Automatic online film pasting machine for profiles

A film laminating machine and automatic technology, applied in packaging and other directions, can solve problems such as easy to wrinkle, easy to peel, increase labor, site and equipment costs, etc., to achieve the effect of reducing position error, convenient and fast switching, and fast and convenient switching methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

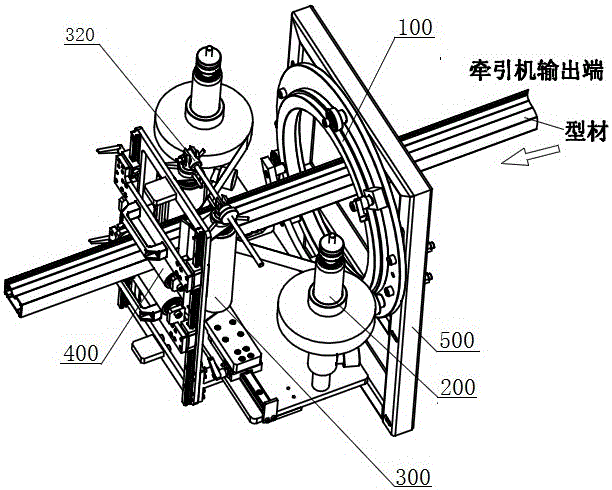

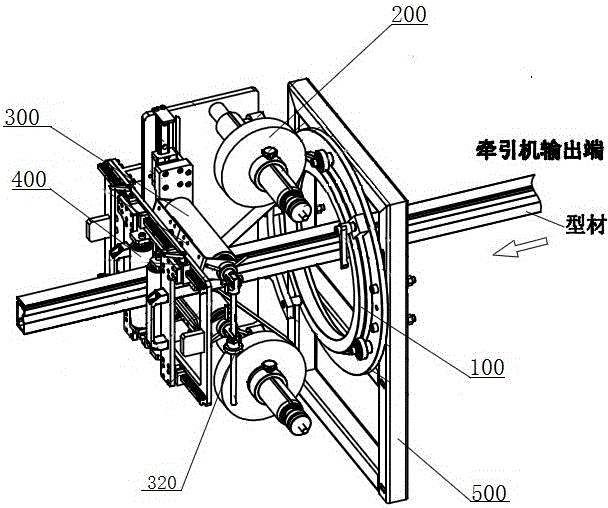

[0039] like figure 1 and 2 As shown in the figure, an online automatic film laminating machine for profiles is installed on the output end of the tractor, and includes a support frame 500 installed on the output end of the tractor that allows the profiles to pass through. The roller device 300 and the limiting roller device 400 also include a rotating device 100, the rotating device 100 is fixed on one side of the support frame 500, and the discharging device 200, the pressing roller device 300 and the limiting roller device 400 are arranged at the The profiles are arranged on the rotating device 100 in sequence in the forward direction. The rotation of the rotating device 100 drives the rotation of the discharging device 200 , the pressing roller device 300 and the limiting roller device 400 at the same time.

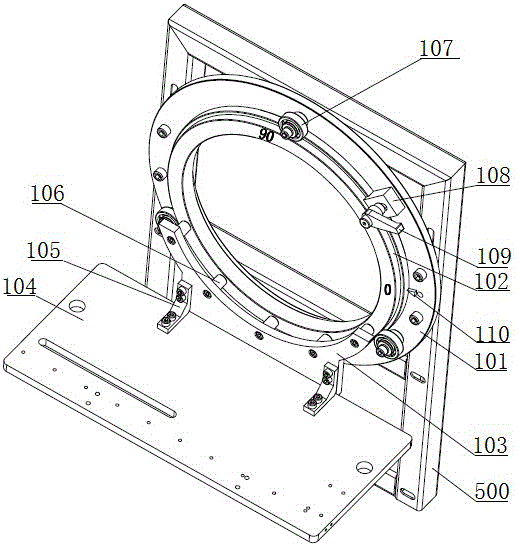

[0040] like image 3 As shown, the rotating device 100 includes an annular fixed disk 101, an annular rotating disk 102 and a mounting plate 104, the annular fixed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com