Dispersedly distributed metal silicide/nano-silicon composite material and preparation method thereof

A metal silicide and composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of coarse particle size of metal phase, limited enhancement effect, and difficulty in uniform distribution, etc. The preparation process is simple, the cost is low, and the performance is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

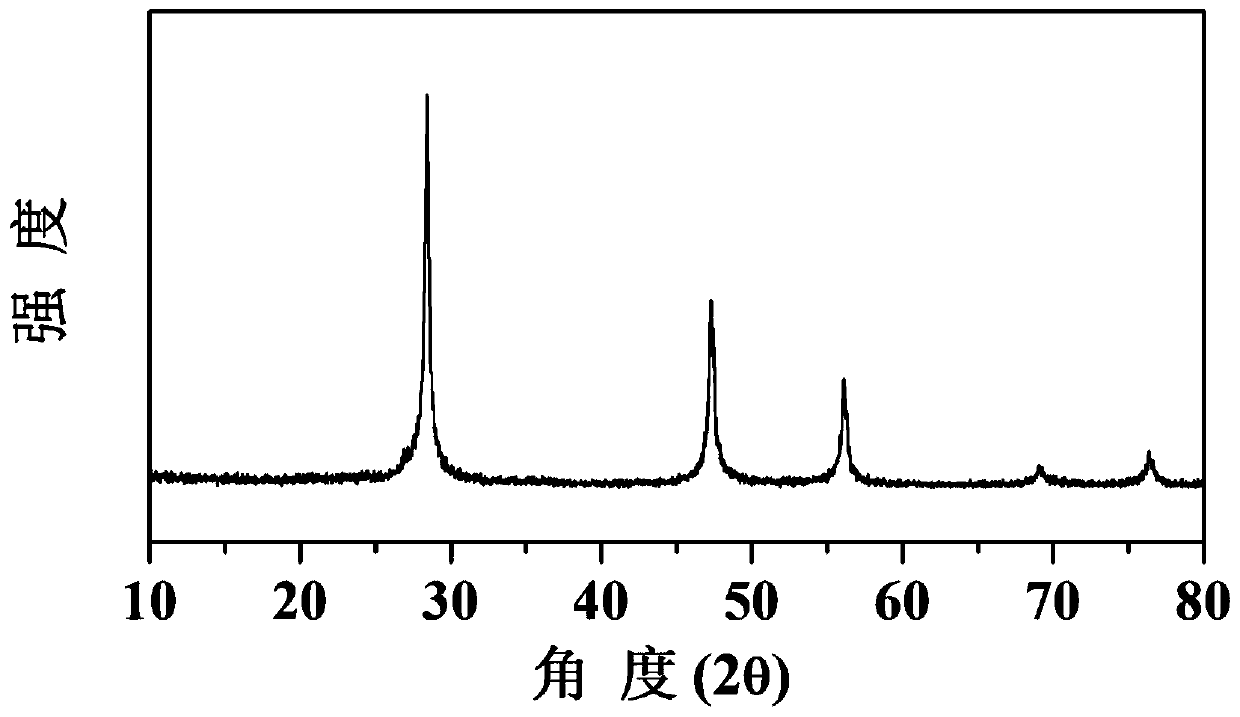

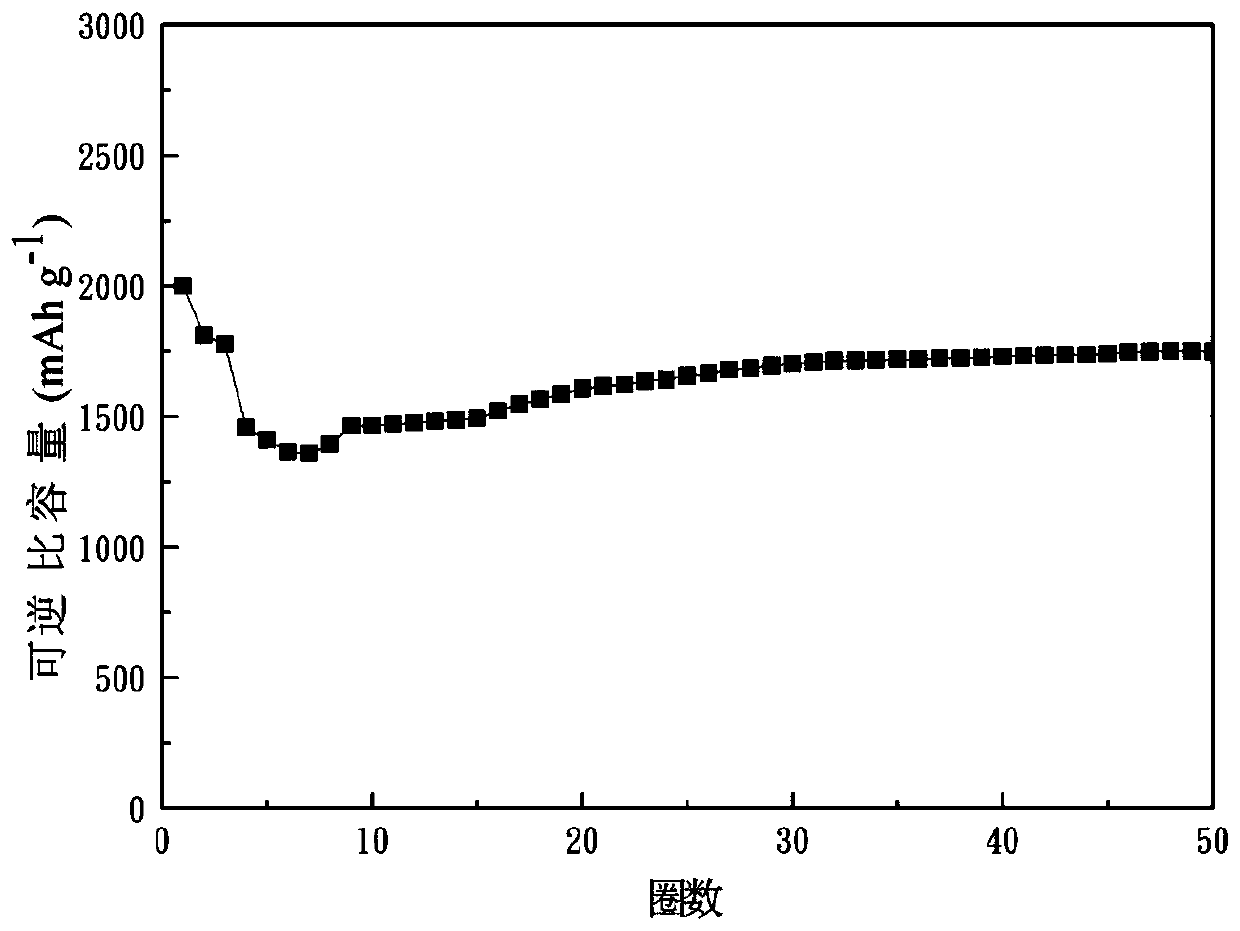

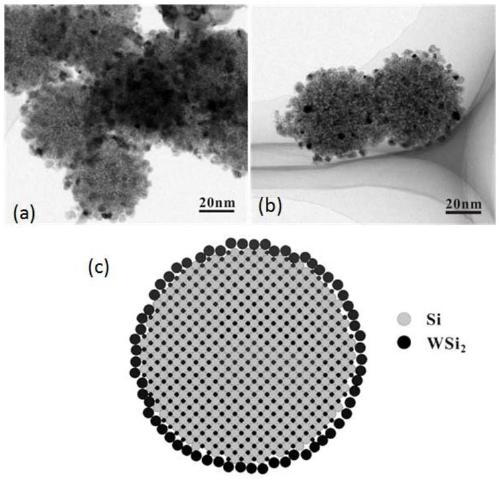

Embodiment 1

[0028] 1. Disperse 4.5ml of tetraethyl orthosilicate in 45mL of ethanol to obtain mixed solution 1; disperse 1.38g of ammonium metatungstate and 3.83g of urea in a solvent composed of 41mL of ethanol and water (volume ratio of ethanol and water is 16: 25), the mixed solution 2 is obtained, wherein the molar ratio of tungsten and silicon added is 1:3 (calculation of this molar ratio: it is the molar ratio of silicon and metal elements in silicon dioxide produced by the theoretical hydrolysis of liquid silicon source ratio, the same as in subsequent examples); Pour the mixed solution 2 into the mixed solution 1 quickly, and stir at 650r / min at room temperature for 30min, and then carry out a hydrothermal reaction at 200°C for 12h to obtain a colloidal Precipitate, filter, and wash the precipitate with water to be neutral, and dry at 60°C to obtain a tungsten silicide / silicon dioxide composite precursor.

[0029] 2. Take 1g of tungsten silicide / silicon dioxide composite precursor...

Embodiment 2

[0050] 1. Disperse 4.5ml tetraethyl orthosilicate in 45mL ethanol to obtain mixed solution 1; disperse 1.03g ammonium metatungstate and 3.834g urea in a solvent composed of 41mL ethanol and water (volume ratio of ethanol and water is 16: 25), the mixed solution 2 was obtained, wherein the molar ratio of tungsten and silicon added was 1:4; the mixed solution 2 was quickly poured into the mixed solution 1, and stirred at 650r / min at room temperature for 30min, and then it was The hydrothermal reaction was carried out at 200°C for 12 hours to obtain a colloidal precipitate, which was filtered, washed with water and turned neutral, and dried at 60°C to obtain a tungsten silicide / silicon dioxide composite precursor.

[0051] 2. Take 1g of tungsten silicide / silicon dioxide composite precursor powder, mix it with 10g of sodium chloride, add 0.9g of metal magnesium powder, put it in a sealed tube furnace, and raise the temperature at 5°C / min to Keep warm at 400°C for 0.5h, then raise ...

Embodiment 3

[0058] 1. Disperse 4.5ml tetraethyl orthosilicate in 45mL ethanol to obtain mixed solution 1; disperse 0.69g ammonium metatungstate and 3.834g urea in a solvent composed of 41mL ethanol and water (volume ratio of ethanol and water is 16: 25), the mixed solution 2 was obtained, wherein the molar ratio of tungsten and silicon added was 1:6; the mixed solution 2 was quickly poured into the mixed solution 1, and stirred at room temperature for 30 min at 650 r / min, and then it was The hydrothermal reaction was carried out at 190°C for 24 hours to obtain a colloidal precipitate, which was filtered and washed with water to be neutral, and dried at 60°C to obtain a tungsten silicide / silicon dioxide composite precursor.

[0059]2. Take 1g of metal silicide / silicon dioxide composite precursor powder, mix it with 10g of sodium chloride, add 0.9g of metal magnesium powder, put it in a sealed tube furnace, and raise the temperature at 5°C / min under an argon atmosphere Heat at 400°C for 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com