ZrCO-based high-entropy intermetallic compounds with stable isomorphic hydrogen absorption/desorption reactions and their preparation and application

A technology of intermetallic compounds and isomorphs, applied in the direction of non-metallic elements, chemical instruments and methods, hydrogen, etc., can solve the problems of low crystal structure stability, cycle capacity decay, etc., and achieve good crystal structure stability and safety High, the effect of avoiding disproportionation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The chemical composition of ZrCo-based high-entropy intermetallic compounds is Zr 0.8 Nb 0.2 Co 0.6 Cu 0.2 Ni 0.2 , and calculate the addition amount of Zr, Nb, Co, Cu, and Ni elemental raw materials according to the above chemical formula. Among them, the purity of the elemental raw materials of Zr, Nb, Co, Cu, and Ni all used reached more than 99%. The above-mentioned raw materials are weighed according to the calculated addition amount after cleaning and drying. The weighed raw materials are placed in the water-cooled copper crucible of the magnetic levitation induction melting furnace. After being evacuated and exhausted to a vacuum degree of 0.8 Nb 0.2 Co 0.6 Cu 0.2 Ni 0.2 High-entropy intermetallic compound ingots.

Embodiment 2

[0046] The chemical composition of ZrCo-based high-entropy intermetallic compounds is Zr 0.75 Nb 0.25 Co 0.5 Cu 0.25 Ni 0.25 , and calculate the addition amount of Zr, Nb, Co, Cu, and Ni elemental raw materials according to the above chemical formula. Among them, the purity of the elemental raw materials of Zr, Nb, Co, Cu, and Ni all used reached more than 99%. The above-mentioned raw materials are weighed according to the calculated addition amount after cleaning and drying. The weighed raw materials are placed in the water-cooled copper crucible of the magnetic levitation induction melting furnace. After being evacuated and exhausted to a vacuum degree of 0.75 Nb 0.25 Co 0.5 Cu 0.25 Ni 0.25 High-entropy intermetallic compound ingots.

Embodiment 3

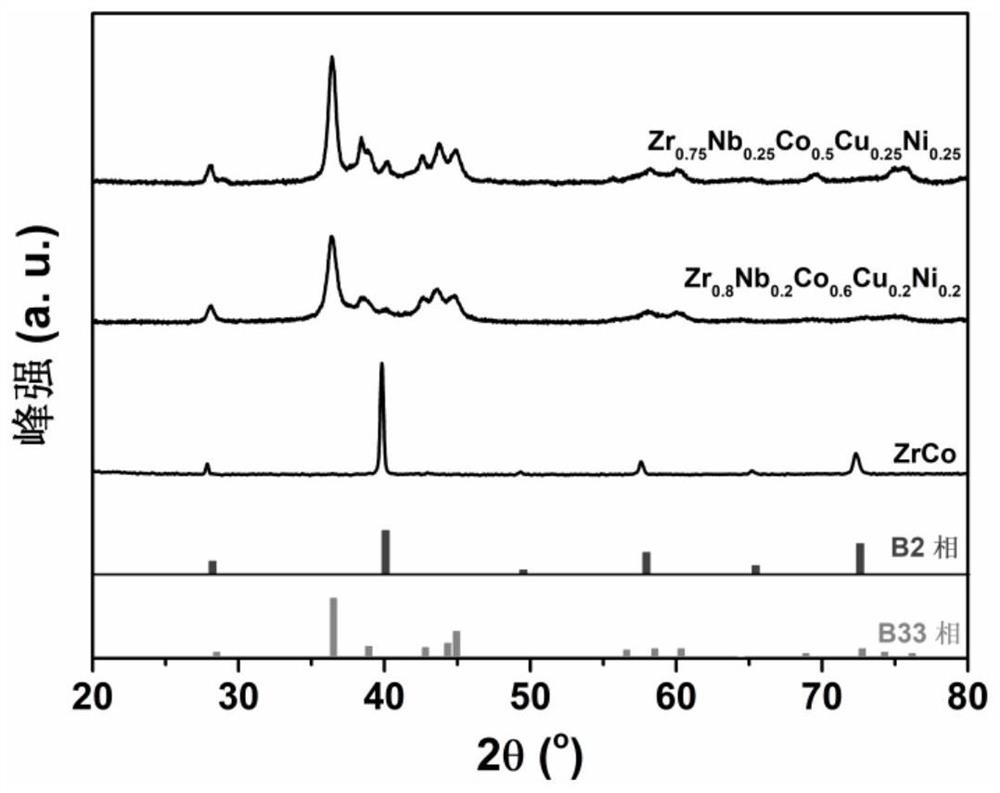

[0048] The XRD patterns of the ingots of Comparative Example 1 and Examples 1-2 are as follows figure 1 It can be found that with the increase of the substitution amount of Nb, Cu and Ni, the main phase changes to the orthorhombic B33 phase, which indicates that the increase of the multi-component substitution is beneficial to change its crystal structure and enhance the orthorhombic B33 phase stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com