Production process of guide board

A production process and road sign technology, applied in the field of traffic engineering, can solve the problems of easy adhesion of impurity debris, blocking the spraying position, uneven spraying, etc., to achieve the effect of bright appearance, reduction of replacement frequency and loss, and reasonable and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] The invention discloses a road sign production process, which comprises the following steps: S01: cutting, selecting an aluminum alloy plate, cutting according to the designed size to obtain a bottom plate; S02: cleaning, cleaning the bottom plate; S03: surface treatment, The bottom plate treated by S02 is immersed in alkaline detergent for cleaning, then washed with clean water, and dried with warm air or infrared rays; S04: Paste reflective film, and paste the reflective film on the surface of the bottom plate treated by S03; S05 : lettering, computer layout pattern and text, and use computer engraving machine to directly engrave text and patterns on the reflective film; S06: pressing, use rubber plate to scrape and press the text and patterns on the reflective film.

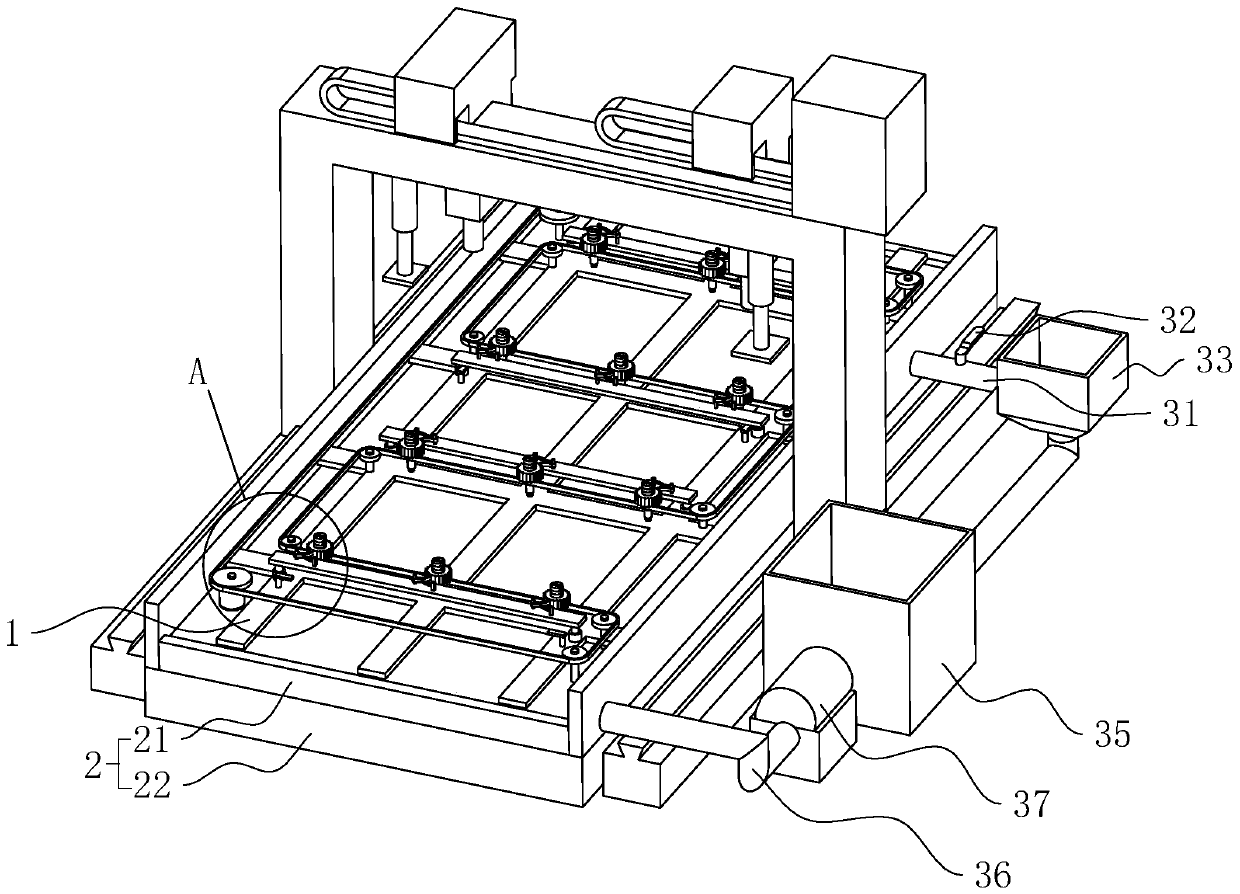

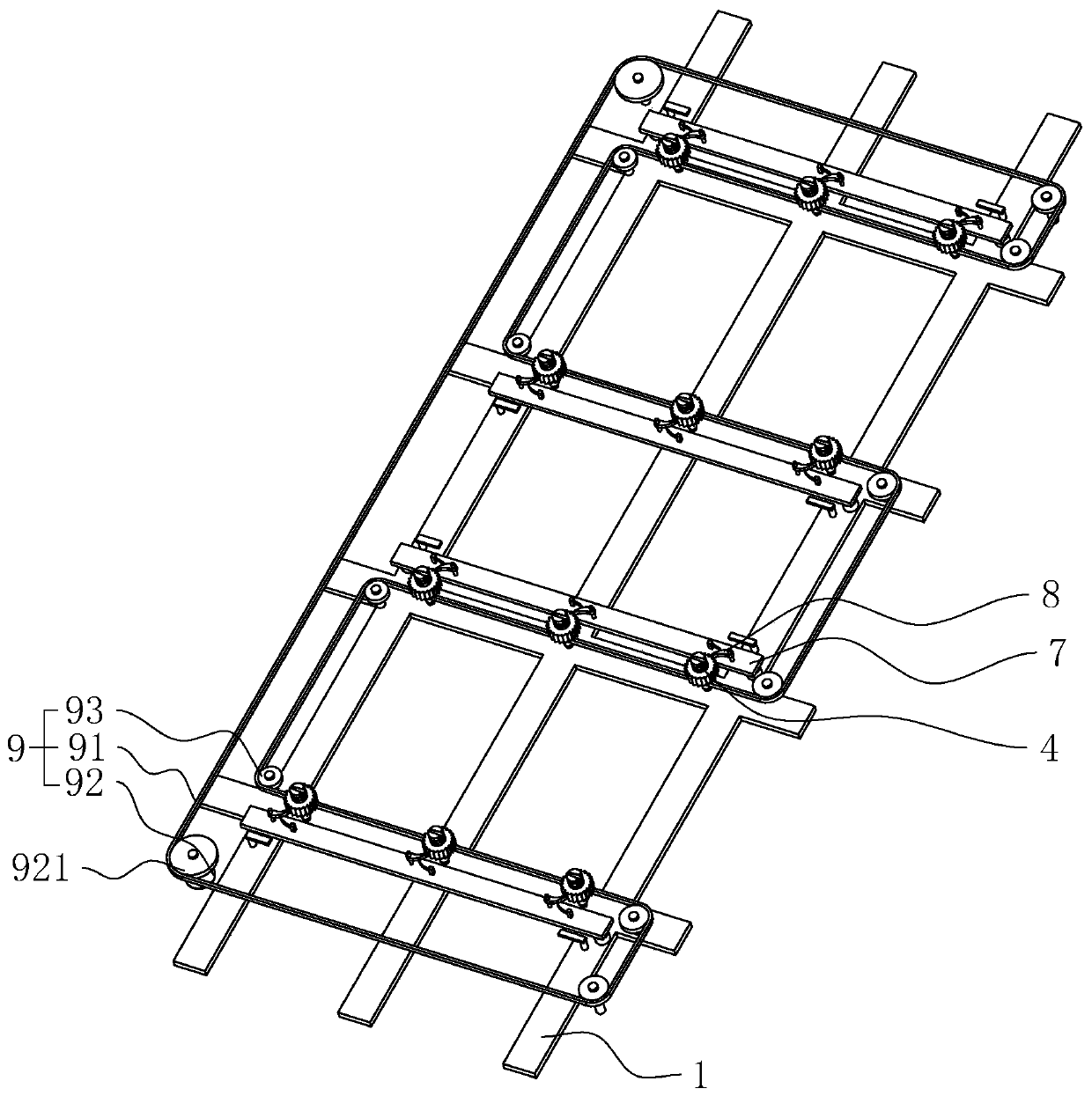

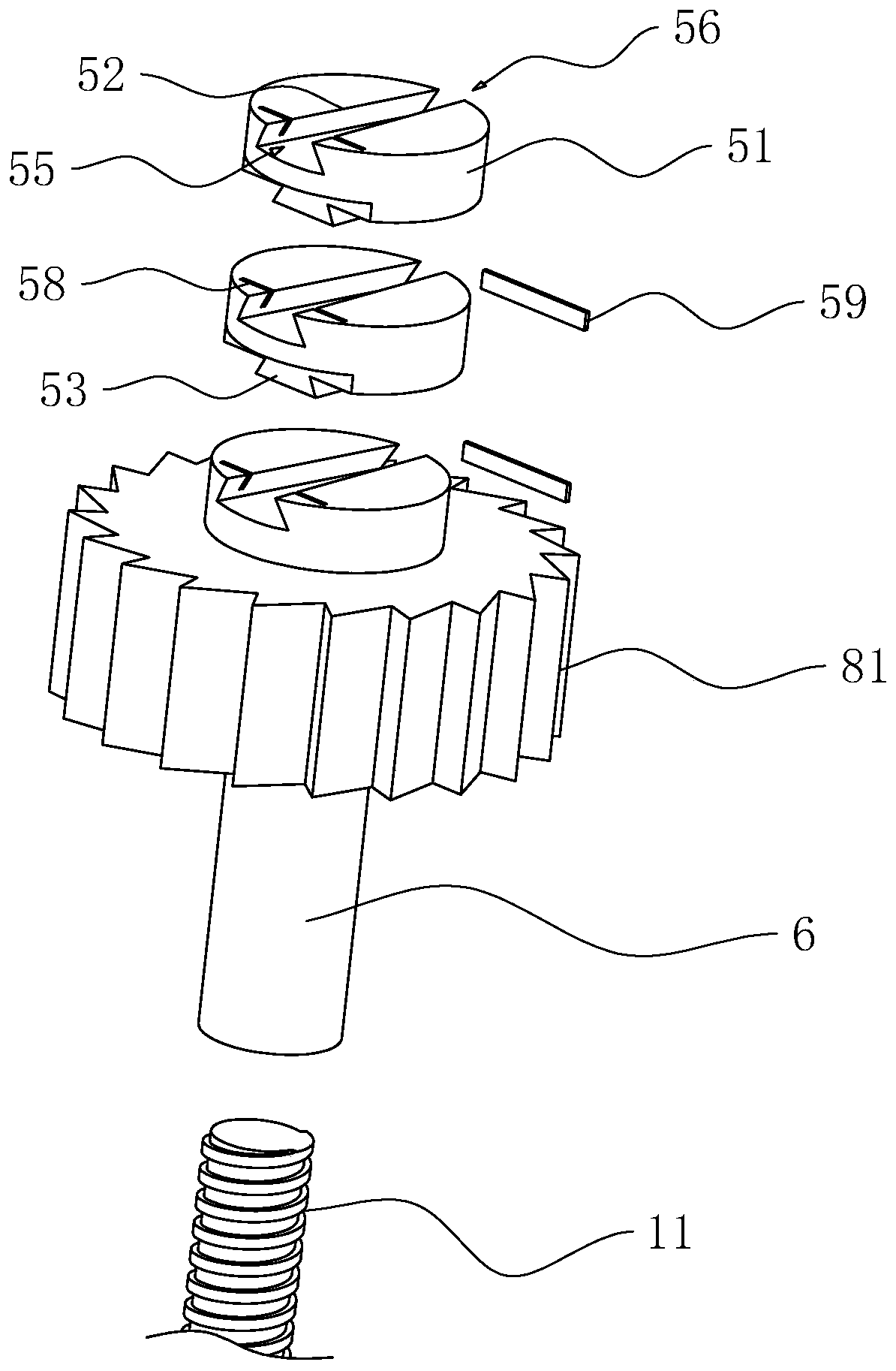

[0040] Among them, the cutting in S01 is cutting through the working platform of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com