A segmented spiral stirring biomass pyrolysis liquefaction system

A biomass pyrolysis and spiral stirring technology, applied in mixers with rotating stirring devices, biofuels, dissolving and other directions, can solve the problems of poor heat transfer effect, weak material handling capacity, uneven temperature distribution, etc. Longer time, increased residence time, improved heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

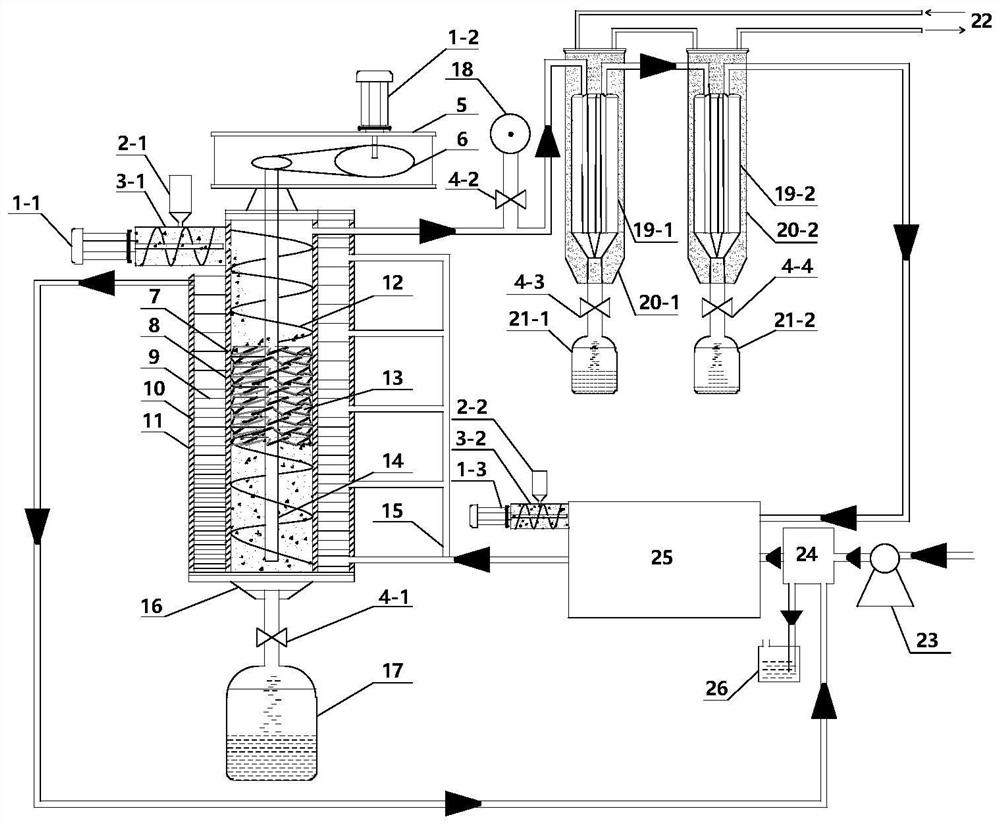

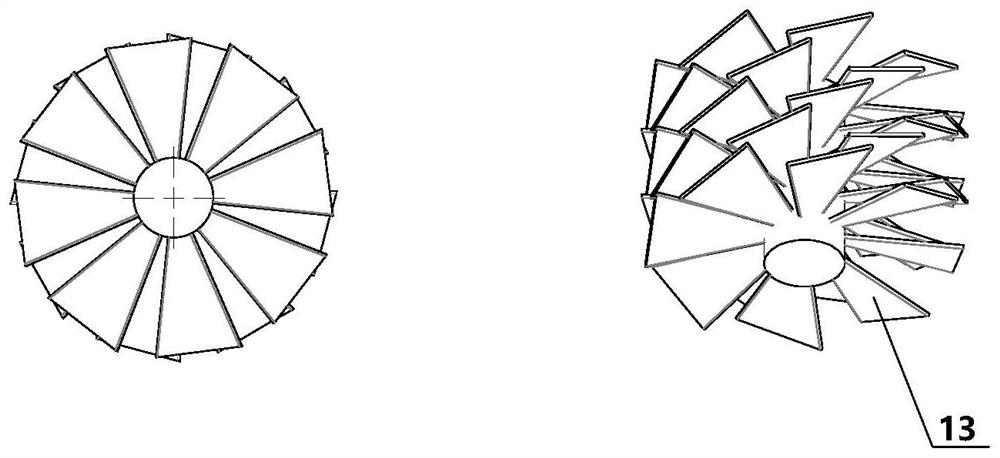

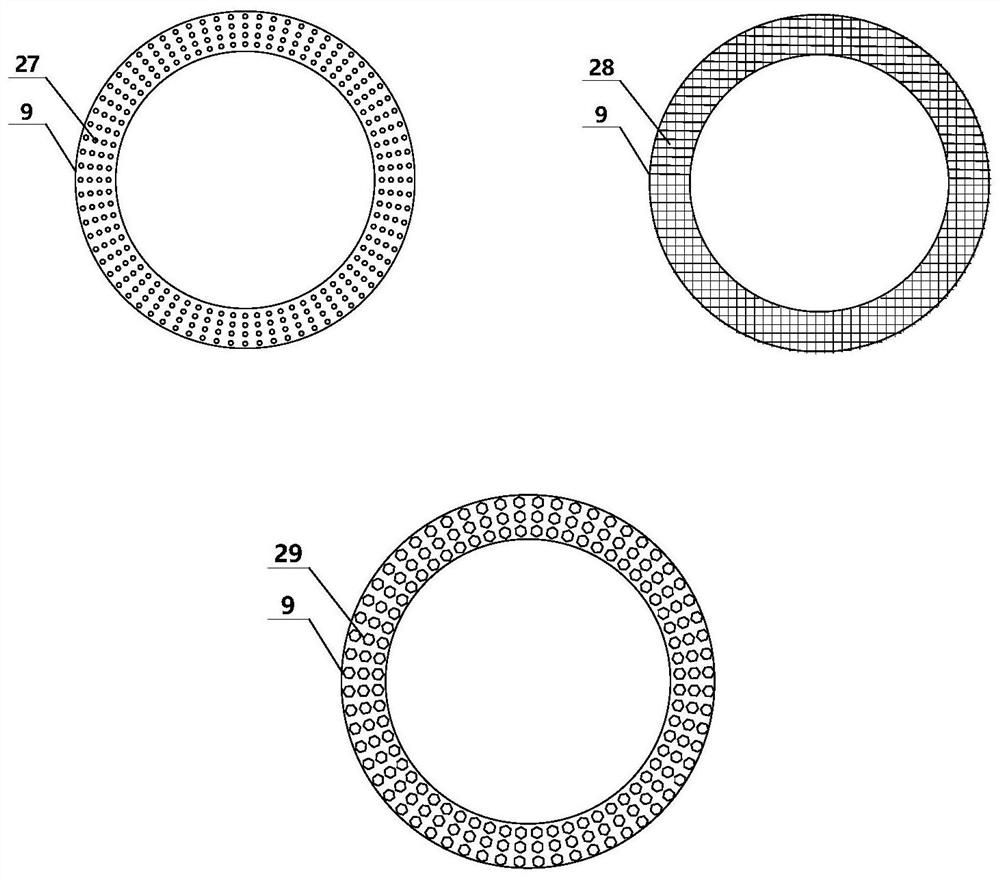

[0023] As shown in the figure, a segmented spiral stirring biomass pyrolysis liquefaction system includes a biomass powder feeding system, a segmented spiral stirring reactor, a gear system, a carbon collector, a heating system, a condensation system, and a flue gas Processing device. The feed port of the reactor body 7 is connected to the discharge port of the first biomass powder feeder 3-1, and the inside of the reactor body 7 has a stirring shaft 14, a spiral blade 12 and a retaining blade 13, and the upper part of the stirring shaft 14 is connected with the gear The system 6 is connected, the gear system 6 is fixed by the gear frame 5 arranged on the top of the reactor body 7, and is powered by the second AC motor 1-2, the outlet of the reactor body 7 bottom is connected with the carbon collector 17 through the perforated screen 16, The reactor body 7 is surrounded by a sleeve body heat transfer device 11, and the right part is connected with the first condensation pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com