Long-fiber reinforced polypropylene composite material capable of improving floating fiber and with high surface smoothness and preparation method for long-fiber reinforced polypropylene composite material

A composite material, polypropylene technology, applied in the field of polypropylene, can solve the problems of conventional performance influence, unfavorable floating fiber improvement, etc., to achieve the effect of improving the floating fiber of final parts, low preparation cost, and suitable for commercial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

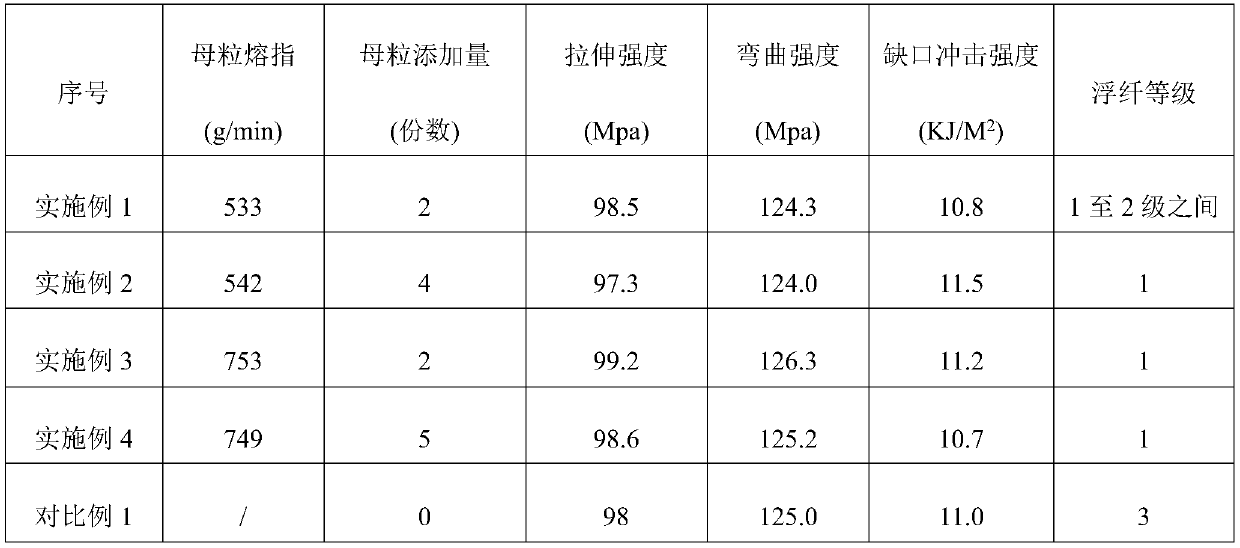

Examples

Embodiment 1

[0043] (1) Preparation of improved floating fiber, high surface finish functional masterbatch:

[0044] In parts by weight, the high flow rate polypropylene with a flow rate of 60g / min: 81 parts of BX3900; lubricant: 15 parts of vinyl polysiloxane; melt index regulator: F40 0.5 parts, antioxidant: 1010 0.5 parts; other additives: UV700 light stabilizer, carbon black, etc. 3 parts, etc.; add them to the high-speed mixer and mix evenly, then add them to the twin-screw extruder, It is melted, extruded, cooled, and pelletized by a twin-screw extruder to prepare a functional masterbatch with high fluidity, precipitation resistance, and scratch resistance. At 230°C and 2.16Kg, the flow rate of the masterbatch was measured to be 533g / min.

[0045] The processing setting temperatures of zones I to X of the twin-screw extruder are 100°C, 185°C, 190°C, 190°C, 195°C, 195°C, 195°C, 200°C, 200°C, and 200°C in sequence. The rotational speed of the main screw is 350r / min, and the temperat...

Embodiment 2

[0050] (1) Preparation of improved floating fiber, high surface finish functional masterbatch:

[0051] In parts by weight, the high flow rate polypropylene with a flow rate of 60g / min: 81 parts of BX3900; lubricant: 15 parts of vinyl polysiloxane; melt index regulator: F40 0.5 parts, antioxidant: 1010 0.5 parts; other additives: UV700 light stabilizer, carbon black, etc. 3 parts, etc.; add them to the high-speed mixer and mix evenly, then add them to the twin-screw extruder, It is melted, extruded, cooled, and pelletized by a twin-screw extruder to prepare a functional masterbatch with high fluidity, precipitation resistance, and scratch resistance. At 230°C and 2.16Kg, the flow rate of the masterbatch was measured to be 542g / min.

[0052] The processing setting temperatures of zones I to X of the twin-screw extruder are 100°C, 185°C, 190°C, 190°C, 195°C, 195°C, 195°C, 200°C, 200°C, and 200°C in sequence. The rotational speed of the main screw is 350r / min, and the temperat...

Embodiment 3

[0057] (1) Preparation of improved floating fiber, high surface finish functional masterbatch:

[0058] In parts by weight, high flow rate polypropylene with a flow rate of 60g / min: 53.5 parts of BX3900; lubricant: 40 parts of vinyl polysiloxane; melt index regulator: organic peroxide 2 parts of F40, antioxidant: 1010 0.5 parts; other additives: UV700 light stabilizer, 4 parts of carbon black, etc.; add them to the high-speed mixer and mix them evenly, then add them to the twin-screw extruder, It is melted, extruded, cooled, and pelletized by a twin-screw extruder to prepare a functional masterbatch with high fluidity, precipitation resistance, and scratch resistance. At 230°C and 2.16Kg, the flow rate of the masterbatch was measured to be 753g / min.

[0059] The processing setting temperatures of zones I to X of the twin-screw extruder are 100°C, 185°C, 190°C, 190°C, 195°C, 195°C, 195°C, 200°C, 200°C, and 200°C in sequence. The rotational speed of the main screw is 300r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com