Method for constructing type III collagen photoelectrochemical sensor based on rhenium disulfide nanosheet and application

A technology of rhenium disulfide and collagen, applied in the direction of electrochemical variables of materials, nanotechnology for sensing, nanotechnology for materials and surface science, etc., can solve the problem of time-consuming, non-concentrated ultrasonic energy, and peeling effect It has the advantages of simple preparation method, concentrated ultrasonic energy, and shortened peeling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

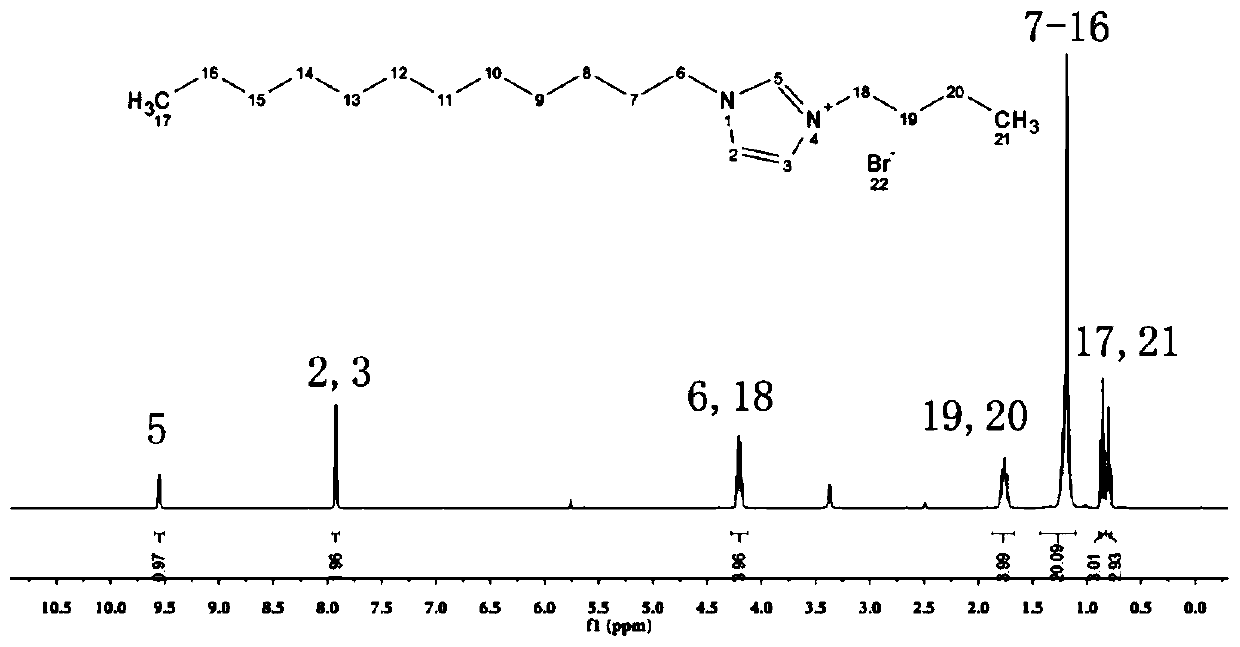

[0059] A kind of 1-butyl-3-dodecyl imidazolium bromide ionic liquid, its preparation method is as follows:

[0060] (1) Take by weighing sodium hydride (0.04mol, 0.96g) and add in the 120mL acetonitrile solution containing imidazole (0.02mol, 1.36g) several times in small amounts, form the acetonitrile suspension of white imidazole sodium after 3h of ice-bath reaction, cool to Standby at room temperature;

[0061] (2) Add bromododecane (0.01mol, 2.42g) to the acetonitrile suspension of imidazole sodium obtained in step (1), raise the temperature to 65° C., stir overnight, point the plate to monitor the reaction process, and pump out after the reaction is completed. Filter, remove insoluble impurities, and remove acetonitrile by rotary evaporation to obtain the crude product, then gradient elution through a silica gel column, the eluent is (CH 2 Cl 2 : MeOH=10:1), obtain light yellow oily liquid dodecyl imidazole;

[0062] (3) Dissolve dodecyl imidazole (0.01mol, 2.36g) and ...

Embodiment 2

[0065] A method for preparing rhenium disulfide nanosheets based on ionic liquid-assisted exfoliation, the steps are as follows:

[0066] (1) Take 0.1g of 1-butyl-3-dodecyl imidazolium bromide in a centrifuge tube, add 15mL of N-methylpyrrolidone to dissolve it completely, and then add 20mg of ReS 2 The powder is ultrasonicated with a probe ultrasonic machine, the probe ultrasonic treatment time is 3h, the power is 300W, the ultrasonic machine is set to work for 5s and pause for 2s, and the dispersed ReS 2 A solution of nanosheets;

[0067] (2) The ReS obtained in step (1) 2 The nanosheets were divided into centrifuge tubes, and centrifuged at 500rpm for 5min to remove blocky ReS 2 , the collection contains ReS 2 The supernatant of the nanosheets was centrifuged at 12,000rpm for 15min to remove the solvent, washed three times with deionized water and absolute ethanol alternately, and dried in vacuum to obtain ReS 2 Nanosheets.

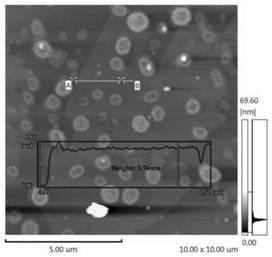

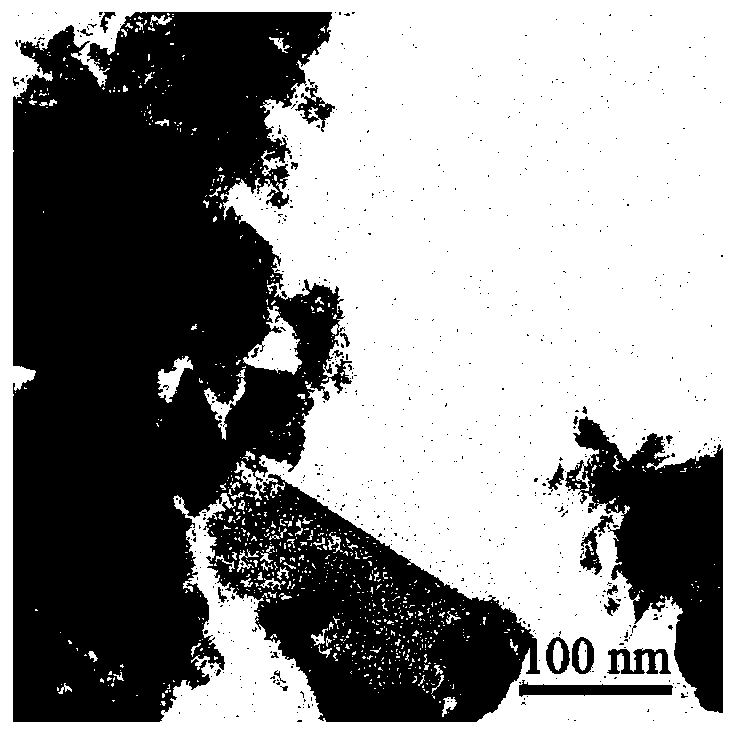

[0068] figure 2 ReS prepared for this exa...

Embodiment 3

[0074] like Figure 7 As shown, a method for constructing type III collagen photoelectrochemical sensors based on rhenium disulfide nanosheets comprises the following steps:

[0075] S1. Glassy carbon electrode pretreatment: straight bare glassy carbon electrode (diameter 3mm), with 0.3μm Al 2 o 3 The suspension was polished, rinsed with distilled water, and then successively in HNO 3 , ethanol, double distilled water ultrasonic cleaning, dry for later use;

[0076] S2, with the ReS that embodiment 2 makes 2 Nanosheets dispersed in water to form 2mg·mL -1 For the dispersion solution, take 8 μL ReS 2 The dispersion liquid is drop-coated on the surface of the clean glassy carbon electrode obtained in step S1, and dried at room temperature to obtain ReS 2 / GCE modified electrode;

[0077] S3. Continue to drip-coat 6 μL of 10 μg / mL type III collagen antibody solution on the surface of the electrode prepared in step S2, dry it at room temperature, and use 0.01mol L -1 PBS b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com