Corrosion method for quickly, simply, conveniently and clearly displaying original austenite grain boundary of pipeline steel

A technology for clearly displaying the austenite grain boundary, which is applied in the field of simple and clear display of the corrosion of the original austenite grain boundary of pipeline steel, and can solve the problems of cumbersome operation, unsafe manual operation, and yellow skin, etc., to achieve The effect of simple operation, eliminating unsafe hidden dangers, and fast corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

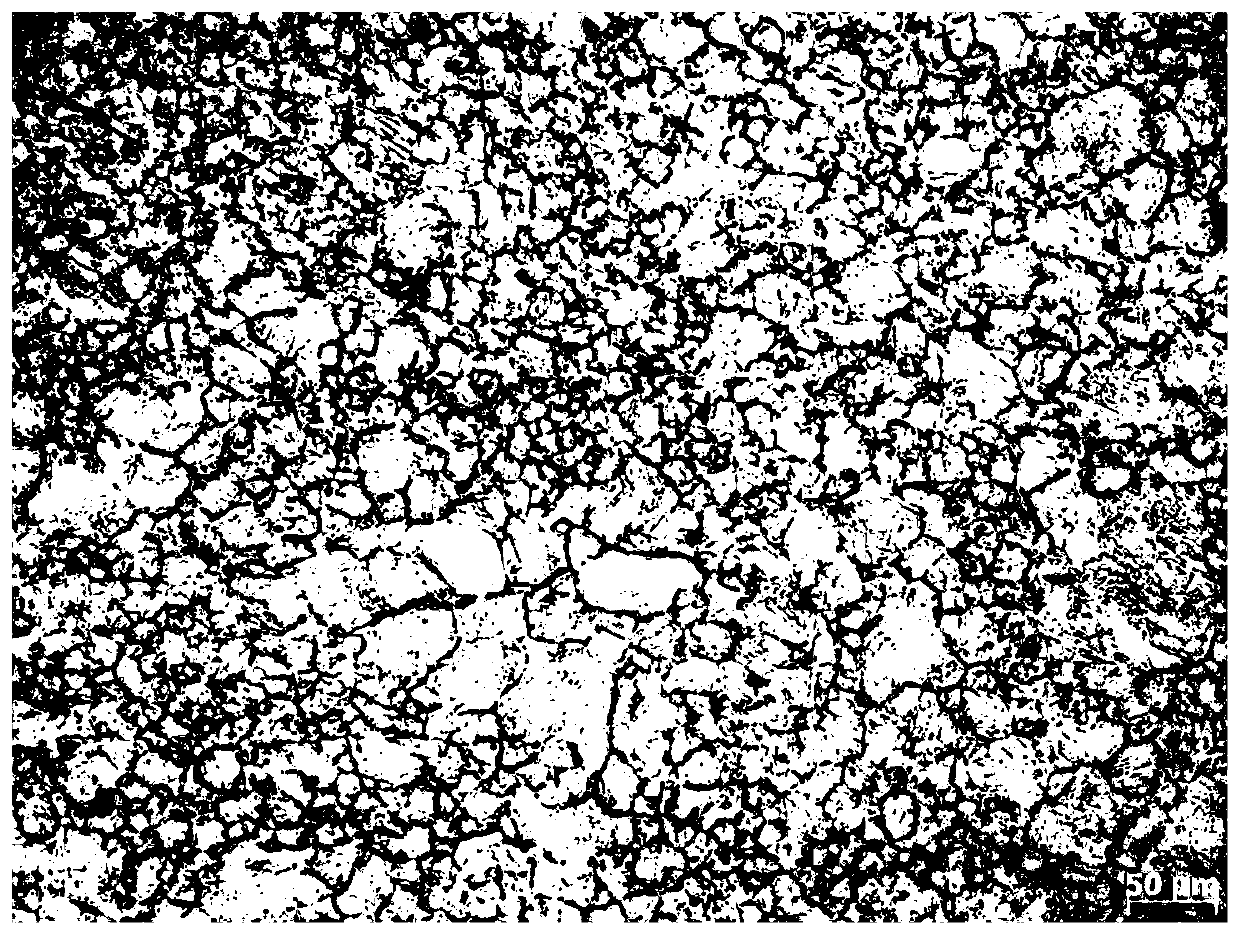

Embodiment 1

[0034] In this example, the chemical composition of pipeline steel is: C: 0.055%, Si: 0.23%, Mn: 1.58%, P: 0.011%, S: 0.001%, Cu: 0.009%, Ni: 0.36%, Cr: 0.20 %, Nb: 0.038%, Mo: 0.005%, V: 0.006%, Ti: 0.016%, Al: 0.015%, and the balance is Fe.

[0035] In this embodiment, the pipeline steel is smelted in a 25kg vacuum induction furnace and forged into a 80mm×70mm×70mm square billet.

[0036] (1) Metallographic sample preparation:

[0037] A sample with a size of 10m×12m×16mm was cut by wire cutting on the billet, and quenched after being kept at 1000°C, 1100°C and 1200°C for 36 minutes, and then the test surface of the sample to be tested was ground and polished, and then After cleaning with deionized water and alcohol in turn, dry it for later use;

[0038] (2) Corrosion solution preparation:

[0039] Weigh 3g of picric acid and pour it into a beaker filled with 50ml of distilled water, place the beaker in an ultrasonic cleaner set at 70°C and vibrate for 5 minutes to obtai...

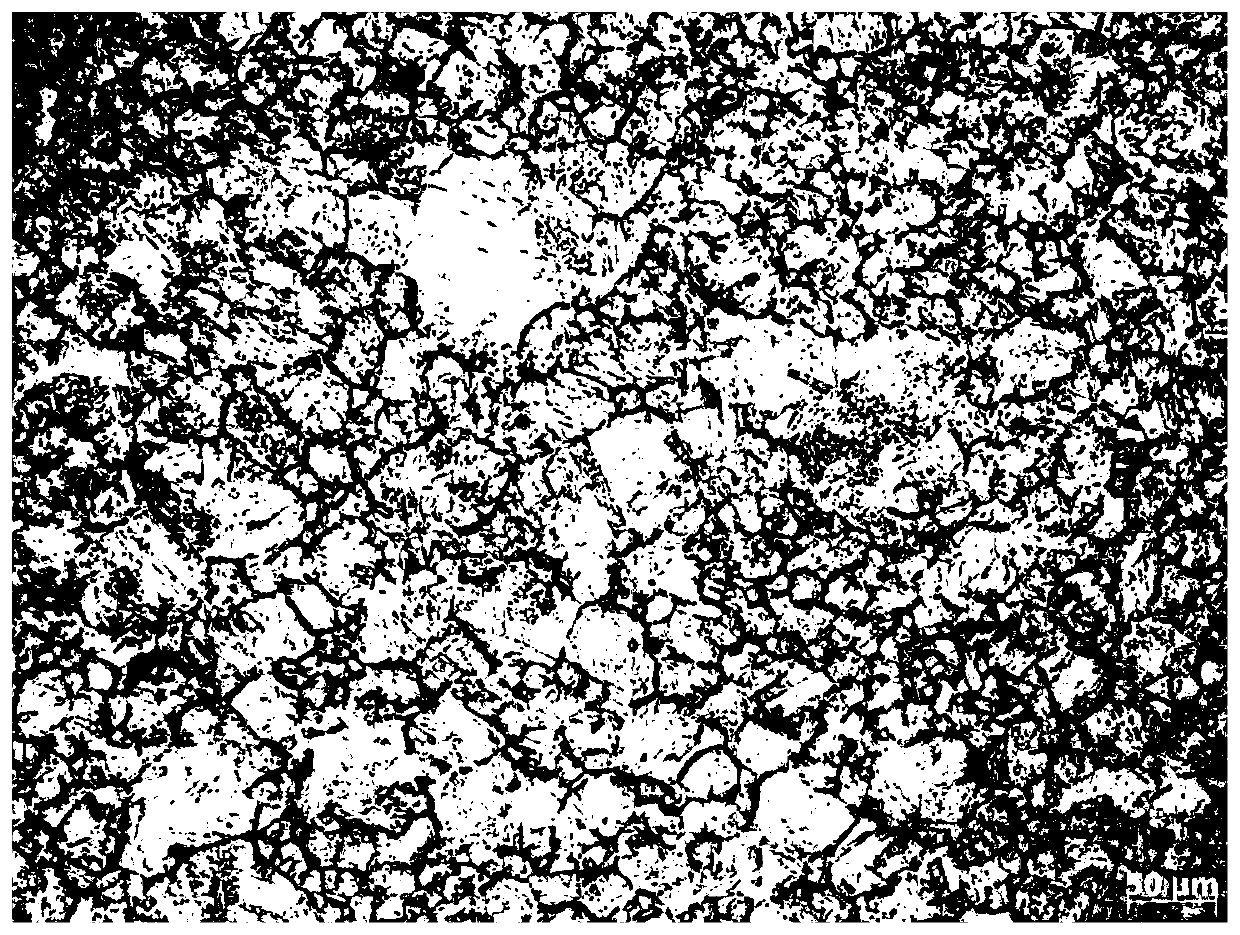

Embodiment 2

[0044]In this example, the chemical composition of pipeline steel is: C: 0.055%, Si: 0.23%, Mn: 1.58%, P: 0.011%, S: 0.001%, Cu: 0.009%, Ni: 0.36%, Cr: 0.20 %, Nb: 0.038%, Mo: 0.005%, V: 0.006%, Ti: 0.016%, Al: 0.012%, and the balance is Fe.

[0045] In this embodiment, the pipeline steel is smelted in a 25kg vacuum induction furnace and forged into a 80mm×70mm×70mm square billet.

[0046] (1) Metallographic sample preparation:

[0047] Cut a sample with a size of 10m×12m×16mm on the billet by wire cutting, heat it at 1150°C for 36min, 72min, and 108min, then quench it, then grind the testing surface of the sample to be tested and polish it, and then use After cleaning with deionized water and alcohol, dry it for later use;

[0048] (2) Corrosion solution preparation:

[0049] Weigh 3g of picric acid and pour it into a beaker filled with 50ml of distilled water, place the beaker in an ultrasonic cleaner set at 70°C and vibrate for 5 minutes to obtain a supersaturated picric...

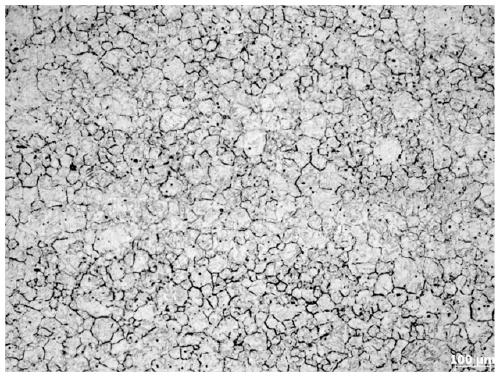

Embodiment 3

[0054] In this example, the chemical composition of pipeline steel is: C: 0.043%, Si: 0.19%, Mn: 1.66%, P: 0.009%, S: 0.001%, Cu: 0.15%, Ni: 0.17%, Cr: 0.23 %, Nb: 0.057%, Mo: 0.13%, V: 0.006%, Ti: 0.014%, Al: 0.023%, and the balance is Fe.

[0055] In this embodiment, the pipeline steel is smelted in a 25kg vacuum induction furnace and forged into a 80mm×70mm×70mm square billet.

[0056] (1) Metallographic sample preparation:

[0057] Cut a sample with a size of 10m×12m×16mm on the billet by wire cutting, heat it at 1150°C for 36min, 72min, and 108min, then quench it, then grind the testing surface of the sample to be tested and polish it, and then use After cleaning with deionized water and alcohol, dry it for later use;

[0058] (2) Corrosion solution preparation:

[0059] Weigh 3g of picric acid and pour it into a beaker filled with 50ml of distilled water, place the beaker in an ultrasonic cleaner set at 70°C and vibrate for 5 minutes to obtain a supersaturated picric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com