Pipeline cleaning device

A technology for cleaning devices and pipes, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of complex driving mode, complex structure, easy damage, etc., to improve cutting efficiency and cutting effect, high efficiency Cutting and cleaning effect, the effect of reducing the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

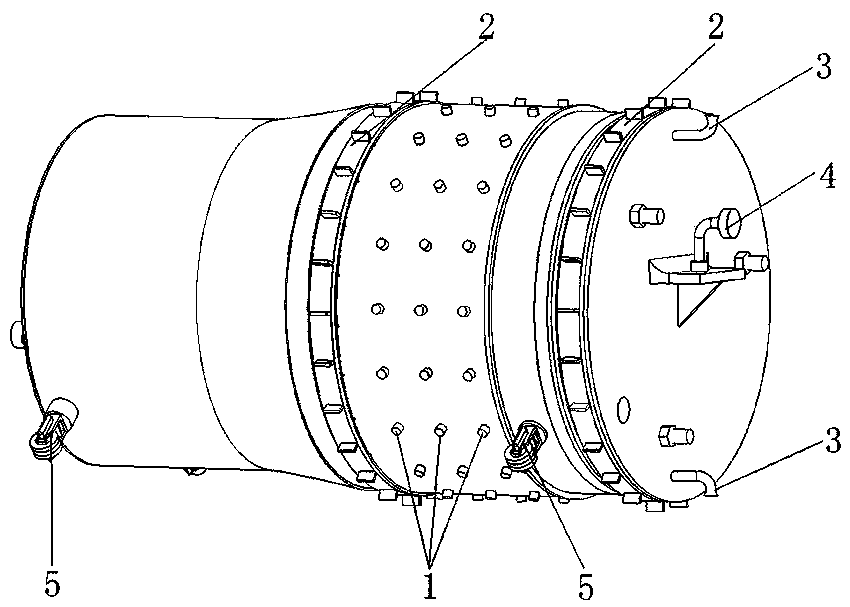

[0032] An embodiment of the present invention provides a pipe cleaning device, the overall appearance of which is nearly cylindrical, which includes the same main body frame as the traditional pipe cleaning device and the walking mechanism, rotary cutter head assembly and garbage collection device all arranged on the main frame In addition, it particularly includes a cooling device arranged on the main body frame. It can be understood that, in practical applications, these structures provided on the main body frame need to be exposed to realize corresponding functions, and the rest of the components are packaged with a protective shell.

[0033] Among them, the walking mechanism is used to drive the entire pipeline cleaning device to move axially along the pipeline; the rotary cutter head assembly is used to cut the deposited stains on the inner wall of the pipeline; the garbage recovery device is used to suck and recycle the cut garbage.

[0034] refer to figure 1 , the cool...

Embodiment 2

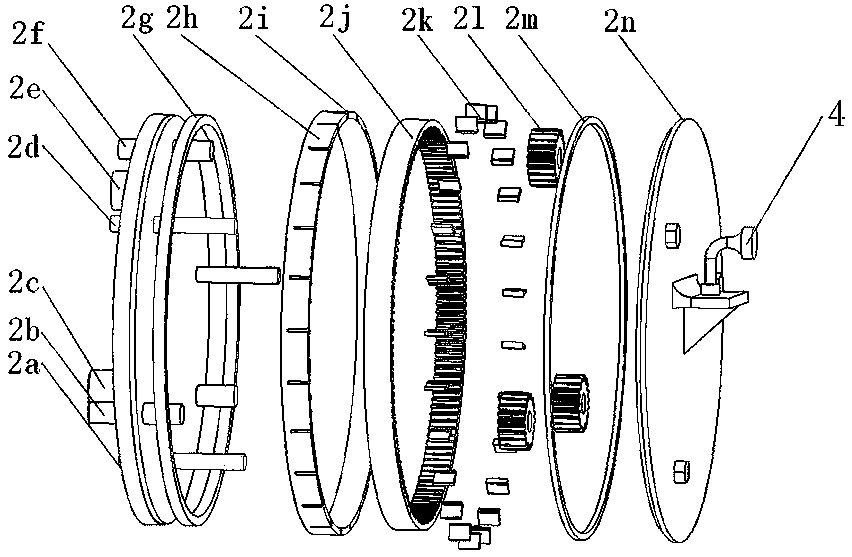

[0039] On the basis of the above-mentioned embodiment 1, the present invention provides a new implementation method for the rotary cutter head assembly. Compared with the prior art, the structure is reasonable, the cutting rigidity is guaranteed, and the cutting efficiency and cutting effect are greatly improved.

[0040] Specifically, refer to figure 1 and figure 2, the rotary cutter head assembly 2 includes an annular blade mounting frame 2h, a plurality of rigid cutting blades 2k uniformly arranged in the circumferential direction on the preset blade mounting opening 2i of the blade mounting frame 2h, and an epicyclic wheel that carries and drives the blade mounting frame 2h to rotate system structure. The main function of the rotary cutter head assembly 2 is to rigidly cut the attachments on the inner wall of the pipeline. The motor drives the fixed gear to rotate, and the fixed gear drives the epicyclic gear to move through transmission, while the epicyclic gear drives ...

Embodiment 3

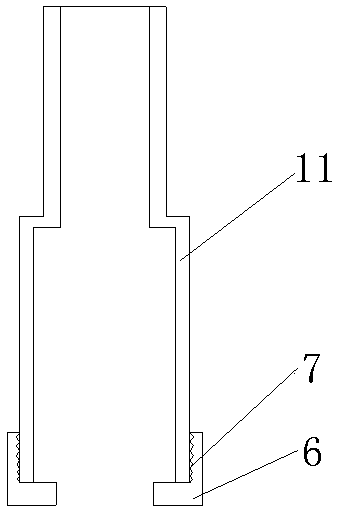

[0045] Based on the contents disclosed in the above-mentioned embodiments, the upper traveling unit of the traveling mechanism in the present invention adopts a magnetic wheel assembly. The magnetic wheel assembly mainly includes a wheel body and a rotating drive component connected to the rotation center axis of the wheel body. The wheel body has a magnet and a pipeline. (Usually iron pipes) generate magnetic attraction force, and then adsorb on the inner wall of the metal pipe to generate friction force. At the same time, due to the existence of friction force, the entire wheel body rotates under the drive of the rotating drive parts to achieve forward and backward movements. . Compared with the crawler drive mode in the prior art, the structure is simple, the drive principle is simplified, and the wear degree of related components is reduced. Considering the existence of deposits (mainly waxy layer) between the running gear and the metal pipe, the running gear should be lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com