Method for preparing magnetic ZSM-5 zeolite from clay and red mud through micro-solvent process

A technology of ZSM-5 and clay, which is applied in the field of zeolite preparation, can solve problems such as difficult to meet actual needs and weak magnetic properties, and achieve the effects of avoiding the use of water and iron salts, strong magnetic properties, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

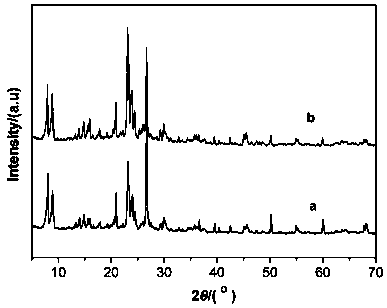

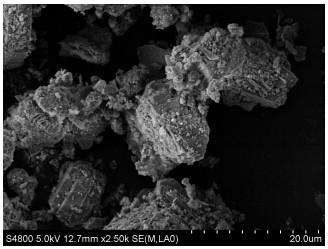

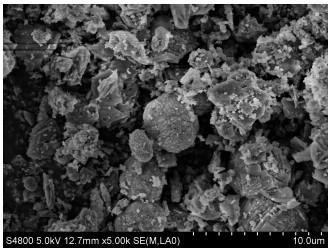

[0025] Disperse 20g of attapulgite in 80 ml of 3mol / L HCl solution, soak at 80°C for 48 h, filter, wash and dry to obtain acidified attapulgite; weigh 1.6g of acidified attapulgite, 0.16g of red mud, 0.4 g ammonium chloride, 0.2g tetrapropylammonium bromide were mixed and ground for 30min to obtain a powder, then 0.5g NaOH and 0.6g H were added to the powder 2 O prepared NaOH solution, stirred evenly to form a paste mixture, sealed and left to stand for 24 hours, then transferred to a sealed reaction kettle, crystallized at 180°C for 4 hours to obtain ZSM-5 zeolite crystals, cooled ZSM-5 zeolite crystals, added water to wash, and suction filtered , After drying, calcined at 550°C for 3 hours to obtain ZSM-5 zeolite, whose crystal form and morphology are as follows figure 1 and figure 2 Shown are ZSM-5 zeolite crystals.

Embodiment approach 2

[0027] Disperse 20g of attapulgite in 80 ml of 3mol / L HCl solution, soak at 80°C for 48 h, filter, wash and dry to obtain acidified attapulgite; weigh 1.6g of acidified attapulgite, 0.28g of red mud, 0.4 G sodium chloride, 0.3g tetrapropylammonium bromide were mixed and ground for 30min to obtain a powder, then 0.6g NaOH and 0.8g H were added to the powder 2 O prepared NaOH solution, stirred evenly to form a paste mixture, sealed and allowed to stand for 24 hours, then transferred to a sealed reaction kettle, crystallized at 180°C for 12 hours to obtain ZSM-5 zeolite crystals, cooled ZSM-5 zeolite crystals, washed with water, and suction filtered , After drying, calcined at 550°C for 3 hours to obtain ZSM-5 zeolite.

Embodiment approach 3

[0029] Disperse 20g of attapulgite in 80 ml of 3mol / L HCl solution, soak at 80°C for 48 h, filter, wash and dry to obtain acidified attapulgite; weigh 1.6g of acidified attapulgite, 0.4g of red mud, 0.4 g ammonium chloride, 0.4g tetrapropylammonium bromide were mixed and ground for 30min to obtain a powder, then 0.6g NaOH and 1g H were added to the powder 2 O prepared NaOH solution, stirred evenly to form a paste mixture, sealed and left to stand for 24 hours, then transferred to a sealed reaction kettle, crystallized at 180°C for 24 hours to obtain ZSM-5 zeolite crystals, cooled ZSM-5 zeolite crystals, washed with water, and suction filtered , After drying, calcined at 550°C for 3 hours to obtain ZSM-5 zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com