Plastic dilatant polymer and method for achieving the dilatant property thereof

A technology of dilatation and polymers, which is applied in the field of plastic dilatation polymers and their realization of dilation, and can solve the problems of inability to carry out plastic reprocessing, large space, difficult customized production and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

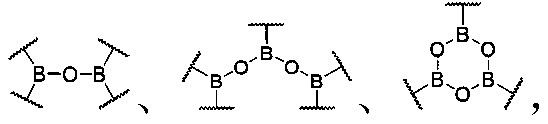

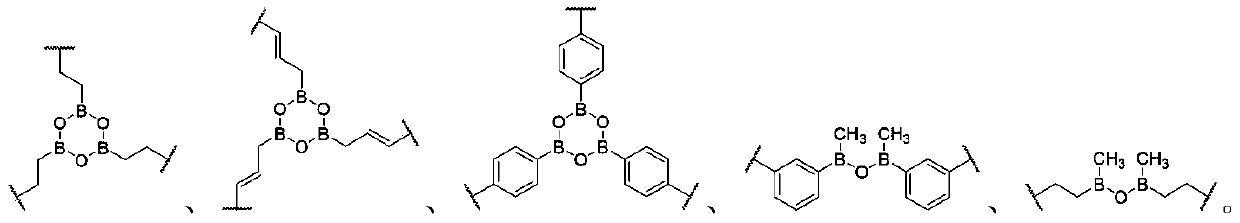

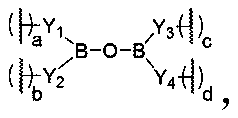

Method used

Image

Examples

preparation example Construction

[0729] In the preparation process of the polymer, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam it.

[0730] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the polymer to make it a uniform foam, and then through physical or Chemical changes shape it into foam. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0731]Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the polymer, which includes but is not limited to the following methods: (1) inert gas foaming method, that is, under pressure Under normal circumstances, the inert gas is pressed into the molten polymer or pasty material, and then the pressure is reduced and the tem...

Embodiment 1

[0755]

[0756] Get 40 molar equivalents of 1-(2-methylaminoethoxy)-4-vinylbenzene, 60 molar equivalents of 1-(2-methylhexyl)-4-vinylbenzene, 0.6 molar equivalents of benzoyl peroxide, place In a reaction vessel, dissolve it with an appropriate amount of toluene, and react with stirring at 70° C. for 24 hours under a nitrogen atmosphere to obtain a polystyrene derivative. Using pyridine as a catalyst and dichloromethane as a solvent, compound (a) is reacted with excess 4-vinylbenzoyl chloride to obtain compound I; then take 100 molar equivalents of 1-(2-methylhexyl)-4 - Ethylene benzene, 3 molar equivalents of compound I, 0.6 molar equivalents of benzoyl peroxide, placed in a columnar container, record the total mass of the above-mentioned reactants as 100wt%, then add 50wt% of the polystyrene derivatives prepared above , 250wt% toluene, stirred and mixed evenly, and reacted at 70° C. for 24 hours under a nitrogen atmosphere to prepare a dilatant polymer organogel. The gla...

Embodiment 2

[0758]

[0759] Using pyridine as a catalyst and dichloromethane as a solvent, compound I is prepared by reacting compound (a) with excess acryloyl chloride. Compound (b) is prepared by reacting hydroxyethyl methacrylate with excess ethyl isocyanate using dibutyltin dilaurate as a catalyst. Take 60 molar equivalents of 1-(2-methoxyethoxy)-4-vinylbenzene, 60 molar equivalents of hydroxyethyl methacrylate, 40 molar equivalents of compound (b), and 5 molar equivalents of compound I in a reaction vessel , dissolved in an appropriate amount of toluene, and then added 1.2 molar equivalents of azobisisobutyronitrile initiator, stirred and reacted at 70° C. for 24 hours under a nitrogen atmosphere to prepare a dilatant polymer organogel. The dilatant gel is rich in strong dynamic cross-linking and has good dilation and energy absorption properties. It is made into a sample with a thickness of 1cm. According to the EN1621-2012 method, the temperature of the sample is measured at 25°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com