Aluminum nitrate-containing nitric acid wastewater treatment system and treatment method thereof

A wastewater treatment system, aluminum nitrate technology, applied in multi-stage water treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc., can solve the problem that the final effect temperature should not be too low, the production risk is high, and evaporation The problem of large quantity and other problems, to achieve the effect of long-term stable operation, low production risk, and small evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

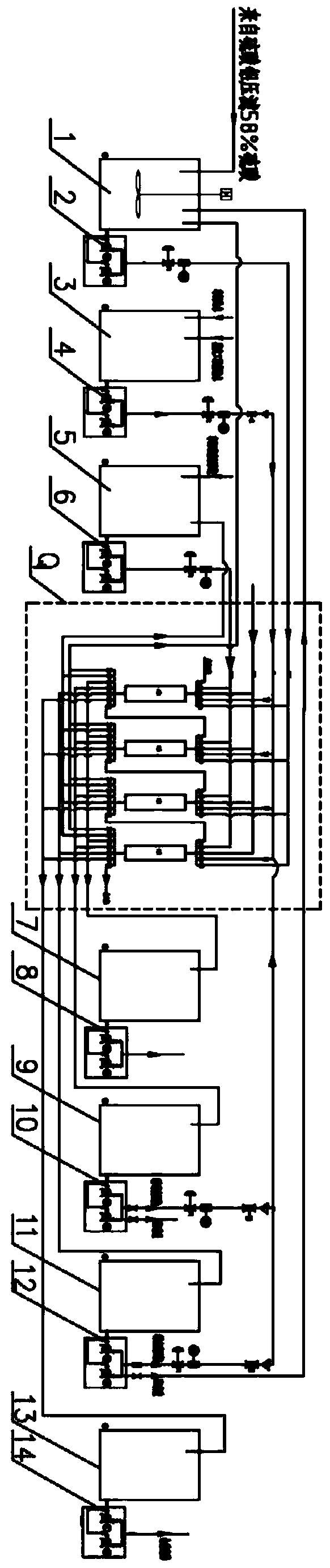

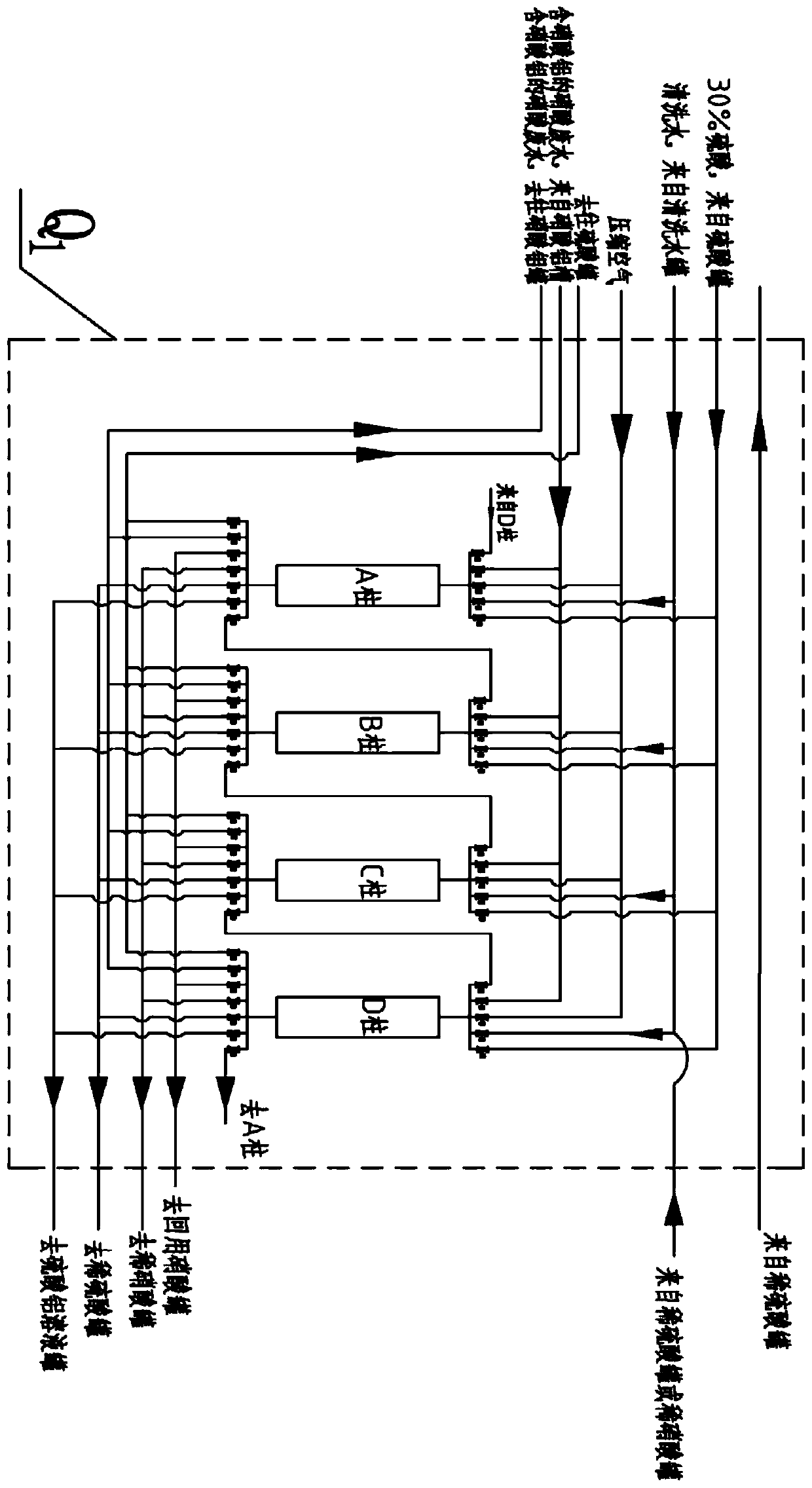

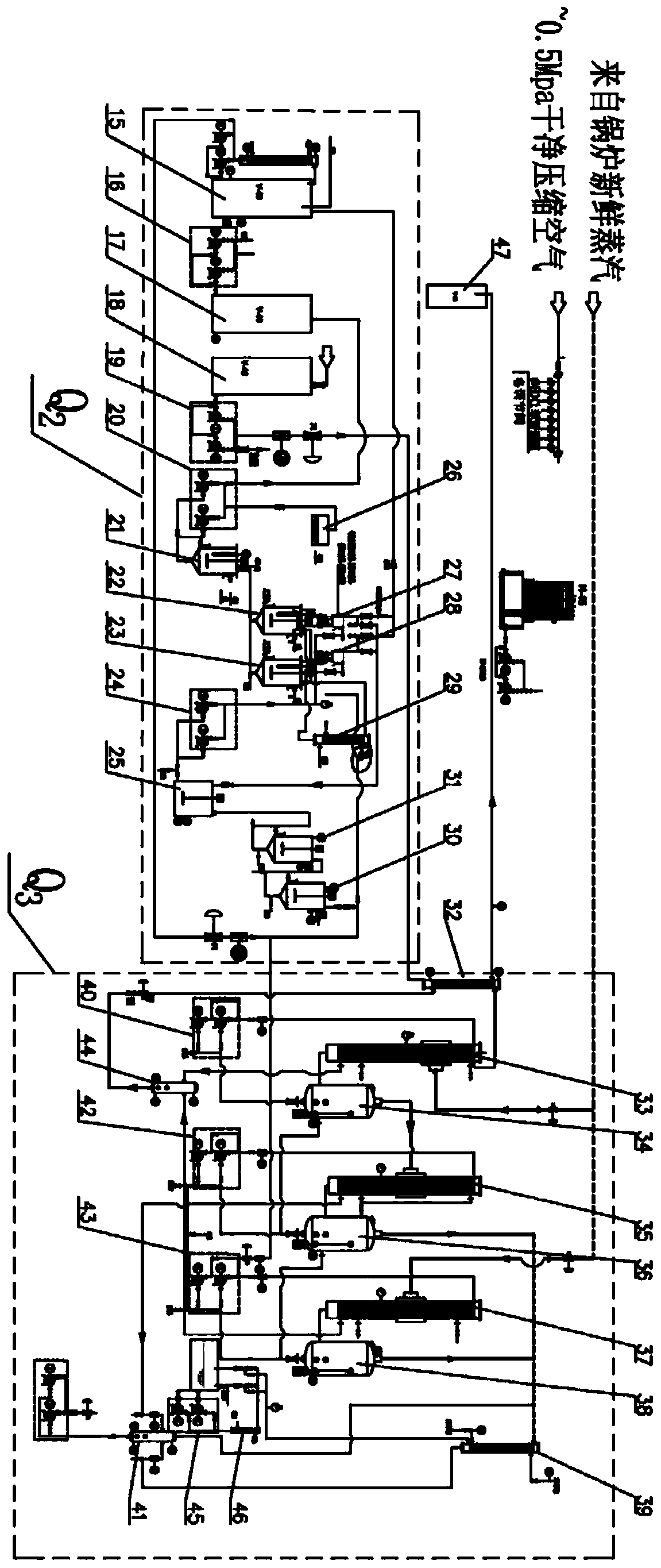

[0046] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the composition related to the present invention, and directions and references (for example, up, down, left, right, etc.) can only Used to aid in the description of features in a drawing. Accordingly, the following Detailed Description is not to be taken in a limiting sense, and the scope of claimed subject matter should be defined only by the appended claims and their equivalents.

[0047] In the description of the present invention, it should be noted that, unless otherwise clearly specified and limited, the terms "installation", "connection", "connection", "setting", and "installation" should be understood in a broad sense, for example, It can be a fixed connection, a detachable connection, or an integral conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com