Tow prepreg, composite material high-pressure hydrogen storage tank and preparation process of composite material high-pressure hydrogen storage tank

A technology of composite materials and prepregs, applied in the direction of fixed-capacity gas storage tanks, mechanical equipment, pressure vessels, etc., can solve problems such as weak shear strength, fatigue damage of the matrix, hydrogen storage density limited by the size of the pressure, etc. , achieve excellent weather resistance and fatigue resistance, solve the effect of poor dispersion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

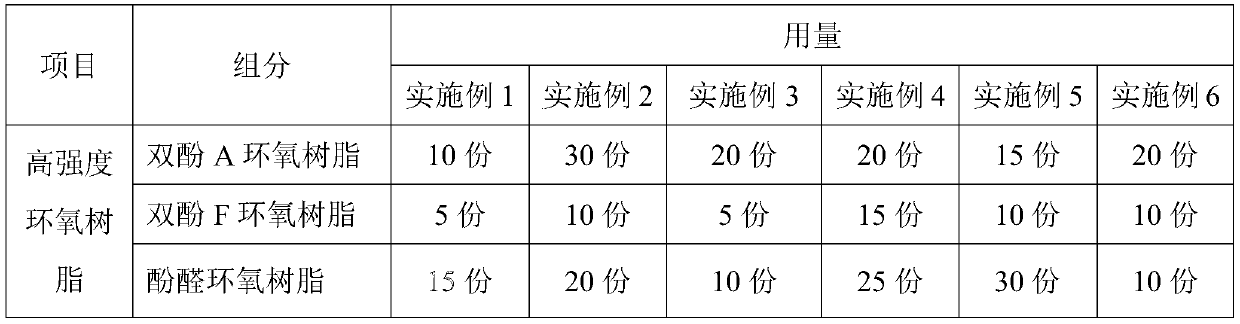

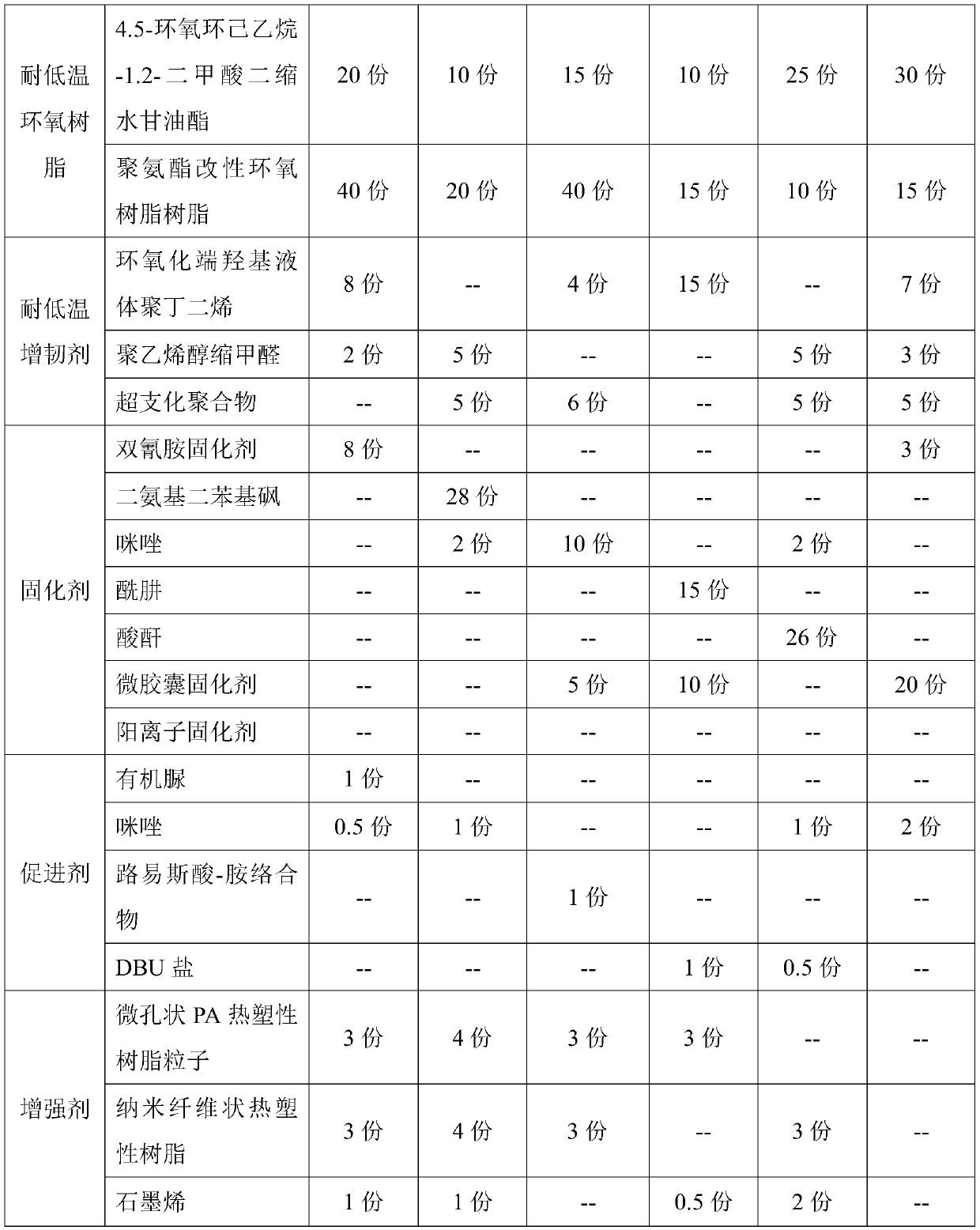

Embodiment 1-6

[0075] An epoxy resin tow prepreg comprises carbon fiber, a special fiber sizing agent for epoxy resin and an epoxy resin composition that are sequentially dip-coated on the surface of the fiber.

[0076] Above-mentioned special fiber sizing agent for epoxy resin comprises the following components by weight:

[0077] 60 parts of solid epoxy resin, 25 parts of liquid epoxy resin, 30 parts of deionized water, 6 parts of epoxy resin emulsifier, 3 parts of epoxy resin coupling agent, and 3 parts of epoxy resin surfactant.

[0078] Wherein, the solid epoxy resin comprises 4 parts by weight of high molecular weight bisphenol A epoxy resin, 3 parts by weight of novolak epoxy resin, and 2 parts by weight of high molecular weight hydantoin epoxy resin;

[0079] The liquid epoxy resin comprises 4 parts by weight of low molecular weight bisphenol A epoxy resin, 3 parts by weight of bisphenol F epoxy resin, 1 part by weight of low molecular weight novolak epoxy resin, 1 part by weight of ...

Embodiment 1

[0086] The epoxy resin tow prepreg of embodiment 1 is prepared by the following process:

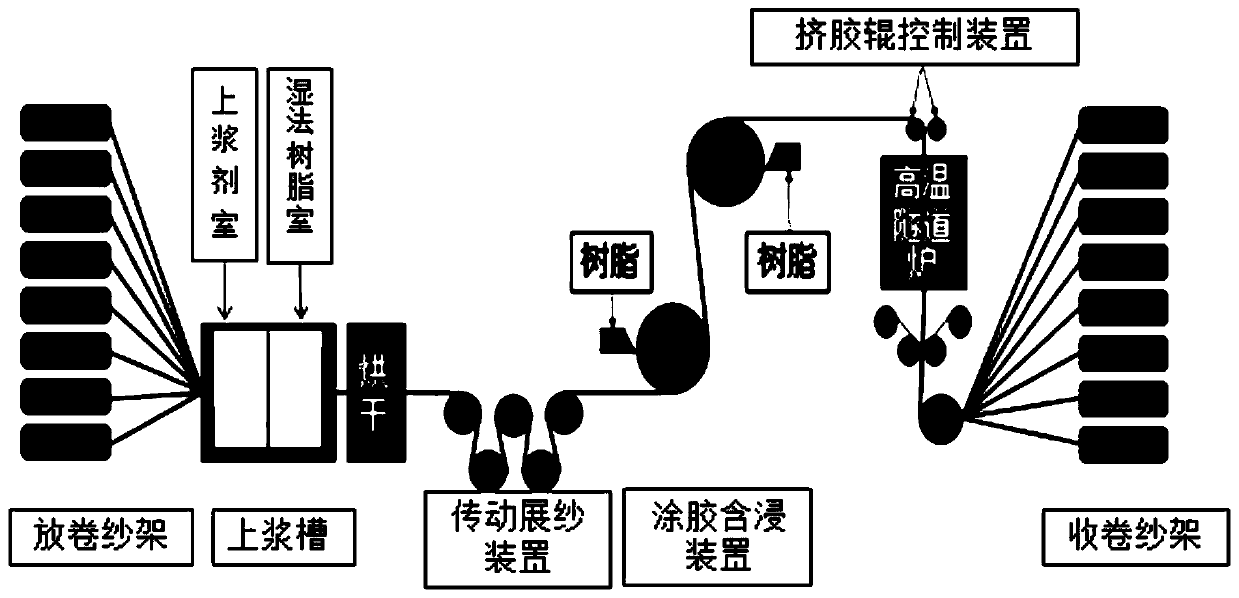

[0087] use figure 1 In the preparation system shown, the carbon fiber is unrolled on the unwinding creel, the wet resin chamber in the sizing tank is closed, and the fiber is sizing with the special fiber sizing agent for epoxy resin in Example 1 in the sizing chamber, and the fiber is sizing through transmission and After spreading, the epoxy resin composition of embodiment 1 is coated on the two rollers of the gluing and impregnating device, rolled onto the fiber by the rollers, and then the resin content is controlled to be 35% by the squeeze roller control device, and finally Carry out winding on the creel, and protect the tow prepreg with a film during winding;

[0088] The preparation process of the epoxy resin tow prepreg in Examples 2-6 is the same as in Example 1, and will not be repeated here.

Embodiment 7

[0090] A PA thermoplastic resin tow prepreg comprises PA tow, a PA special fiber sizing agent and a PA thermoplastic resin composition that are sequentially dip-coated on the surface of the PA tow.

[0091] The above-mentioned special fiber sizing agent for PA comprises the following components in parts by weight: 50 parts of polyurethane resin, 60 parts of alcohol-soluble polyamide resin, 6 parts of bisphenol A epoxy resin, 2 parts of bisphenol F epoxy resin, phenolic ring 2 parts of oxygen resin, 50 parts of alcohol, 60 parts of deionized water, 6 parts of PA sizing agent emulsifier, 5 parts of PA sizing agent coupling agent, and 6 parts of PA sizing agent surfactant.

[0092] Among them, the PA sizing agent emulsifier is polyether dialkyl ester and carboxymethyl cellulose; the PA sizing agent coupling agent is epoxy silane coupling agent, amino silane coupling agent, epoxy silane coupling agent, The weight ratio of aminosilane coupling agent is 1:5; PA sizing agent surfacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com