A kind of facing layer material, photovoltaic building material and preparation method thereof

A facing layer and building material technology, applied in the direction of photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of glaze being difficult to apply to photovoltaic modules, poor chemical stability, and reduced service life, etc., to achieve strong adhesion , good weather resistance, good power generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

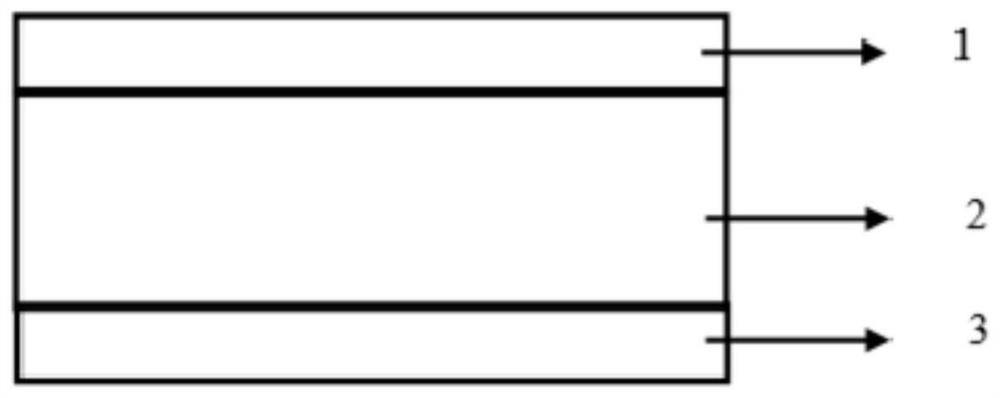

Image

Examples

Embodiment 1

[0037] Prepare a decorative layer on the prepared solar cell layer, and the specific steps include:

[0038] Preparation of slurry, its components and weight ratio include: 2.5 parts of inorganic pigment, 20 parts of silica sol, 12 parts of spinel powder, 20 parts of kaolin powder, 20 parts of red garnet powder, 8 parts of talc powder, 3 parts of lime powder and 35 parts of water.

[0039] The selected pigment is an inorganic pigment, and the selected one is a mixture of iron oxide red and iron oxide yellow.

[0040] The silicon dioxide content in the silica sol is 30%.

[0041] Spinel powder, kaolin powder, red garnet powder, and lime powder are powders with a mesh size of 1800 or more.

[0042] Spinel powder, kaolin powder, red garnet powder, and lime powder are commercially available products.

[0043] The above-mentioned raw materials are mixed according to their respective weight parts, dispersed and stirred at a high speed, and the finished product is obtained by spra...

Embodiment 2

[0047] Prepare a decorative layer on the prepared solar cell layer, and the specific steps include:

[0048] Preparation of slurry, its components and weight ratio include: 3.6 parts of inorganic pigment, 40 parts of silica sol, 15 parts of spinel powder, 20 parts of kaolin powder, 20 parts of red garnet powder, 3 parts of talc powder, 8 parts of lime powder and 15 parts of water.

[0049] The selected pigments are natural inorganic pigments, which are a mixture of stone green and realgar.

[0050] Silica sol has a silica content of 36%.

[0051] Spinel powder, kaolin powder, red garnet powder, lime powder are more than 2000 mesh powder.

[0052] Spinel powder, kaolin powder, red garnet powder, and lime powder are commercially available products.

[0053] The above-mentioned raw materials are mixed according to their respective weight parts, dispersed and stirred at a high speed, and the finished product is obtained by spraying.

[0054] The curing temperature of the facin...

Embodiment 3

[0057] Prepare a decorative layer on the prepared solar cell layer, and the specific steps include:

[0058] Preparation of slurry, its components and weight ratio include: 6 parts of inorganic pigment, 25 parts of silica sol, 20 parts of spinel powder, 18 parts of kaolin powder, 28 parts of red garnet powder, 5 parts of talc powder, 3 parts of lime powder and 30 parts of water.

[0059] The selected pigment is an inorganic pigment, and the selected one is a mixture of carbon black and realgar.

[0060] The silicon dioxide content in the silica sol is 25%.

[0061] Spinel powder, kaolin powder, red garnet powder, and lime powder are powders with a mesh size of 1700 or more.

[0062] Spinel powder, kaolin powder, red garnet powder, and lime powder are commercially available products.

[0063] The above-mentioned raw materials are mixed according to their respective weight parts, dispersed and stirred at a high speed, and the finished product is obtained by spraying.

[0064] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com