Long-acting renewable antibacterial coating on surface of titanium implant

A technology of antibacterial coating and titanium implant, which is applied in the field of oral biomedical materials, can solve the problems of disappearance of antibacterial activity on the surface of the implant, rapid analysis of antibacterial components, slow release rate and reduced efficiency, and achieve the prevention of peri-implantitis , Antibacterial effect is long, and the effect of antibacterial layer is firm and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]This embodiment is a method for preparing a renewable antibacterial coating on the surface of a titanium implant provided by the present invention, comprising the following steps:

[0051] (1) Take a circular titanium sheet with a diameter of 9.5mm and a thickness of 0.3mm and polish it step by step with #400, #800, #1000SiC sandpaper, and then ultrasonically clean it with solvent acetone, absolute ethanol and double distilled water for 20min, dry;

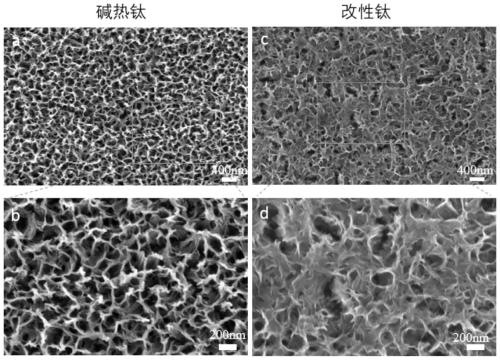

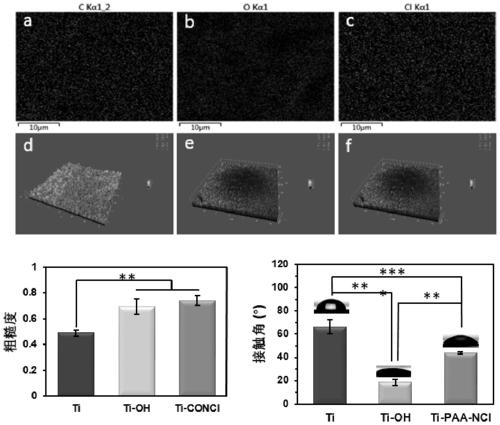

[0052] (2) React the titanium sheet treated in step (1) with 5mol / L NaOH solution at 60°C for 24 hours for alkali heat treatment to hydroxylate the surface of the titanium sheet, and then treat it with a 40% volume fraction of silane coupling agent KH570 solution , which can react with hydroxyl groups on the titanium surface, thereby introducing C=C double bonds into the surface of the titanium sheet;

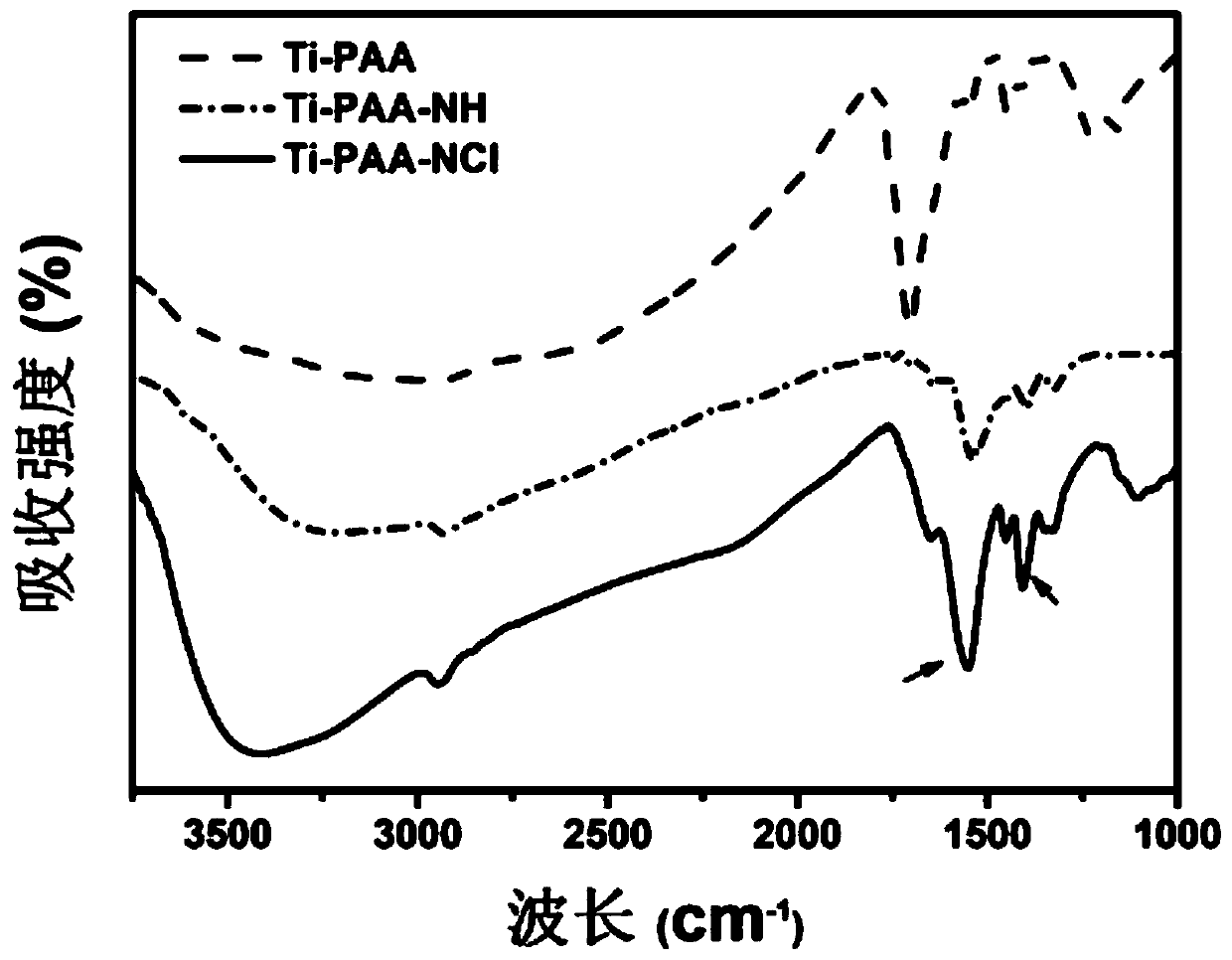

[0053] (3) Carrying out radical polymerization reaction of the titanium sheet after step (2) and acrylic acid monomer at 6...

Embodiment 2

[0057] This embodiment is a method for preparing a renewable antibacterial coating on the surface of a titanium implant provided by the present invention, comprising the following steps:

[0058] (1) Take a circular titanium sheet with a diameter of 9.5mm and a thickness of 0.3mm and polish it step by step with #400, #800, #1000SiC sandpaper, and then ultrasonically clean it with solvent acetone, absolute ethanol and double distilled water for 20min, dry;

[0059] (2) React the titanium sheet treated in step (1) with 5mol / L NaOH solution at 60°C for 24 hours for alkali heat treatment to hydroxylate the surface of the titanium sheet, and then treat it with a 40% volume fraction of silane coupling agent KH570 solution , which can react with hydroxyl groups on the titanium surface, thereby introducing C=C double bonds into the surface of the titanium sheet;

[0060] (3) Carrying out radical polymerization reaction of the titanium sheet after step (2) and acrylic acid monomer at ...

Embodiment 3

[0064] This embodiment is a method for preparing a renewable antibacterial coating on the surface of a titanium implant provided by the present invention, comprising the following steps:

[0065] (1) Take a circular titanium sheet with a diameter of 9.5mm and a thickness of 0.3mm and polish it step by step with #400, #800, #1000SiC sandpaper, and then ultrasonically clean it with solvent acetone, absolute ethanol and double distilled water for 20min, dry;

[0066] (2) React the titanium sheet treated in step (1) with 5mol / L NaOH solution at 60°C for 24 hours for alkali heat treatment to hydroxylate the surface of the titanium sheet, and then treat it with a 40% volume fraction of silane coupling agent KH570 solution , which can react with hydroxyl groups on the titanium surface, thereby introducing C=C double bonds into the surface of the titanium sheet;

[0067] (3) Carrying out the radical polymerization reaction of the titanium sheet after step (2) and the acrylic acid mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com