A novel oxygen evolution electrocatalyst and its preparation method and application

An electrocatalyst and oxygen evolution technology, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of harsh conditions, electroactivity needs to be improved, and catalyst structure is easy to collapse, so as to achieve good catalytic activity, The effect of improving the performance of electrocatalytic oxygen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

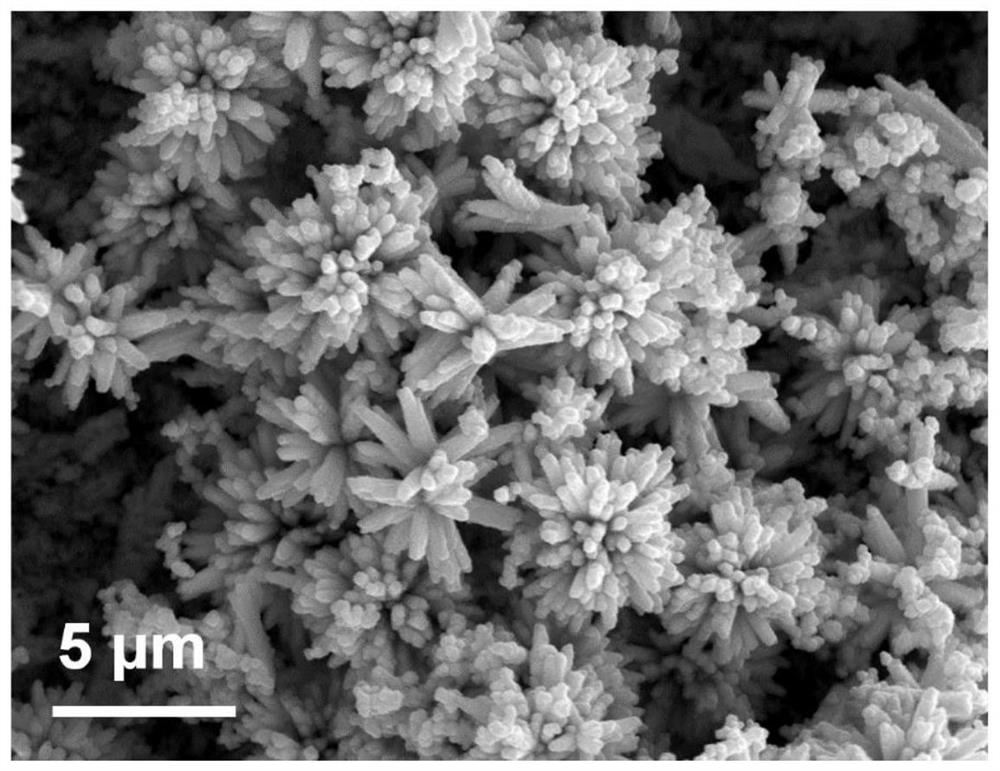

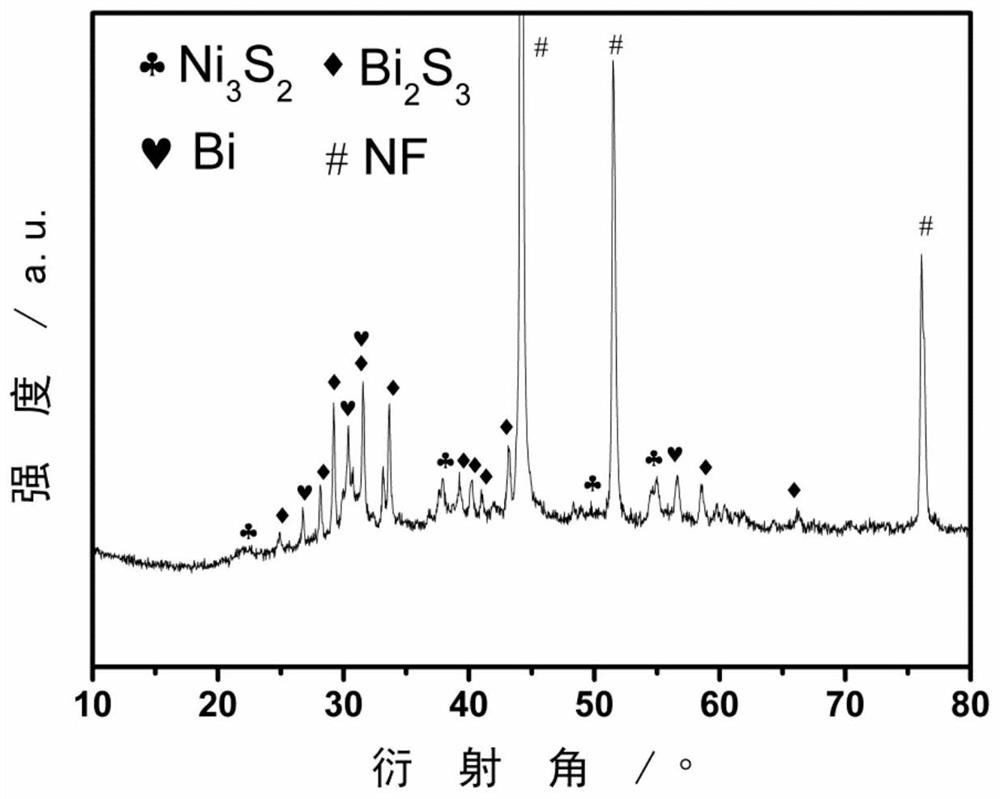

[0028] The cut metal Ni foam (2cm×4cm) was ultrasonically cleaned with 3M HCl, acetone, water, and ethanol for 10 min, and vacuum dried at 60° C. for 6 h before use. Weigh 1.0mmoL Bi (NO 3 ) 3 ·5H 2 O was dissolved in 40 mL of ethylene glycol to give solution A. Solution B was obtained by dissolving 1.5 mmol of thiourea in 20 mL of ethylene glycol solvent. Add solution B dropwise to solution A, stir well and mix well. The mixed solution was then transferred to the autoclave, and at the same time 1 piece of the above clean and dry metal Ni foam was taken and placed vertically into the sealed high temperature autoclave. Finally, the reaction kettle was put into an oven, and the reaction temperature was controlled to be 160° C. After solvothermal reaction for 16 h, the reaction kettle was taken out and cooled naturally. The product was repeatedly washed with deionized water and ethanol, and dried in a vacuum oven at 60 °C for 12 h to obtain Bi 2 S 3 / Ni 3 S 2 / NF heteroj...

Embodiment 2

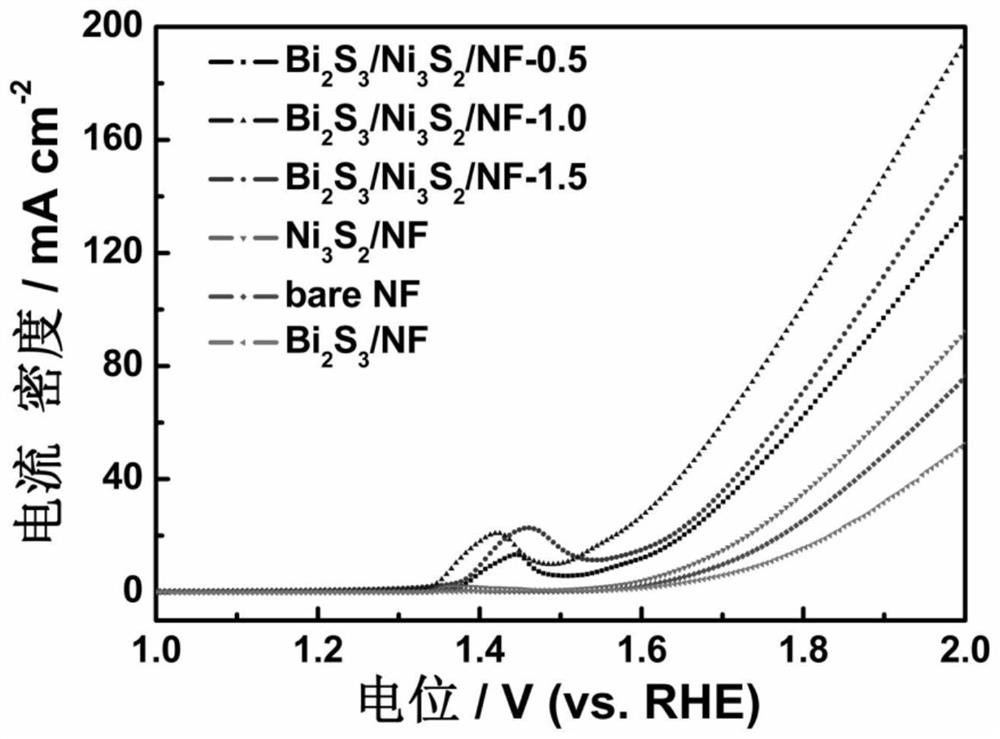

[0030] Example 2 is similar to Example 1, and the solvent in Example 2 is deionized water. Earned Bi 2 S 3 / Ni 3 S 2 / NF was used as the working electrode, and Hg / HgO and platinum sheets were used as the reference electrode and the counter electrode, respectively. Electrodes prepared in deionized water do not meet the requirements for flexible working electrodes.

Embodiment 3

[0032] Example 3 is similar to Example 1, and the solvent in Example 3 is ethanol. Earned Bi 2 S 3 / Ni 3 S 2 / NF was used as the working electrode, and Hg / HgO and platinum sheets were used as the reference electrode and the counter electrode, respectively. at 10mA cm -2 The reference current density of Bi prepared in ethanol 2 S 3 / Ni 3 S 2 / NF, only 310mV overpotential is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com