Temperature-sensitive gel, temperature-sensitive sensor, preparation method of gel, and preparation method of sensor

A temperature-sensitive sensor and temperature-sensitive gel technology, which is applied in the direction of instruments, thermometers, scientific instruments, etc., can solve the problems of unfavorable large-scale production, poor biocompatibility, and poor sensitivity, so as to shorten the preparation cycle and make the preparation process fast and convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Specifically, the preparation method includes the following steps:

[0029] S1: Dispersing the liquid metal, the first monomer, the crosslinking agent, and the initiator in the medium to prepare a mixed solution; and

[0030] S2: Forming the mixed solution on a carrier to form a preform, and performing a first curing treatment on the preform to obtain the temperature-sensitive gel.

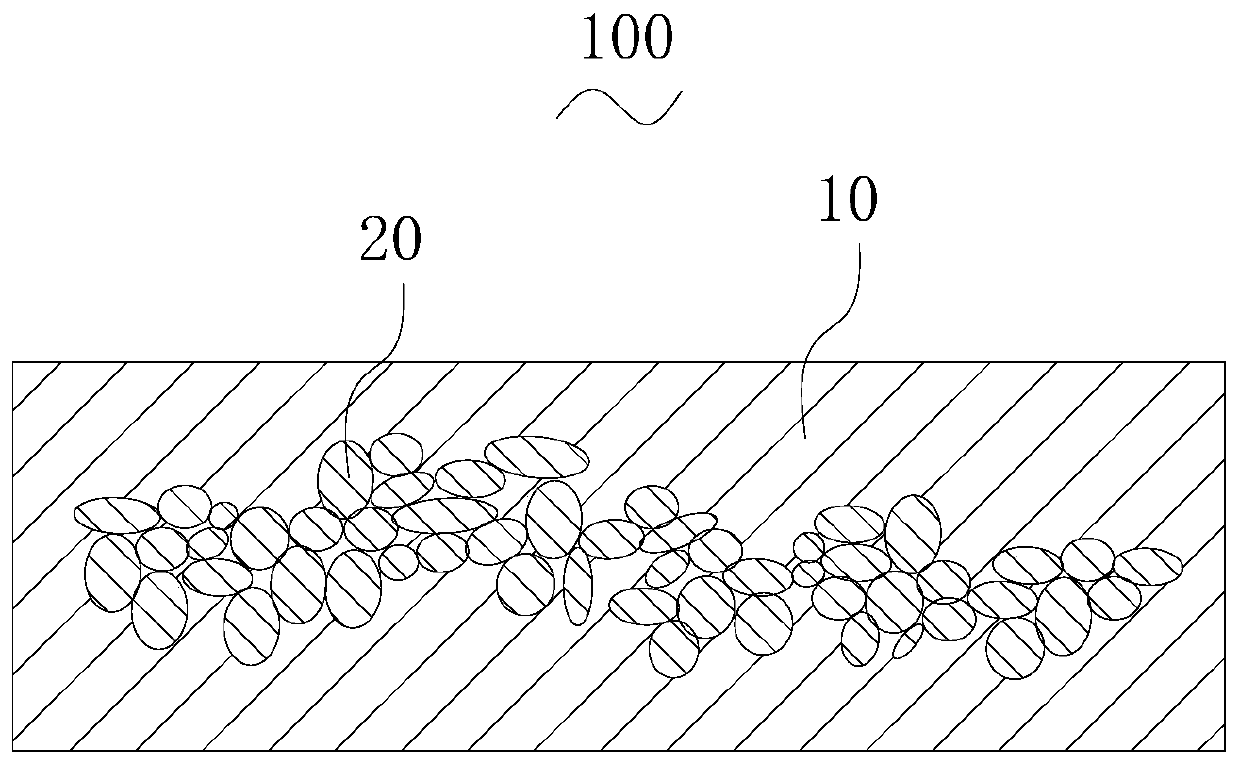

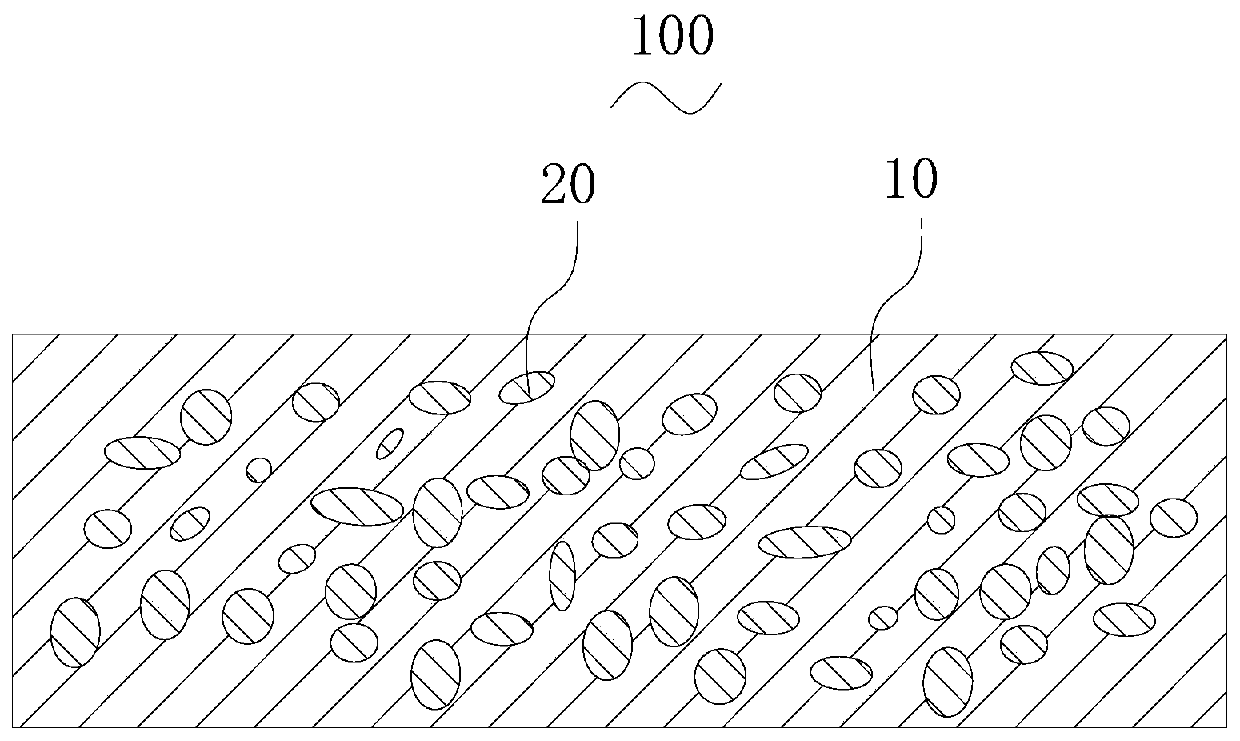

[0031] Wherein, the temperature-sensitive gel includes a first polymer, the first polymer is a temperature-sensitive polymer material obtained by polymerization of the first monomer, and the critical phase transition temperature of the first polymer is T 1 , and the first polymer has a three-dimensional network structure, the liquid metal and the medium are dispersed in the three-dimensional network structure; the temperature-sensitive gel can respond to changes in external temperature, and when the external temperature reaches a preset temperature T 2 , the liquid metal dispersed in the ...

Embodiment 1

[0079] (1) Add 15 parts by weight of gallium-indium alloy to 25 parts by weight of deionized water and ultrasonically disperse for 8 minutes under an ultrasonic power of 60W to prepare solution A;

[0080] 20 parts by weight of N-isopropylacrylamide, 1.5 parts by weight of polyvinyl alcohol (molecular weight of 7000), 1 part by weight of N,N'-methylenebisacrylamide, 0.08 parts of tetramethylethylenedi The amine is dispersed in 30 parts by weight of deionized water to prepare solution B;

[0081] The ammonium persulfate (thermal initiator) of 0.6 weight part is dispersed in the deionized water of 6.82 weight part, makes solution C;

[0082] The prepared solution A, solution B and solution C were uniformly mixed and placed in a mold, and heated at a temperature of 50° C. for 10 minutes to obtain a temperature-sensitive gel.

[0083] (2) Paste the prepared thermosensitive gel on the polydimethylsiloxane substrate;

[0084] The conductive paste containing silver nanoparticles is...

Embodiment 2

[0088] (1) Add 8 parts by weight of gallium-tin-indium alloy into 30 parts by weight of deionized water and ultrasonically disperse for 2 minutes under an ultrasonic power of 100W to prepare solution A;

[0089] Disperse 18 parts by weight of N-isopropylacrylamide, 0.9 parts by weight of polyethylene glycol (molecular weight is 10000), 2 parts by weight of polyethylene glycol diacrylate, and 0.09 parts of tetramethylethylenediamine in In 47 parts by weight of deionized water, solution B was prepared;

[0090] Disperse 0.8 parts by weight of 1,3-acetone dicarboxylic acid (photoinitiator) in 3.21 parts by weight of deionized water to prepare solution C;

[0091] The prepared solution A, solution B and solution C were uniformly mixed and placed in a mold, and irradiated for 5s under the light of 400nm band, and the light intensity was 50mW / cm 2 , to prepare a thermosensitive gel.

[0092] (2) Paste the prepared thermosensitive gel on the thermoplastic polyurethane substrate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com