Preparation method and application of porous polymer containing iron and boron

A porous polymer, iron source technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve problems such as instability and achieve the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the porous polymer containing iron and boron in this embodiment is as follows:

[0036] (1) 0.3 mmol of boron-containing tetrahedral building block tetrakis (4-boronic acid phenyl), 1.2 mmol of ferrous chloride and 1.8 mmol of 2,6-diformyl-4-methylphenol di Oxime (synthetic schematic diagram see Figure 6 ) into 50mL of methanol solvent, stirring and dispersing evenly.

[0037] (2) Stir and disperse evenly and put it into a round bottom flask.

[0038] (3) The round-bottomed flask was refluxed and stirred at 65° C. for 48 hours, cooled to room temperature after the reaction, and the solid was collected by suction filtration.

[0039] (4) The collected solid was centrifuged and washed 10 mL×5 times with DMF and THF successively, and the solid was collected again.

[0040] (5) After Soxhlet extraction of the solid with THF for 24 hours, vacuum drying at 90° C. for 8 hours to obtain a black solid, which is the porous polymer containing iron and...

Embodiment 2

[0047] The preparation method of the porous polymer containing iron and boron in this embodiment is as follows:

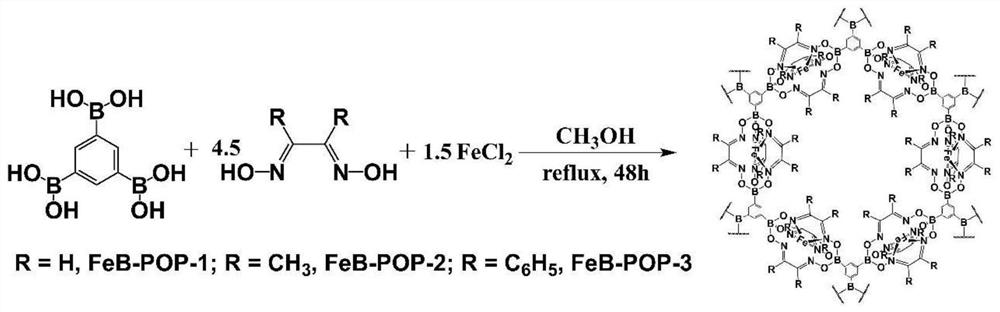

[0048] (1) 0.3mmol of benzene-1,3,5-triyltriboric acid, 0.45mmol of ferrous chloride and 1.35mmol of glyoxime (see figure 1 ) into 55mL of methanol solvent, stirring and dispersing evenly.

[0049] (2) Stir and disperse evenly and put it into a round bottom flask.

[0050] (3) The round-bottomed flask was refluxed and stirred at 60° C. for 42 hours, cooled to room temperature after the reaction, and the solid was collected by suction filtration.

[0051] (4) The collected solid was centrifuged and washed 10 mL×5 times with DMF and THF successively, and the solid was collected again.

[0052] (5) After Soxhlet extraction of the solid THF for 24 hours, vacuum drying at 90° C. for 8 hours to obtain a black solid, which is the porous polymer containing iron and boron, marked as FeB-POP-1.

[0053] The same method as in Example 1 was used to carry out the electrocataly...

Embodiment 3

[0055] The preparation method of the porous polymer containing iron and boron in this embodiment is as follows:

[0056] (1) 0.3mmol of benzene-1,3,5-triyltriboric acid, 0.45mmol of ferrous chloride and 1.35mmol of dimethylglyoxaloxime (synthetic schematic diagram see figure 1 ) into 50mL of methanol solvent, stirring and dispersing evenly.

[0057] (2) Stir and disperse evenly and put it into a round bottom flask.

[0058] (3) The round-bottomed flask was refluxed and stirred at 60° C. for 40 hours at a constant temperature. After the reaction was completed, it was cooled to room temperature and the solid was collected by suction filtration.

[0059] (4) The collected solid was centrifuged and washed 20 mL×6 times with DMF and THF successively, and the solid was collected again.

[0060] (5) After Soxhlet extraction of solid THF for 24 hours, vacuum drying at 85° C. for 24 hours to obtain a black powder, which is the porous polymer containing iron and boron, marked as FeB-P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com