A Method for Removing Pore Defects in Metal Additive Manufacturing Components Based on Online Monitoring

A metal additive and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of inability to impact hardening of workpieces, stay of internal pore defects, waste of time and energy, etc., to simplify the laser shock strengthening process, promote recrystallization, Avoid ablative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

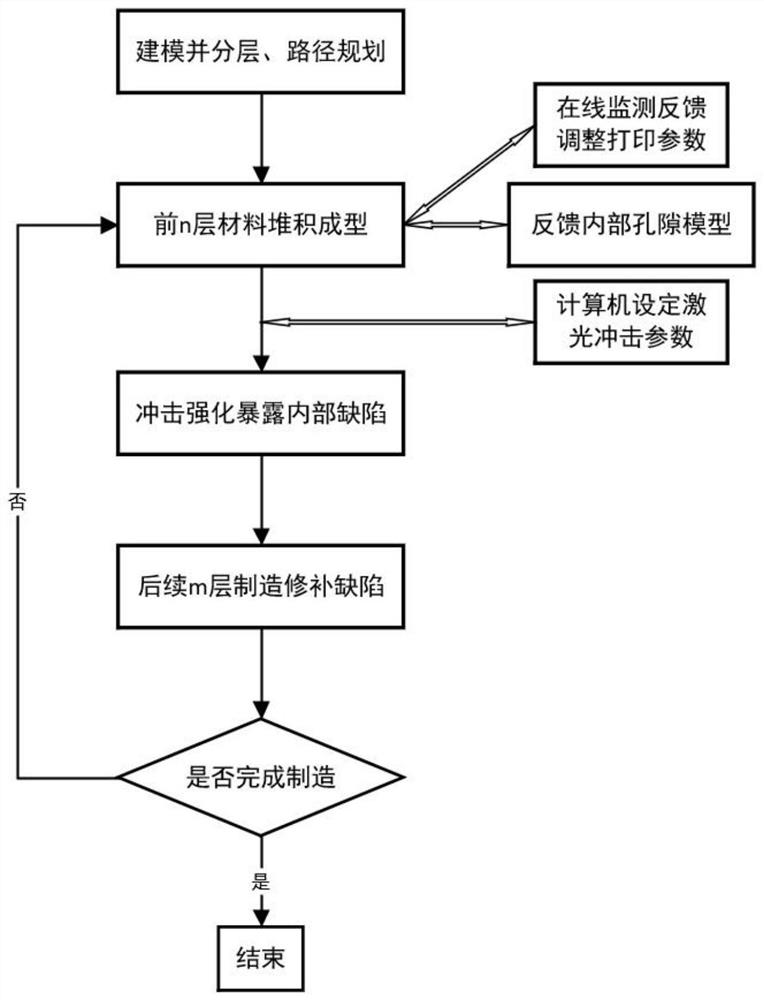

[0030] Such as figure 1 As shown, a method for removing pore defects in metal additive manufacturing components based on online monitoring includes the following steps:

[0031] 1) Carry out three-dimensional modeling with computer CAD software to obtain a sample model with a size of 100mm*60mm*60mm, and use the DED metal additive manufacturing system slice layer software to layer the model and plan the path;

[0032] 2) The DED metal additive manufacturing system carries out the additive manufacturing process. The wire material AA5183 aluminum alloy is selected as the raw material to deposit the first layer of material. Since the single layer thickness of the WAAM process deposition material is large, the first 1 layer is selected in this embodiment. layer;

[0033] In the WAAM process deposition process, the wire feeding speed is 15....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com