Hydrophobic flame retardant and preparation method thereof

A technology of flame retardants and intumescent flame retardants, applied in coatings, fireproof coatings, etc., can solve the problems of unsuitable for large-scale application, unsatisfactory hydrophobic effect of flame retardants, high cost, etc., and achieve low cost and simple preparation method , good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of hydrophobic flame retardant of the present invention comprises the following steps:

[0035] Disperse the flame retardant in the mixture of ethanol and water, stir and heat up to 30-50°C, adjust the pH value of the solution at 8-12, add modifier, react at this temperature for 1-3 hours, and then raise the temperature to 55-80°C, add modifier again, continue to react at this temperature for 1-3 hours, and finally cool to room temperature, filter with suction, wash, and dry to constant weight to obtain the hydrophobic flame retardant.

Embodiment 1

[0038] A preparation method of a hydrophobic flame retardant, comprising the following steps:

[0039] Disperse 50g of magnesium hydroxide in a mixture of 150ml of ethanol and 50ml of water, stir and heat up to 40°C, adjust the pH of the solution to 9, add 10g of tetraethyl orthosilicate, and react at this temperature for 2h; Raise the temperature to 55°C, add 2.5g of vinyltrimethoxysilane again, and continue the reaction at this temperature for 1 hour; finally cool to room temperature, filter with suction, wash, and dry to constant weight to obtain a hydrophobic flame retardant.

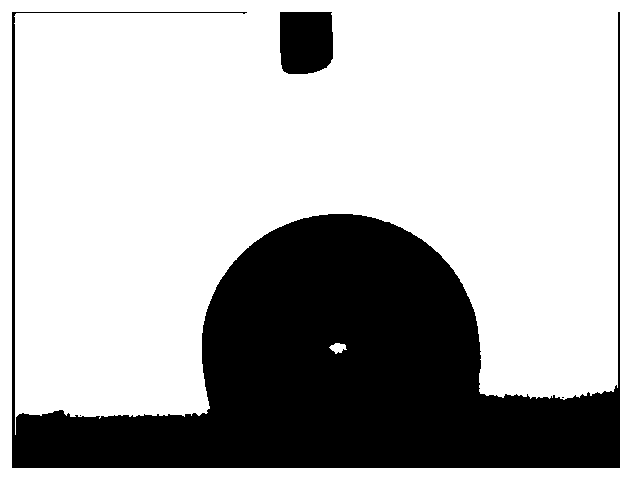

[0040] Hydrophobic test is carried out to the hydrophobic flame retardant in the present embodiment: the water contact angle of the hydrophobic flame retardant made by embodiment 1 is 138.16 ° (see figure 1 ).

Embodiment 2

[0042] A preparation method of a hydrophobic flame retardant, comprising the following steps:

[0043] Disperse 50g of magnesium hydroxide in a mixture of 150ml of ethanol and 50ml of water, stir and heat up to 40°C, adjust the pH of the solution to 9, add 10g of tetraethyl orthosilicate, and react at this temperature for 2h; Raise the temperature to 60°C, add 2g of dodecyltriethoxysilane again, and continue the reaction at this temperature for 1.5h; finally cool to room temperature, suction filter, wash, and dry to constant weight to obtain a Hydrophobic flame retardant.

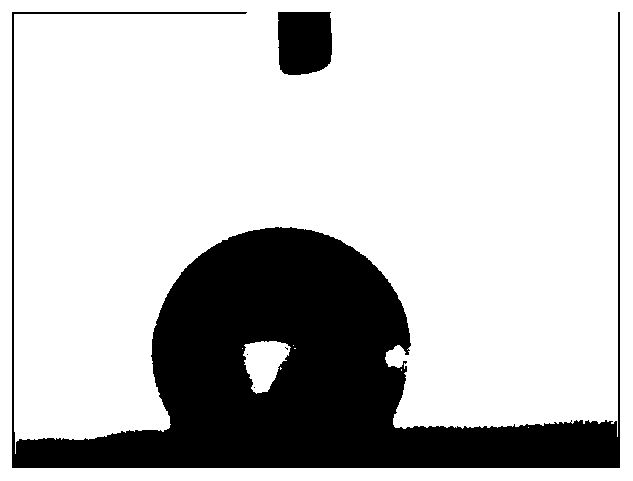

[0044] Hydrophobic test is carried out to the hydrophobic flame retardant in the present embodiment: the water contact angle of the hydrophobic flame retardant made by embodiment 2 is 134.58 ° (see figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com