A thermal insulation block prepared by using plant fiber modified spoil and its preparation method

A plant fiber, thermal insulation block technology, applied in applications, ceramic products, manufacturing tools, etc., can solve the problems of large skeleton frame, low thermal insulation performance, etc., and achieve reduced collapse, good thermal stability, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

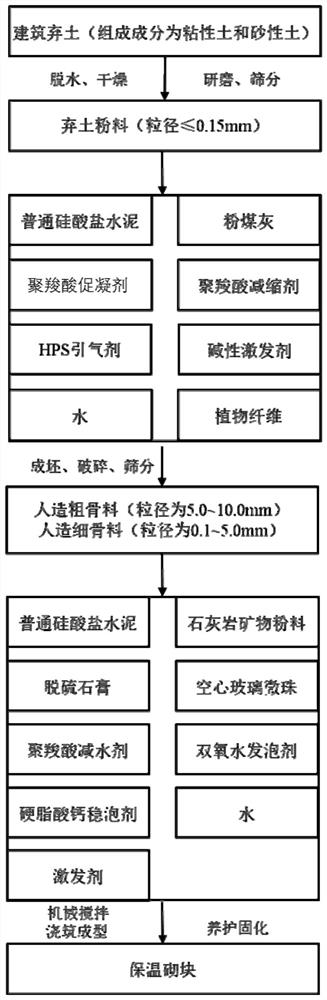

Method used

Image

Examples

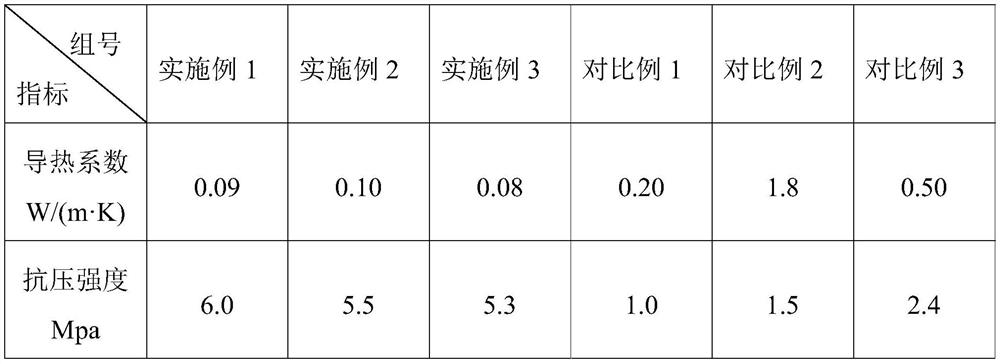

Embodiment 1

[0036] Collect composite construction spoil with a ratio of sandy soil and clayey soil of 3:1, and the content of impurities in the spoil is <0.1%. The spoil is dehydrated, dried, ground, and sieved to obtain spoil powder 1# with a particle size of 0.045-0.105 mm.

[0037]Select crop stalks and rice straw as plant fiber raw materials. After removing the leaves, nodes, ears and other parts of the crop straw, it is mixed with rice straw, and after dust removal, shearing and crushing, the length of the obtained fiber is controlled at 0.1-5.0mm. Then soak the above-mentioned plant fibers in a polylactic acid resin solution with a concentration of 3% and a particle size of polylactic acid resin of 1.0-2.0 μm for 40 minutes, and then vacuum-dry them at 50°C, and the polylactic acid resin forms a film on the surface of the plant fibers to form a plant. Fiber 1#, collected for later use.

[0038] In parts by weight, take 280 parts of spoil powder 1#, 90 parts of ordinary Portland ce...

Embodiment 2

[0042] Collect composite construction spoil with a ratio of sandy soil and clayey soil of 4:1, and the content of impurities in the spoil is <0.1%. The spoil is dehydrated, dried, ground, and sieved to obtain spoil powder 2# with a particle size of 0.045-0.105 mm.

[0043] Sawdust and straw are selected as plant fiber raw materials. After the two kinds of fibers are mixed, the length of the obtained fibers is controlled within 0.1-5.0 mm after dust removal, shearing and crushing. Then soak the above-mentioned plant fibers in a polylactic acid resin solution with a concentration of 3% and a particle size of polylactic acid resin of 1.0-2.0 μm for 40 minutes, and then vacuum-dry them at 50°C, and the polylactic acid resin forms a film on the surface of the plant fibers to form a plant. Fiber 2#, collected for later use.

[0044] According to parts by weight, take 300 parts of spoil powder 2#, 100 parts of ordinary Portland cement, 25 parts of fly ash, 3 parts of alkaline activ...

Embodiment 3

[0048] Collect composite construction spoil with a ratio of sandy soil and clayey soil of 3:1, and the content of impurities in the spoil is <0.1%. The spoil is dehydrated, dried, ground, and sieved to obtain spoil powder 3# with a particle size of 0.045-0.105 mm.

[0049] Sawdust and straw are selected as plant fiber raw materials. After the two kinds of fibers are mixed, the length of the obtained fibers is controlled within 0.1-5.0 mm after dust removal, shearing and crushing. Then soak the above-mentioned plant fibers in a polylactic acid resin solution with a concentration of 3% and a particle size of polylactic acid resin of 1.0-2.0 μm for 40 minutes, and then vacuum-dry them at 50°C, and the polylactic acid resin forms a film on the surface of the plant fibers to form a plant. Fiber 3#, collected for later use.

[0050] In parts by weight, take 250 parts of spoil powder 3#, 85 parts of ordinary Portland cement, 30 parts of fly ash, 4 parts of alkaline activator, 12 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com