Light-guide concrete-based photovoltaic solar structure unit and pavement construction method

A photovoltaic solar energy and structural unit technology, applied in the field of photovoltaic solar energy, can solve the problems of high cost, uneconomical cost, and small friction coefficient of plexiglass materials, etc., and achieve the effects of strong mechanical properties, broad application prospects, and good power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

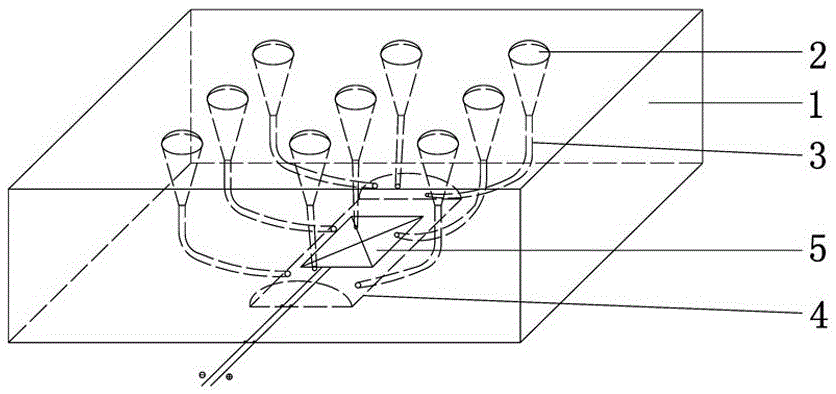

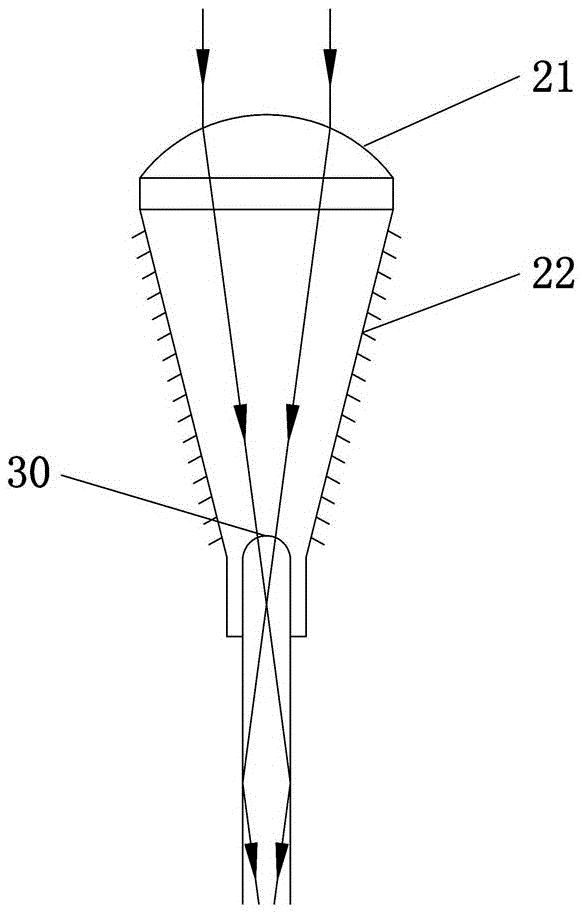

[0039] Figure 1 to Figure 4 It shows an embodiment of a photovoltaic solar structural unit based on light-guiding concrete of the present invention, which includes a concrete base 1, a light-collecting part 2, an optical fiber 3, a protective cover 4 and a photovoltaic solar panel 5, and the protective cover 4 is located on the concrete A closed cavity for placing photovoltaic solar panels 5 is formed between the bottom of the base 1 and the concrete base 1. The concentrating part 2 is located on the top of the concrete base 1. One end of the optical fiber 3 is connected to the concentrating part 2, and the other end passes through the protective cover 4 and point to the photovoltaic solar panel 5 . In the photovoltaic solar structural unit based on light-guiding concrete of the present invention, its concentrating part 2, optical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com