031] On the basis of embodiment 1-2, between the product collection device 15 and the vacuum distillation pot 11, an incense trough is arranged, and a heat dissipation plate is arranged in the incense trough; the setting of the heat dissipation plate shortens the time for putting incense, improves product quality, and changes Raw material sending incense is placed too long in the vacuum distillation pot 11, causes the color of gum rosin to become darker.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com