Hot-rolled high-carbon steel production method

A production method and technology for high carbon steel, applied in the direction of metal rolling, metal rolling, heat treatment furnace, etc., can solve the problems of difficult to achieve cold-rolled thin-sized products, large cold-rolling rolling force, etc., and achieve good cold-working performance. , the effect of hardness reduction, toughness and ductility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

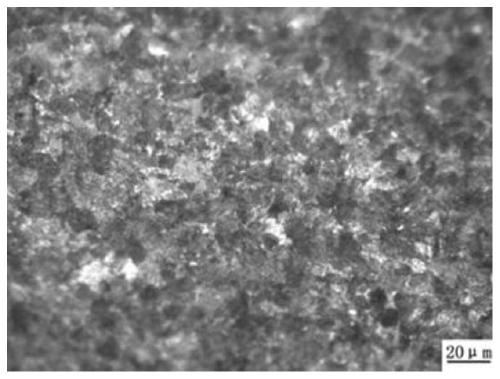

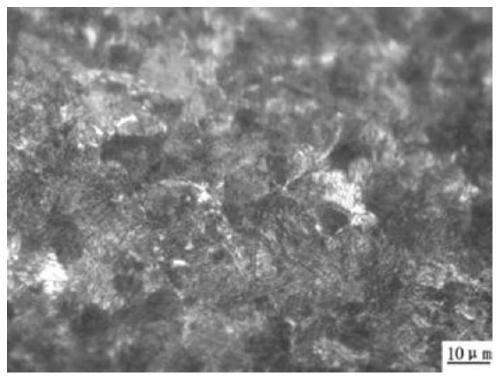

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments.

[0026] (1) The chemical composition and weight percentage of the high-carbon steel described in the present invention are: C: 0.47-0.55%, Si≤0.40%, Mn: 0.80-1.0%, P≤0.025%, S≤0.015%, Cr ≤0.20%, Ni≤0.30%, Cu≤0.30%, N≤0.006%, the balance is Fe and unavoidable impurity elements.

[0027] Examples 1-10 The chemical composition and weight percentage of the hot-rolled high-carbon steel are shown in Table 1.

[0028] (2) The production method of hot-rolled high-carbon steel described in the present invention includes converter vanadium extraction, converter smelting, LF refining, slab continuous casting, slab heating, high-pressure water descaling, controlled rolling, laminar cooling, coiling process;

[0029] The slab heating process heats the slab to 1180-1210°C, and the heating time is ≤140min;

[0030] The controlled rolling process includes rough rolling and fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com