An anti-clogging safety and economical atomizer

A safe, economical and anti-clogging technology, which is applied in the field of patented atomizers, can solve the problems of easy adhesion on the back of the operator, large changes in spray volume and spray width, and unsatisfactory atomization effect, so as to avoid personal injury , large spray width and stable atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

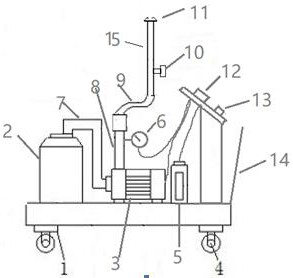

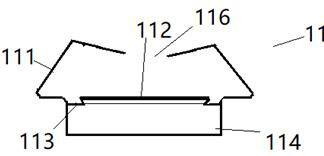

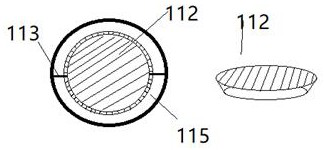

[0020] An anti-clogging, safe and energy-saving atomizer, including a pressurized atomizing nozzle 11, a constant pressure water supply system, a base 1, a universal wheel 4 and a handle 14; the boosted atomizing nozzle 11 includes a reflector 111 and a baffle 112 And the ring hole 115 (the radial length of the ring is 4mm), the baffle plate 112 is a circular pier shape and the area of the upper end surface (17mm in diameter) is greater than the area of the lower end surface (13mm in diameter); the baffle plate 112 and the booster atomizing nozzle 11 substrate There is an annular hole 115 in between, and the baffle 112 is fixedly connected with the substrate of the pressurized atomizing nozzle 11 through the cross bar 113; The liquid reflected to the upper surface of the baffle 112 (diameter 17mm); the center of the baffle 112 is a spray port 116, and the area of the spray port 116 (diameter 11mm) is smaller than the area of the upper surface of the baffle 112.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com