Flame-retardant epoxy resin based on iron-containing nickel silicate and preparation method of flame-retardant epoxy resin

A technology of epoxy resin and nickel silicate, which is applied in the field of halogen-free flame-retardant epoxy resin, can solve the problems of reduced bending strength and fracture strain, reduced other properties of the epoxy matrix, and failure to meet high flame-retardant requirements. Improvement of combustion effect, improvement of vertical combustion performance, and excellent smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The specific preparation method of the silicon source is: NH with a volume ratio of 1 to 4:80:30 3 ·H 2 O, C 2 h 5 OH and deionized water to form a solution, and slowly add silane compound and C with volume ratio of 1 to 4:80 under stirring 2 h 5 The mixed solution made of OH is continuously stirred for 6-12 hours to fully hydrolyze the silane compound, then the product is centrifuged, washed with ethanol and dried to obtain the silicon source.

[0033] The silane compound is one or more of TMOS, TEOS, KH550, KH560, KH570.

[0034] Nickel source is NiCl 2 , Ni(NO 3 ) 2 , Ni(CH 3 COO) 2 one or more of.

[0035] The preparation method of the flame-retardant epoxy resin based on iron-containing nickel silicate in the present invention comprises the following steps:

[0036] (1) Mix the silicon source and deionized water with a mass ratio of 0.02-0.09:20, and ultrasonicate to a uniform suspension to obtain a silicon source solution; mix the nickel source and NH w...

Embodiment 1

[0041] A preparation method based on iron-containing nickel silicate flame retardant epoxy resin, comprising the following steps:

[0042] (1) First mix 30mL deionized water, 80mL absolute ethanol and 2mL NH 3 ·H 2 O mixed and stirred, then slowly drop the mixture of 1mL TEOS, 1mL KH550 and 80mL absolute ethanol into the above alkaline solution, the dropping speed is as slow as possible. After stirring for 12 hours, the white turbid liquid was centrifuged, washed with ethanol, and dried in an oven at 80°C for 12 hours to obtain white SiO 2 microsphere powder.

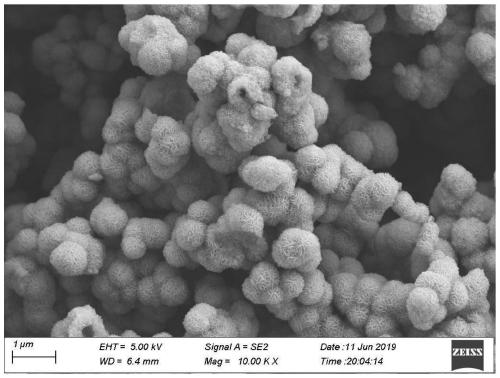

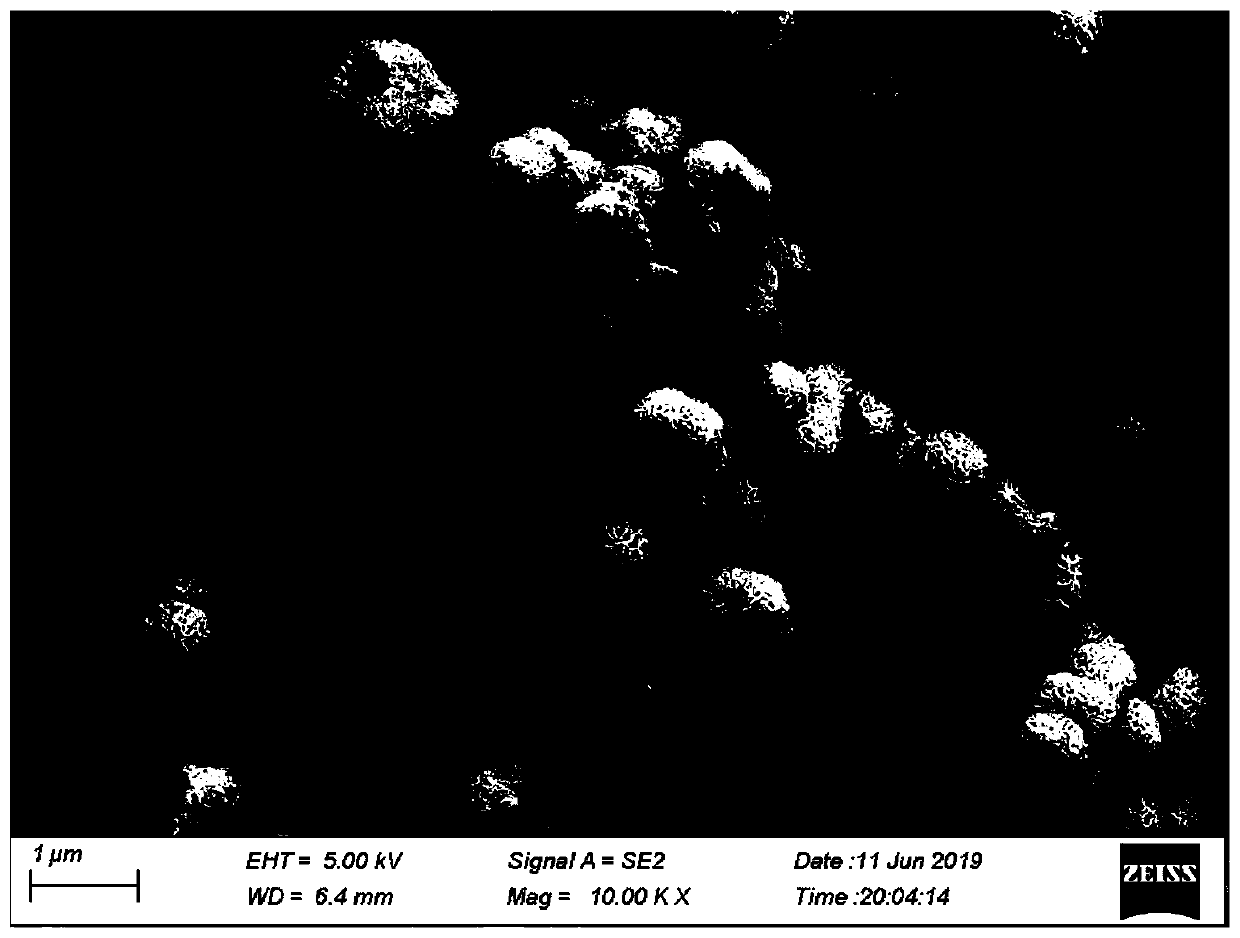

[0043] Then 0.05g SiO 2 Mix microsphere powder with 20mL deionized water and sonicate for 30 minutes to obtain SiO 2 solution; another 1mLNH 3 ·H 2 O, 30mL deionized water, 0.18g NiCl 2 ·6H 2 O, 0.53g NH 4 After Cl was made into a solution, it was mixed with SiO 2 The solutions were mixed and poured into a polytetrafluoroethylene-lined stainless steel reactor for hydrothermal reaction at a reaction temperature...

Embodiment 2

[0049] A preparation method based on iron-containing nickel silicate flame retardant epoxy resin, comprising the following steps:

[0050] Iron-containing nickel silicate was prepared according to the method described in Example 1. Stir 30g of E-51 epoxy resin in an oil bath at 70°C, and at the same time add 0.9g of iron-containing nickel silicate into 30mL of acetone, sonicate for 30 minutes and pour into E-51 epoxy resin, and continue stirring for 2 hours. In addition, 7.74g of 4,4'-diaminodiphenylmethane was melted at 100°C and added to the mixture of iron-containing nickel silicate and E-51, stirred vigorously for 5 minutes, then placed in a vacuum oven, and poured into the Put it into the mold, then put it into an oven to cure, cure at 100°C for 2 hours, and continue to cure at 150°C for 2 hours to obtain a halogen-free flame-retardant epoxy resin containing iron-nickel silicate.

[0051] According to the standard ASTM D 2863-2017a, a standard sample of 127mm×6.5mm×3.2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com