Light-screening transparent PVC material and preparation method thereof

A technology of PVC material and PVC resin, applied in the field of light-shielding transparent PVC material and its preparation, can solve the problems of low visible light transmittance, change of drug ingredients, cumbersome preparation process, etc., and achieve improved light-shielding wavelength range and high safety , Improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

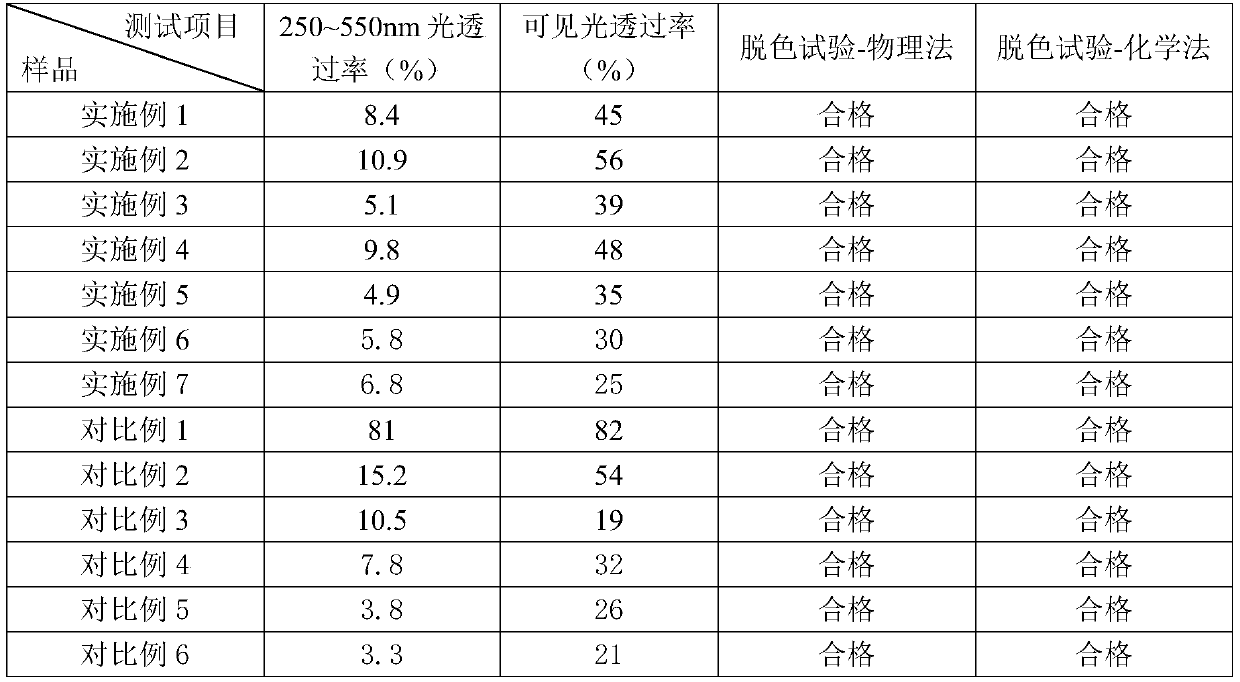

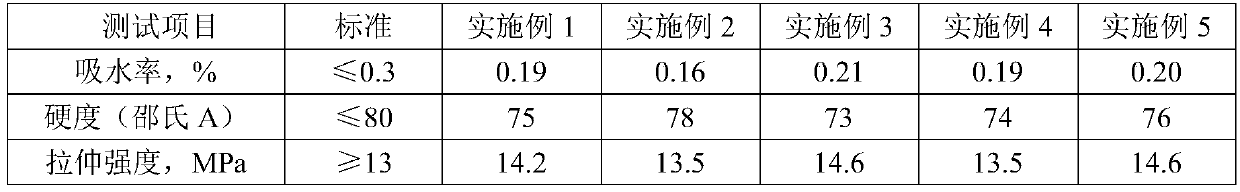

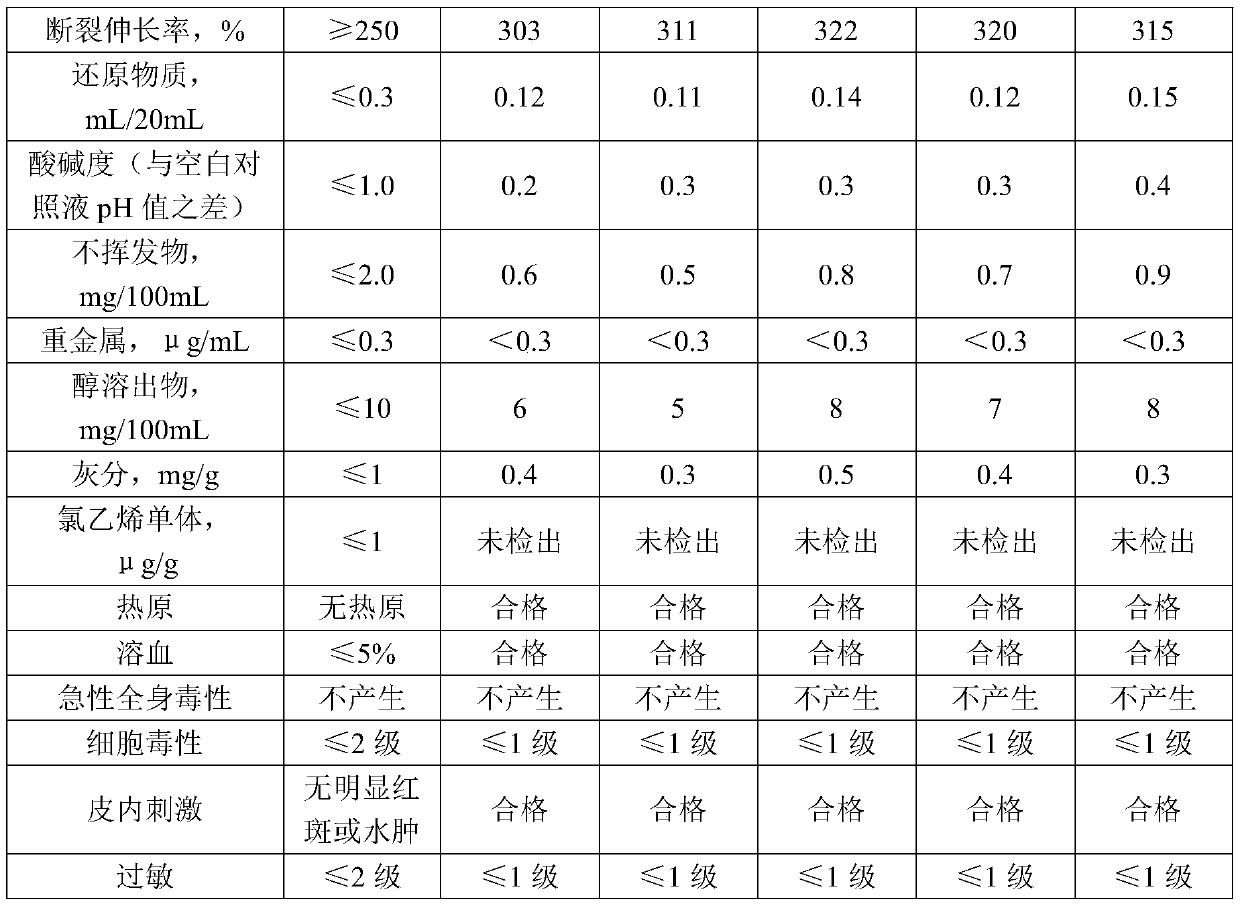

Examples

Embodiment 1

[0033] A light-shielding transparent PVC material, which is composed of the following components: 10kg of suspension polyvinyl chloride resin (polymerization degree: 800-2500), 6kg of TOTM, 0.15kg of calcium / zinc heat stabilizer (calcium ricinoleate 0.06kg, Zinc octoate 0.03kg, zinc stearate 0.03kg, polyvinyl alcohol 0.03kg), epoxy soybean oil 0.8kg, polyethylene wax 0.08kg, light-shielding agent 0.003kg (nano-zinc oxide 0.0024kg and nano-carbon black 0.0006kg) (Nano zinc oxide 80%, nano carbon black 20%).

[0034] (1) Add the four components of calcium ricinoleate, zinc octylate, zinc stearate and polyvinyl alcohol into the epoxy soybean oil liquid according to the stated ratio, stir at 155-165°C, and the stirring speed is 60- 80 rpm, the time is not less than 15 minutes, after observing that the solid particles are fully dispersed, pour them into the colloid grinder for circular grinding, control the diameter of the solid particles to be less than 1 μm, and use the colloid a...

Embodiment 2

[0038] A light-shielding transparent PVC material, which is composed of the following components: 10kg of suspension polyvinyl chloride resin (polymerization degree: 800-2500), 6kg of TOTM, 0.15kg of calcium / zinc heat stabilizer (calcium ricinoleate 0.06kg, Zinc octoate 0.03kg, zinc stearate 0.03kg, polyvinyl alcohol 0.03kg), epoxy soybean oil 0.8kg, polyethylene wax 0.08kg, light-shielding agent 0.001kg (nano-zinc oxide 0.0008kg and nano-carbon black 0.0002kg) (Nano zinc oxide 80%, nano carbon black 20%).

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0041] A light-shielding transparent PVC material, which is composed of the following components: 10kg of suspension polyvinyl chloride resin (polymerization degree: 800-2500), 8kg of TOTM, 0.15kg of calcium / zinc heat stabilizer (0.06kg of calcium ricinoleate, Zinc octoate 0.03kg, zinc stearate 0.03kg, polyvinyl alcohol 0.03kg), epoxy soybean oil 0.8kg, polyethylene wax 0.08kg, light-shielding agent 0.005kg (nano-zinc oxide 0.004kg and nano-carbon black 0.001kg) (Nano zinc oxide 80%, nano carbon black 20%).

[0042] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com