A horizontal boring machine

A horizontal boring machine and bed body technology, applied in the field of boring machines, can solve the problems of increasing the workload of the operator, low operation safety factor, easy to scratch the operator, etc., so as to avoid dripping everywhere, reduce the workload, and prevent dirt from sticking. Effects attached to the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

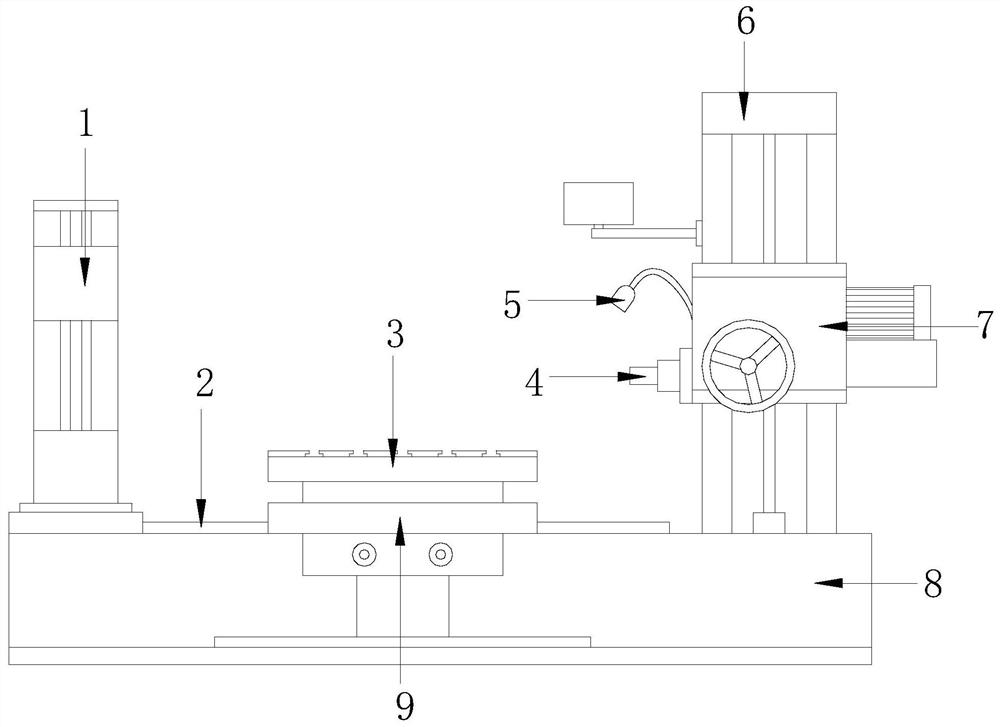

[0036] see figure 1 , the present invention provides a technical solution for a horizontal boring machine: its structure includes a rear column assembly 1, a sliding assembly 2, a workbench 3, a spindle assembly 4, a lighting assembly 5, a front column assembly 6, a headstock 7, a bed 8. The pallet rotating assembly 9, one side of the bed body 8 is vertically connected to the rear column assembly 1, and the other side is vertically connected to the front column assembly 6, and the front column assembly 6 is equipped with a headstock 7 and a lighting lamp assembly 5 , the headstock 7 is connected to the spindle assembly 4, a sliding assembly 2 is provided between the rear column assembly 1 and the front column assembly 6, the sliding assembly 2 is mechanically connected to the bed body 8, and the sliding assembly 2 is slidably connected There is a pallet rotating assembly 9 on which a workbench 3 is mounted;

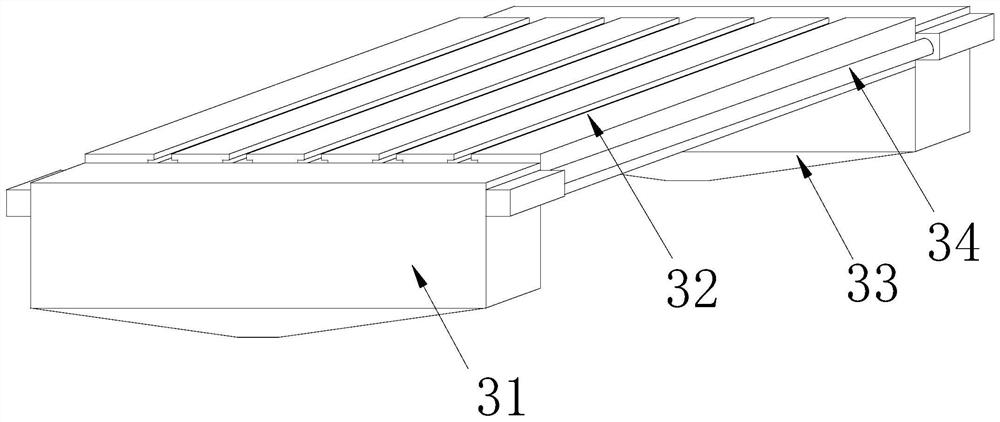

[0037] see figure 2, the workbench 3 includes a water treatment d...

Embodiment 2

[0042] see Figure 1-8 , the present invention provides a technical solution for a horizontal boring machine: its structure includes a rear column assembly 1, a sliding assembly 2, a workbench 3, a spindle assembly 4, a lighting assembly 5, a front column assembly 6, a headstock 7, a bed 8. The pallet rotating assembly 9, one side of the bed body 8 is vertically connected to the rear column assembly 1, and the other side is vertically connected to the front column assembly 6, and the front column assembly 6 is equipped with a headstock 7 and a lighting lamp assembly 5 , the headstock 7 is connected to the spindle assembly 4, a sliding assembly 2 is provided between the rear column assembly 1 and the front column assembly 6, the sliding assembly 2 is mechanically connected to the bed body 8, and the sliding assembly 2 is slidably connected There is a pallet rotating assembly 9 on which a workbench 3 is mounted, and is characterized in that:

[0043] The workbench 3 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com