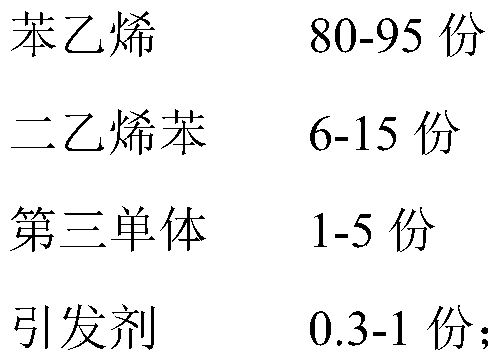

Preparation method of solvent-free gel type styrene cation exchange resin

A cation exchange and styrene-based technology, which is applied in the field of preparation of solvent-free gel-type styrene-based cation-exchange resins, can solve the problems of shortening the service life of the resin, reducing strength, and potential safety hazards, so as to improve the polarity of white balls and simplify process, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

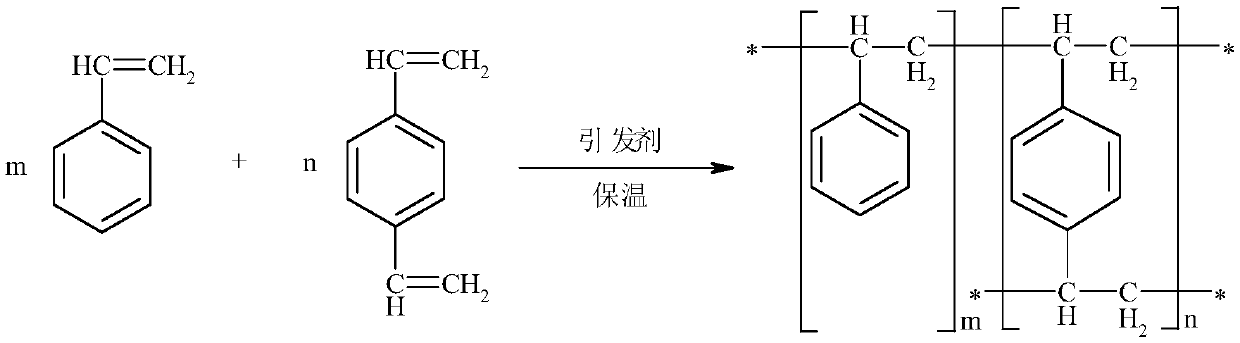

Method used

Image

Examples

Embodiment 1

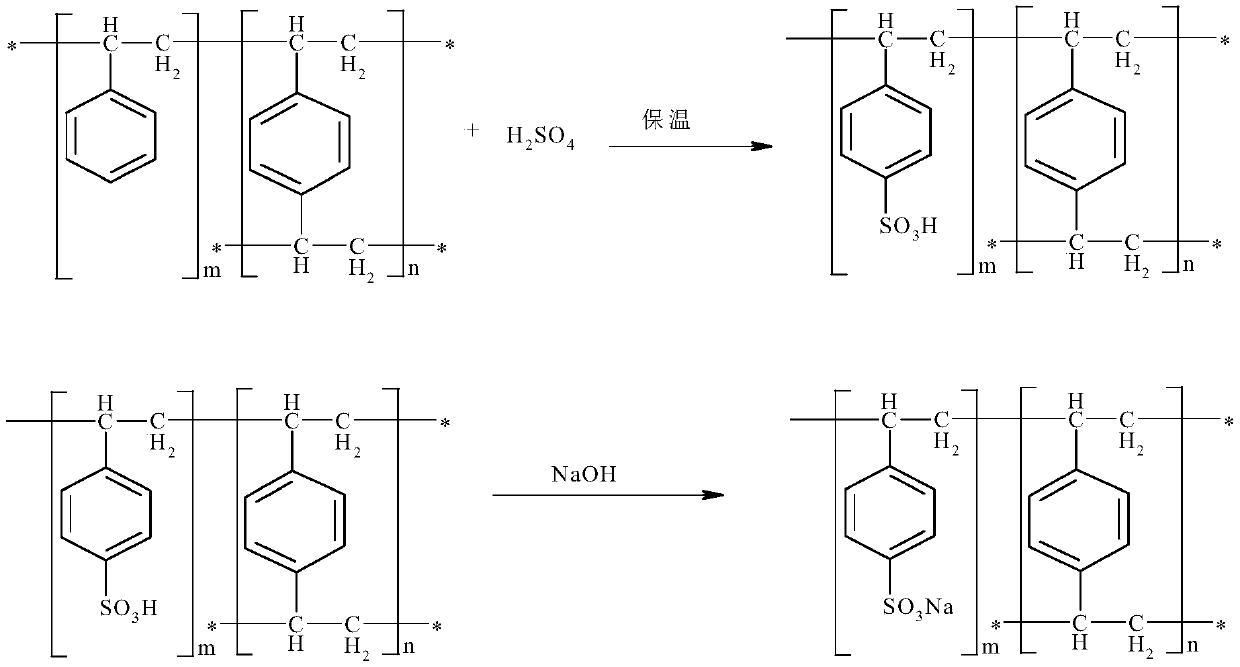

[0059] Weigh 11 parts of divinylbenzene with a mass fraction of 63%, 3 parts of methyl acrylate, 86 parts of styrene, and 1 part of BPO in a 500ml beaker, and stir evenly on a magnetic stirrer; add 225 parts of Water, add 0.4 parts of polyvinyl alcohol, stir at 40°C for 0.5 hours, add 12 parts of sodium chloride, heat up to 55°C, add the oil phase that has been stirred evenly in advance, adjust the stirring speed at 150 rpm, heat up to 75°C and keep warm 3h, then raise the temperature to 95°C and mature for 3h, cool down, and the white balls will be obtained; wash with hot water at about 80°C for 3 times, rinse with tap water, filter out the water, and dry at 70°C. After drying, sieve white balls with a particle size of 0.315-0.710mm.

[0060] Weigh 100g of 0.315-0.710mm white balls, add 600g of 93.5% sulfuric acid into a 1000ml three-neck flask, heat up to 80°C for 2 hours, heat up to 115°C for 6 hours for sulfonation reaction, cool down to about 40°C after the reaction, add ...

Embodiment 2

[0062] In a 500ml beaker, 12 parts of divinylbenzene with a mass fraction of 63%, 4 parts of acrylic acid, 84 parts of styrene, and 1 part of BPO are weighed in a 500ml beaker, and stirred evenly on a magnetic stirrer; 250 parts of water are added in a 1000 ml three-necked flask, Add 0.4 parts of polyvinyl alcohol, stir at 40°C for 0.5 hours, add 15 parts of sodium chloride, heat up to 55°C, add the oil phase that has been stirred evenly in advance, adjust the stirring speed at 150 rpm, raise the temperature to 77°C and keep for 3 hours, Then heat up to 95°C and mature for 3 hours, then cool down to produce white balls; wash with hot water at about 80°C for 3 times, rinse with tap water, filter out the water, and dry at 70°C. After drying, sieve white balls with a particle size of 0.315-0.710mm.

[0063] Weigh 100g of 0.315-0.710mm white balls, add 650g of 95% sulfuric acid into a 1000ml three-necked flask, raise the temperature to 80°C and keep it for 2h, then raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com