1,2,4-triazole nitrate-coated boron-magnesium composite metal powder fuel and preparation method thereof

A composite metal and nitrate technology, which is used in explosive composite components, offensive equipment, explosive processing equipment, etc., can solve the problems of high calorific value, high oxygen consumption of boron, and more residues, etc., to improve combustion efficiency, increase The effect of improving combustion temperature and heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation process of 1,2,4-triazole nitrate is as follows: in a nitrogen-filled drying oven, add 1.0458g, 15.1mmol of 1,2,4-triazole to a Schlenk flask, under nitrogen flow, under stirring conditions Add 13ml of anhydrous methanol, then carefully add 1.3925g, 15.2mmol of concentrated nitric acid, react at room temperature for 1h, transfer to a vacuum drying oven after the reaction is completed, and dry at room temperature for 24h, the white crystal product is the prepared 1,2,4-triazole nitrates.

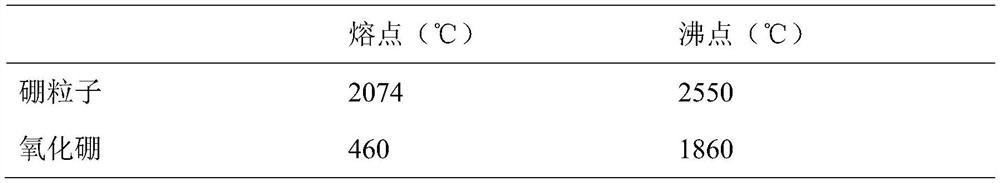

[0036] In order to test the application performance of the boron-magnesium composite metal powder fuel coated with the energetic ion salt 1,2,4-triazole nitrate of this patent, the physical and chemical properties of the fuel were firstly characterized, and secondly, the fuel particles were added to the boron-rich Fuel propellants and boron-based ignition powders are prepared to test their combustion properties.

[0037] The boron-containing fuel-rich propellant formul...

Embodiment 1

[0044] Taking the target product quality of 100g as an example, the amount and type of various raw materials required are: boron-magnesium composite metal powder (particle size 4.5 μm, boron content 93%) 78g, 1,2,4-triazole nitrate (purity 99 %) 21.2g, silane coupling agent KH5600.8g, methanol 1060ml. Accurately weigh quantitative 1,2,4-triazole nitric acid and KH560, dissolve in methanol, add boron-magnesium composite metal powder to the above solution under room temperature stirring conditions, fully stir, and evenly disperse to form a mixed suspension; The mixed suspension was evacuated in a four-neck flask under stirring at 45° C. until the surface was dry and semi-slurry. Take it out and move it to a vacuum oven for drying at 50°C until the boron-magnesium composite metal powder is in a relatively dry state. The above-mentioned boron-magnesium composite metal powder is sieved, classified and screened to form boron-magnesium composite metal powder fuel coated with energet...

Embodiment 2

[0046]Taking the target product quality of 100g as an example, the amount and type of various raw materials required are: boron-magnesium composite metal powder (particle size 4.5 μm, boron content 95%) 78g, 1,2,4-triazole nitrate (purity 99 %) 21.2g, silane coupling agent KH5600.8g, methanol 1060ml. Accurately weigh quantitative 1,2,4-triazole nitric acid and KH560, dissolve in methanol, add boron-magnesium composite metal powder to the above solution under room temperature stirring conditions, fully stir, and evenly disperse to form a mixed suspension; The mixed suspension was evacuated in a four-neck flask under stirring at 45° C. until the surface was dry and semi-slurry. Take it out and move it to a vacuum oven for drying at 50°C until the boron-magnesium composite metal powder is in a relatively dry state. The above-mentioned boron-magnesium composite metal powder is sieved, classified and screened to form boron-magnesium composite metal powder fuel coated with energeti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com