Acid-rain-resistant elastic texture paint and preparation method thereof

A technology for brushing paint and acid rain resistance, applied in anti-corrosion coatings, coatings, etc., can solve the problem of lack of acid rain resistance, achieve good extensibility, and make up for cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

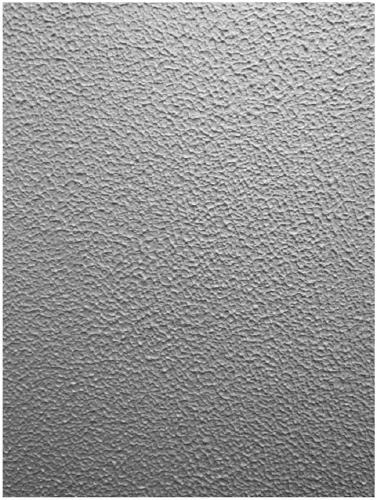

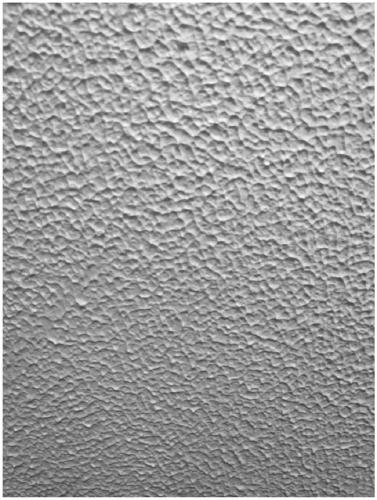

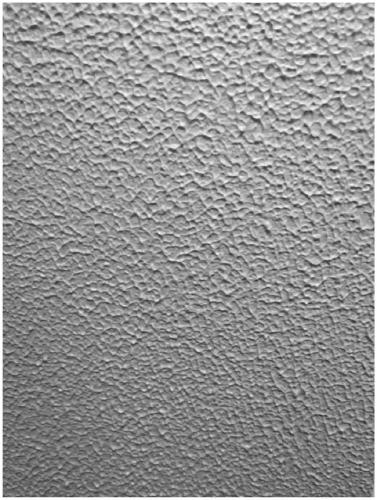

Image

Examples

Embodiment 1

[0047] A preparation method of an acid rain-resistant elastic brushed paint, specifically as follows:

[0048] (1) Weigh 11 parts of water based on 100 parts by weight, and add ammonium salt dispersant DRAFT OROTAN1618: 0.6 parts, wetting agent TRITON EF-106: 0.1 parts, defoamer Efka 2580: 0.3 parts, bentonite BENAQUA 4000: 0.35 parts, propylene glycol 1.0 parts, pH regulator AMP-95: 0.25 parts; disperse for 5 minutes;

[0049] (2) At 800-1000 rpm, add rutile titanium dioxide 668: 10.0 parts, barium sulfate 5AA; 37.5 parts, and disperse for 20-30 minutes at 1000-1300 rpm; Degree ≤ 50 microns;

[0050] (3) At a speed of 500-800 rpm, add in sequence Archsol 8015A: 37 parts of elastic emulsion, TEXANOL: 0.5 parts of film-forming aid, 0.3 parts of fungicide ROCIMA631, and 0.3 parts of defoamer BYK-019, After dispersing for 10 minutes;

[0051] (4) Add thickeners ACRYSOL DR-72: 0.6 parts and ACRYSOLDR-50: 0.2 parts at a speed of 800 to 1000 rpm, increase the speed as the viscosi...

Embodiment 2

[0053] A preparation method of an acid rain-resistant elastic brushed paint, specifically as follows:

[0054] (1) Weigh 11 parts of water based on 100 parts by weight, and add ammonium salt dispersant DISPEX CX4240: 0.6 parts, wetting agent ECOSURF BD-109: 0.1 parts, defoamer at a speed of 300 to 500 rpm Efka 2580: 0.3 parts, bentonite BENAQUA 4000: 0.25 parts, propylene glycol 1.0 parts, pH regulator AMP-95: 0.25 parts; disperse for 5 minutes;

[0055] (2) Add rutile titanium dioxide 668: 10.0 parts, barium sulfate 5AA: 37.5 parts at 800-1000 rpm, and disperse for 20-30 minutes at 1000-1300 rpm; quality inspection sampling inspection Fineness≤50 microns;

[0056] (3) At the speed of 500-800 rpm, add elastic emulsion ELASTENE 2471: 37 parts, film-forming aid TEXANOL: 0.5 parts, fungicide ROCIMA631: 0.3 parts, defoamer BYK-019: 0.3 parts, Disperse for 10 minutes;

[0057](4) Add ACRYSOL DR-72: 0.6 parts and ACRYSOLDR-50: 0.3 parts to the thickener at a speed of 800-1000 rpm...

Embodiment 3

[0059] A preparation method of an acid rain-resistant elastic brushed paint, specifically as follows:

[0060] (1) Weigh 11 parts of water based on 100 parts by weight, and add ammonium salt dispersant DISPEX CX4240: 0.6 parts, wetting agent TRITON EF-106: 0.1 parts, defoamer at a speed of 300 to 500 rpm Efka 2580: 0.3 parts, propylene glycol 1.0 parts, bentonite BENAQUA 4000: 0.3 parts, pH regulator AMP-95: 0.25 parts; disperse for 5 minutes;

[0061] (2) At 800-1000 rpm, add rutile titanium dioxide 668: 10.0 parts, barium sulfate 5AA; 37.5 parts, at 1000-1300 rpm, disperse for 20-30 minutes; quality inspection sampling inspection Fineness≤50 microns;

[0062] (3) At a speed of 500-800 rpm, add in sequence Archsol 8015A: 37 parts of elastic emulsion, TEXANOL: 0.5 parts of film-forming aid, 0.3 parts of fungicide ROCIMA631, and 0.3 parts of defoamer BYK-019, Disperse for 10 minutes;

[0063] (4) Add thickener ACRYSOL DR-72: 0.8 parts at a speed of 800 to 1000 rpm, increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com