Preparation method of wood-based bionic bone scaffold material

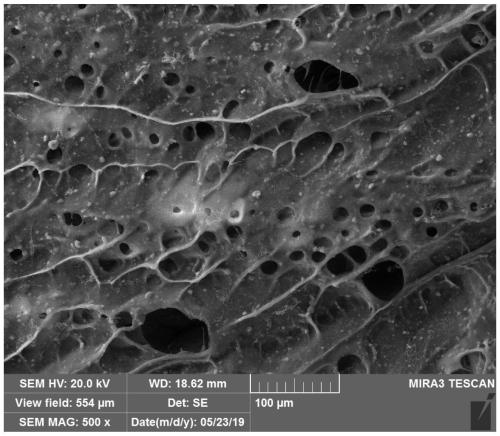

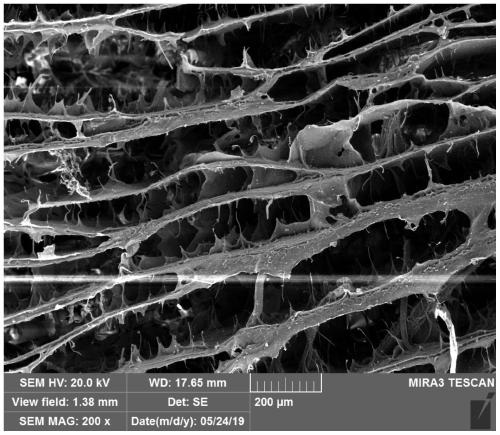

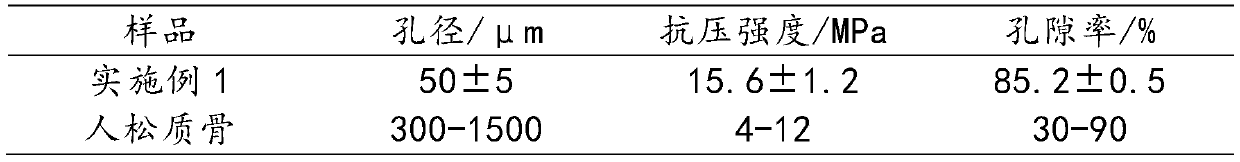

A scaffold material and bionic bone-based technology, applied in the field of bionic bone scaffolds, to achieve the effect of high three-dimensional porous structure, no cytotoxicity, and good bone cell compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Soak the wood fiber in the alkali solution prepared with 0.01mol / L sodium hydroxide solution and 0.01mol / L sodium sulfite solution according to the mass ratio of 1:1, and then perform mechanical grinding at a speed of 2800r / min Treat for 2 hours to prepare fiber pulp with a mass fraction of 10%;

[0050](2) In a water bath at 40°C, chitosan is dissolved in pure water to prepare a chitosan polymer solution with a mass fraction of 10%, and the fiber pulp with a mass fraction of 10% obtained in step 1 and 10% mass fraction The chitosan polymer solution was mixed at a mass ratio of 1:1, stirred evenly, and kept magnetically stirred in a water bath at 40°C for 0.5h to obtain a mixed solution;

[0051] (3) Add hydroxyapatite to the mixed solution obtained in step 2, and carry out magnetic stirring at 40°C in a water bath for 0.5h to obtain a scaffold material precursor mixed solution, wherein the amount of hydroxyapatite added is the same as that of chitosan and wood The...

Embodiment 2

[0056] (1) Soak the wood fiber in the alkali solution prepared with 0.01mol / L sodium hydroxide solution and 0.01mol / L sodium sulfite solution according to the mass ratio of 1:2, and then perform mechanical grinding at a speed of 2800r / min Treat for 2 hours to prepare fiber pulp with a mass fraction of 10%;

[0057] (2) In a water bath at 50°C, chitosan is dissolved in pure water to prepare a mass fraction of 10% chitosan macromolecule solution, and the fiber pulp with a mass fraction of 10% obtained in step 1 and 10% of the mass fraction The chitosan polymer solution was mixed and stirred evenly at a mass ratio of 1:2, and kept magnetically stirred in a water bath at 50°C for 0.5h to obtain a mixed solution;

[0058] (3) Add hydroxyapatite to the mixed solution obtained in step 2, and carry out magnetic stirring at 40°C in a water bath for 0.5h to obtain a scaffold material precursor mixed solution, wherein the amount of hydroxyapatite added is the same as that of chitosan and...

Embodiment 3

[0063] (1) Soak the wood fiber in the alkali solution prepared according to the mass ratio of 2:1 0.01mol / L sodium hydroxide solution and 0.01mol / L sodium sulfite solution, and then perform mechanical grinding at a speed of 2800r / min Treat for 2 hours to prepare fiber pulp with a mass fraction of 20%;

[0064] (2) In a water bath at 60°C, chitosan is dissolved in pure water to prepare a chitosan polymer solution with a mass fraction of 20%, and the fiber pulp with a mass fraction of 20% obtained in step 1 and 20% of the mass fraction The chitosan polymer solution was mixed and stirred evenly at a mass ratio of 1:1, and kept magnetically stirred in a water bath at 60°C for 0.5h to obtain a mixed solution;

[0065] (3) Add hydroxyapatite to the mixed solution obtained in step 2, and stir magnetically at 60° C. in a water bath for 0.5 h to obtain a scaffold material precursor mixed solution, wherein the amount of hydroxyapatite added is the same as that of chitosan and wood fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com