Preparation method of antistatic PVC composite material

A composite material, antistatic technology, applied in chemical instruments and methods, carbon compounds, calcium/strontium/barium compounds, etc., can solve the problems of graphene agglomeration and dust flying, avoid powder flying, overcome graphene agglomeration , The effect of solving interface compatibility and interaction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

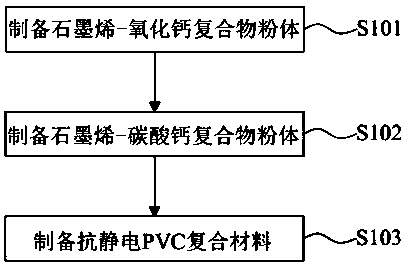

[0034] The present invention proposes a preparation method of an antistatic PVC composite material. The first embodiment describes in detail the preparation method of the antistatic PVC composite material proposed by the present invention with a specific example. The preparation method specifically includes:

[0035] (1) Preparation of graphene-calcium oxide composite powder

[0036] Transport the calcium hydroxide powder with a particle size of 300 mesh to the first tubular resistance furnace at 10kg / min, and pass nitrogen gas as the first carrier gas under the condition of 600°C for high-temperature activation treatment, and the nitrogen flow rate is 70 m 3 / h, the activation time is 90min. The catalyst after high-temperature activation is heated to 400° C. under the condition of isolation of oxygen, dispersed to make powder, and passed through acrylic acid for high-temperature modification to obtain the modified catalyst required for graphene growth. Transport the modifie...

Embodiment 2

[0045] The invention proposes a method for preparing an antistatic PVC composite material. On the basis of this, the invention can also derive a method for preparing three-dimensional graphene powder. The preparation method of the three-dimensional graphene powder that the second embodiment of the present invention proposes comprises the following steps:

[0046] (1) Preparation of graphene-calcium oxide composite powder

[0047] Transport the calcium hydroxide powder with a particle size of 325 mesh to the first tubular resistance furnace at 15kg / min, and pass nitrogen gas as the first carrier gas under the condition of 500°C for high-temperature activation treatment, and the nitrogen flow rate is 100 m 3 / h, the activation time is 120min. The catalyst after high-temperature activation is heated to 500° C. under the condition of isolation of oxygen, dispersed to make powder, and passed through stearic acid for high-temperature modification to obtain the modified catalyst re...

Embodiment 3

[0051] The PVC composite material in the prior art is often affected by external impact force. If the impact resistance of PVC pipes is poor, the service life of PVC pipes will be greatly shortened. In order to solve this technical problem, the present invention proposes a preparation method of an antistatic PVC composite material, so that it has good impact resistance on the basis of antistatic effect. The preparation method of the antistatic and impact-resistant PVC composite material that the third embodiment of the present invention proposes comprises the following steps:

[0052] (1) Preparation of graphene-calcium oxide composite powder

[0053] Transport the calcium hydroxide powder with a particle size of 400 mesh to the first tubular resistance furnace at 12kg / min, and pass nitrogen gas as the first carrier gas under the condition of 800°C for high-temperature activation treatment, and the nitrogen flow rate is 50 m 3 / h, the activation time is 60min. The catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com