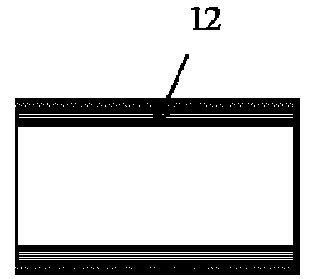

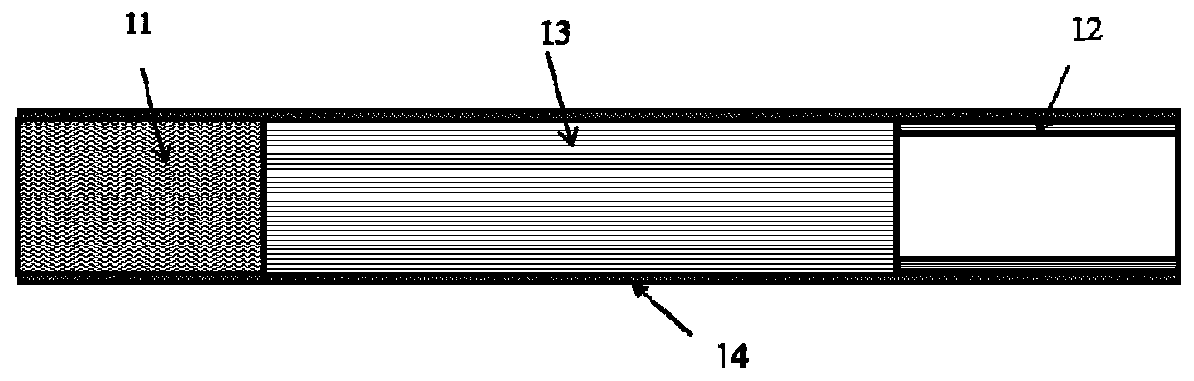

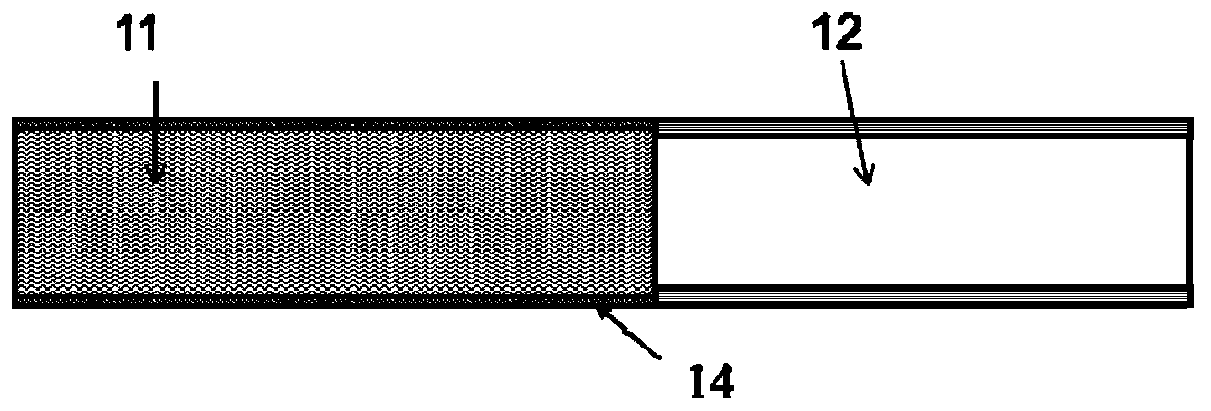

High-density hollow filter tip and composite filter tip thereof

A high-density, hollow nozzle technology, used in nozzle structure and composite nozzle field, can solve the problems of difficult to maintain the stiffness of the hollow tube, complicated process, and unfavorable heat conduction to the outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The preparation and implementation steps of the high-density cellulose acetate hollow-mouth rod are as follows:

[0067] 1) After drying 700g cellulose acetate (acetyl substitution degree 2.45, intrinsic viscosity 1.54dL / g, number average molecular weight 37000, weight average molecular weight 63000, Mw / Mn 1.7) at 120°C for 2 hours, mix with 300g triacetic acid Glycerides were fully mixed for 20 minutes in a mixer with a rotating speed of 800 rpm, and then master batches were obtained using a twin-screw extruder. The parameter temperature of the twin-screw machine is 130 / 150 / 165 / 180 / 190 / 195 / 190°C, the head pressure of the extruder is 0.2-0.4Mpa, the screw speed is 50-90 rpm, and the feeding frequency is 25- 50Hz. Use the Ceast MF20 melt index tester to test the melt index of the material to be 100 g / 10 minutes, the test condition is 210° C., and the weight is 10 kg.

[0068] 2) Use a single-screw extruder to extrude the mixed masterbatch at a temperature of 185-200°C,...

Embodiment 2

[0073] The preparation and implementation steps of polypropylene hollow mouth rod are as follows:,

[0074] 1) Use polypropylene produced by Yanshan Petrochemical as raw material to prepare PP empty pipes. The melt index of the material is 2.77 g / 10 minutes, and it is tested with a Ceast MF20 melt index tester, the test condition is 210° C., and the weight is 2.16 kg.

[0075] 2) Use a single-screw extruder to extrude the PP material at a temperature of 220-240°C, extrude and blow mold it through an empty tube die, and compress the air pressure at 0.2-0.6Mpa to obtain an outer diameter of 7mm and a wall thickness of 0.2- The 0.3mm empty tube is cooled, air-dried, and cut into 200mm long milky white empty tube.

Embodiment 3

[0077] The preparation and implementation steps of polylactic acid hollow mouth rod are as follows:

[0078] 1) Use polylactic acid produced by Zhejiang Hisun Biomaterials Co., Ltd. as a raw material to prepare PLA empty tubes. The melt index of the material is 10.5 g / 10 minutes, and it is tested with a Ceast MF20 melt index tester, the test condition is 210°C, and the mass of the weight is 2.16kg.

[0079] 2) Use a single-screw extruder to extrude the polylactic acid material at a temperature of 200-220°C, extrude and blow mold it through an empty tube die, and compress the air pressure at 0.2-0.6Mpa to obtain an outer diameter of 7mm and a wall thickness of 0.2 -0.3mm empty tube, after cooling, air drying, cut into 200mm long milky white empty tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com