A gnawing-assisted arc melting-brazing method for dissimilar metals

A brazing method and technology of dissimilar metals, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as the inability to solve the differences in the linear expansion coefficients of dissimilar metals, the inability to achieve mechanical engagement, and the inability to apply to ordinary structural parts, etc. , to achieve the effect of enhancing the mechanical interlocking effect of the interface, avoiding welding seam inclusions, and avoiding chemical residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

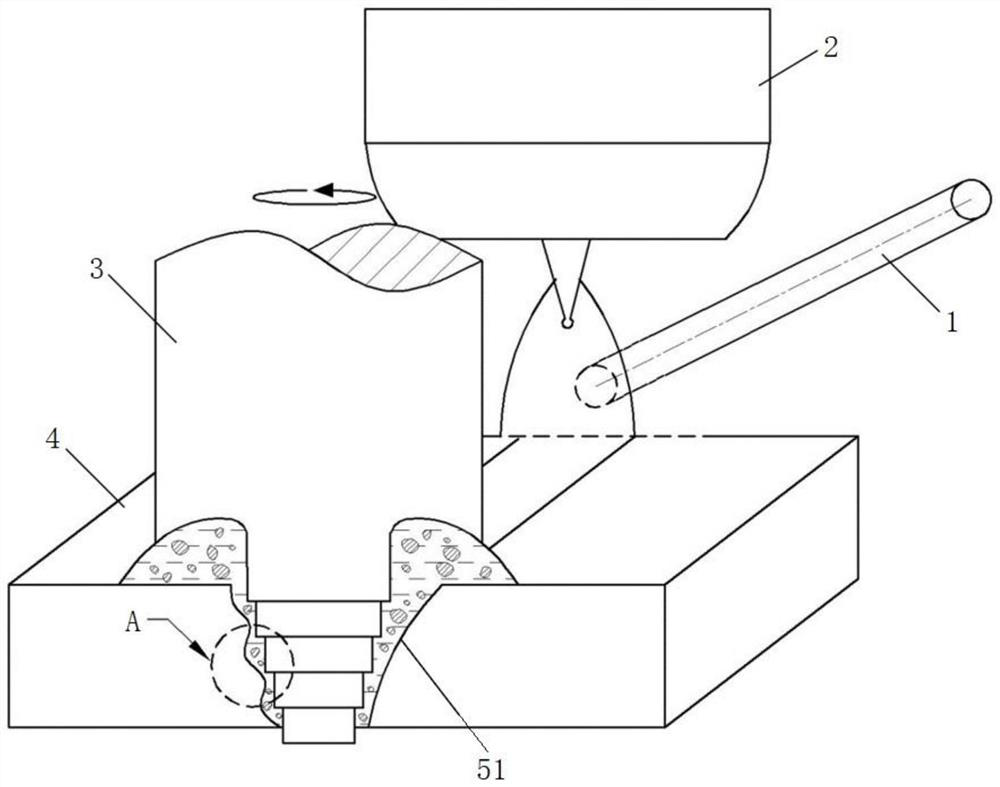

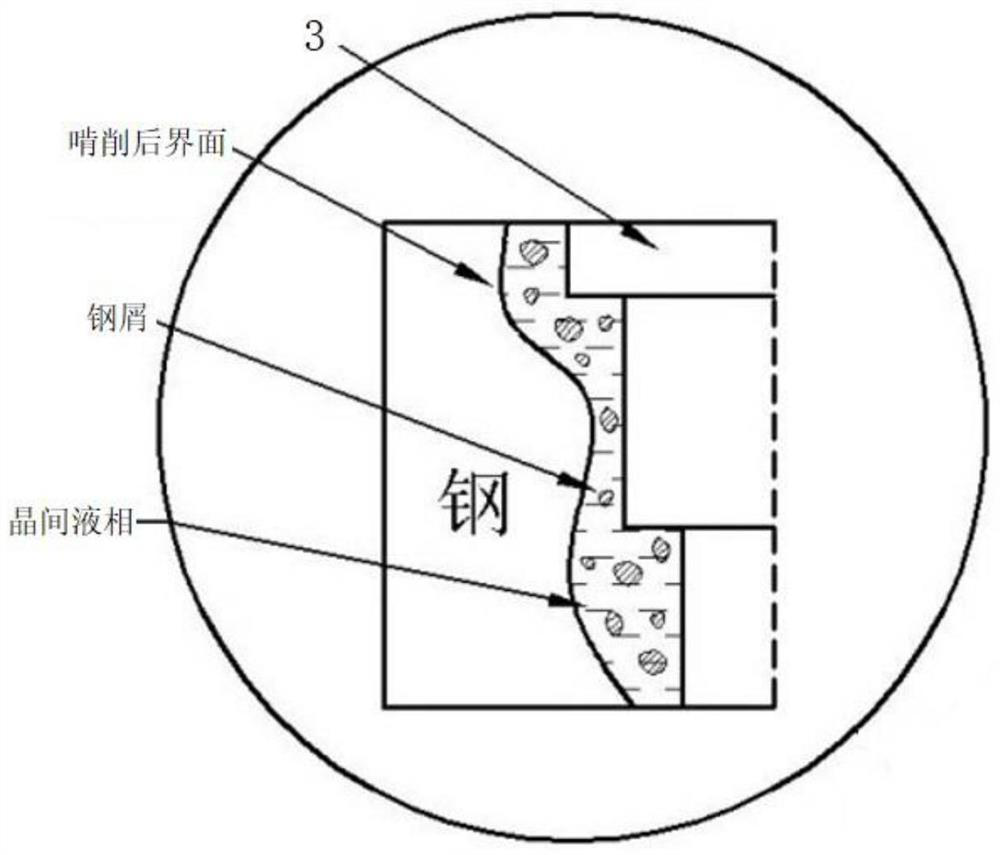

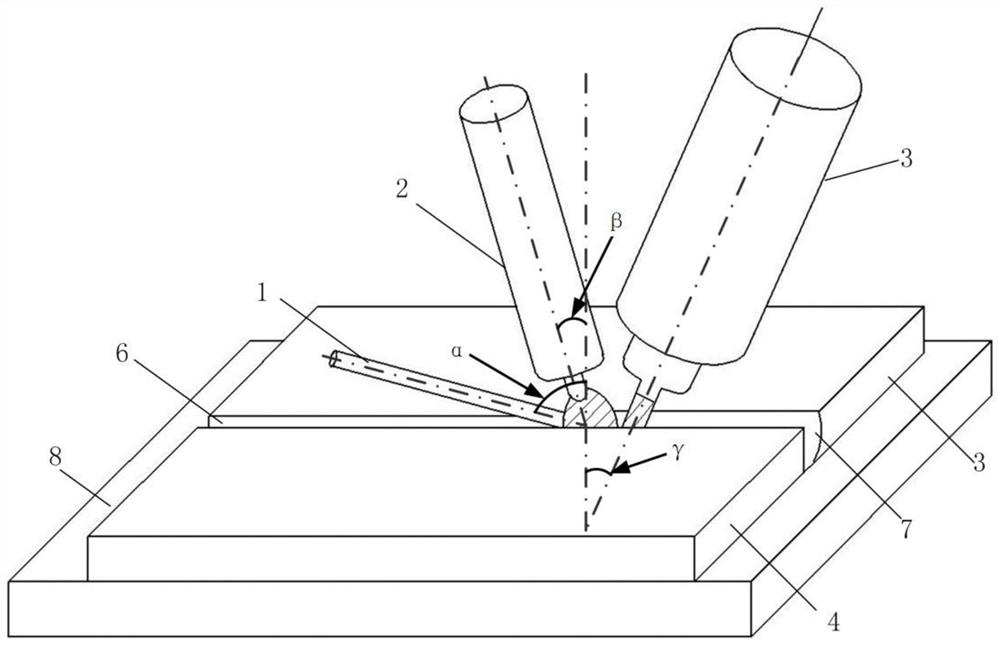

[0035] Embodiment 1, a gnawing-assisted dissimilar metal arc melting-brazing method, which includes the following steps.

[0036] Step one, see image 3 , the selected mixing head 3 includes a handle 31 and a nibbling part 32 connected with the handle 31, the nibbling part is provided with four steps from the 32 end to the direction of the handle, and the diameter of the plurality of steps is far away from the handle. 31 direction decreases, the unilateral taper of the nibbling portion 32 is 14°, the overall length of the nibbling portion 32 is 6mm, the tip diameter of the nibbling portion 32 is 2mm, and the root diameter of the nibbling portion 32 is 4mm. A bevel is processed on the surface to be welded of the steel plate 4, and the angle of the bevel is the same as the taper of the nibbling part 32. An avoidance bevel 51 is processed on the surface to be welded of the aluminum alloy plate 5, and then the steel plate is removed by mechanical grinding 4 and the oxide film on ...

Embodiment 2

[0042] Embodiment 2, a gnawing-assisted dissimilar metal arc melting-brazing method, which includes the following steps.

[0043] Step 1, the selected mixing head includes a shank and a nibbling part connected to the shank, the nibbling part is provided with four steps from the end to the direction of the shank, and the diameter of the multiple steps decreases from the direction away from the shank , the unilateral taper of the nibbling part is 14°, the overall length of the nibbling part is 6.8 mm, the diameter of the tip of the nibbling part is 2 mm, and the root diameter of the nibbling part is 4 mm. A groove is processed on the surface to be welded of the steel plate, and the angle of the groove is the same as the taper of the nibbling part, and an avoidance groove is processed on the surface to be welded of the aluminum alloy plate, and then the steel plate and the aluminum alloy plate are removed by mechanical grinding surface oxide film, and clean the surface of the ste...

Embodiment 3

[0048] Embodiment 3, a gnawing-assisted dissimilar metal arc melting-brazing method, which includes the following steps.

[0049] Step 1, the selected mixing head includes a shank and a nibbling part connected to the shank, the nibbling part is provided with four steps from the end to the direction of the shank, and the diameter of the multiple steps decreases from the direction away from the shank , the unilateral taper of the nibbling part is 14°, the overall length of the nibbling part is 5.5 mm, the diameter of the tip of the nibbling part is 2 mm, and the root diameter of the nibbling part is 4 mm. A groove is processed on the surface to be welded of the steel plate, and the angle of the groove is the same as the taper of the nibbling part, and an avoidance groove is processed on the surface to be welded of the aluminum alloy plate, and then the steel plate and the aluminum alloy plate are removed by mechanical grinding surface oxide film, and clean the surface of the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com