Jointing structure of composite floor

A technology for superimposing floor slabs and structures, applied in the direction of floors, building structures, building components, etc., can solve problems such as cracks at the joints and changes in the mechanical performance of the slabs, so as to save the formwork process and ensure the mechanical performance , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

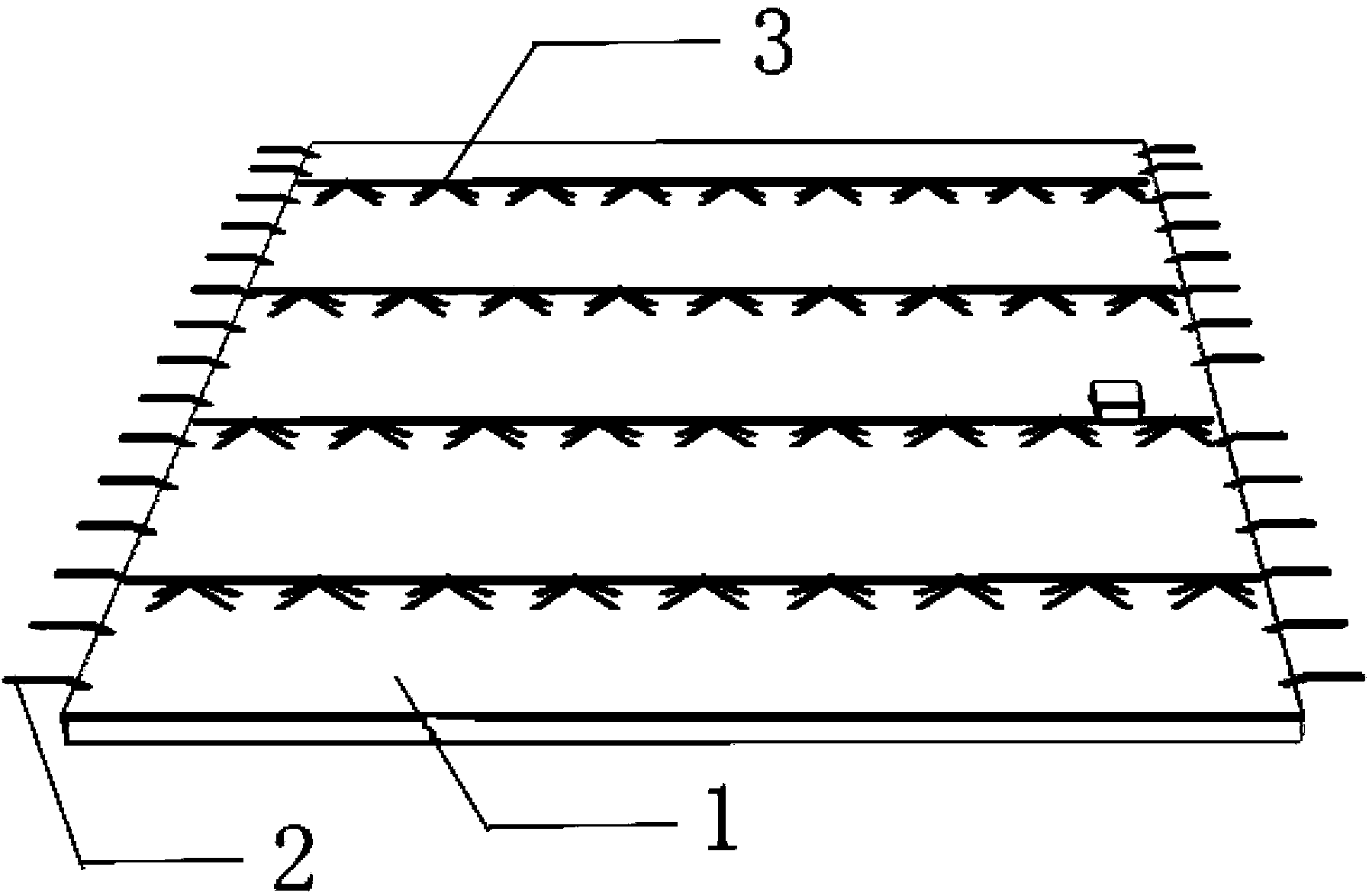

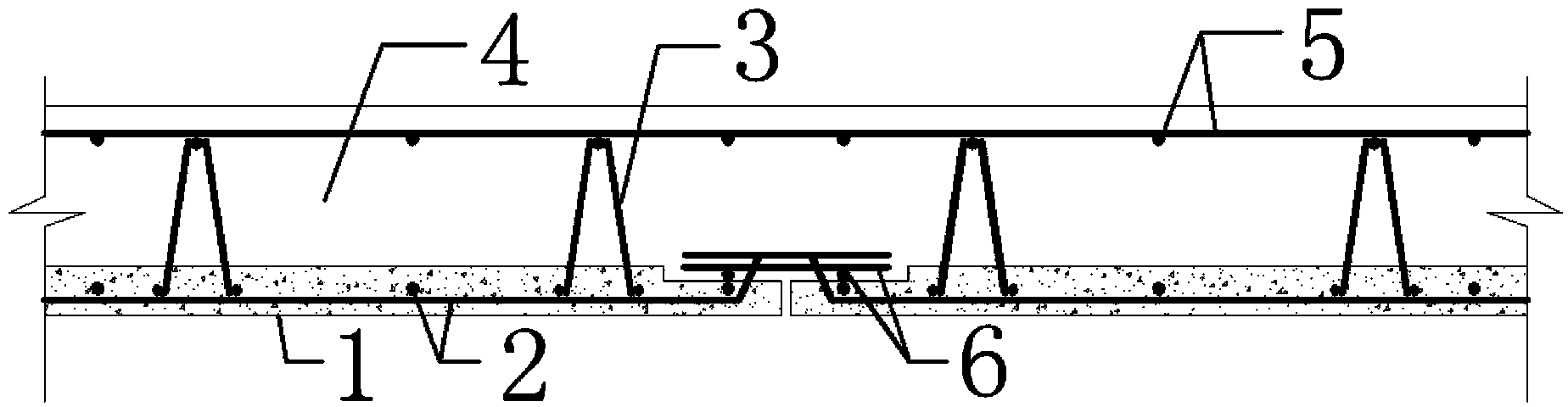

[0024] Embodiment 1: as figure 2 As shown, the laminated floor slab includes a prefabricated concrete slab 1 , a lower reinforcement mesh 2 , a truss reinforcement 3 , an additional reinforcement 6 , an upper reinforcement mesh 5 and cast-in-place concrete 4 . The truss reinforcement 3 is bound to the lower reinforcement mesh 2 and poured into the prefabricated concrete slab 1 . When splicing, add additional reinforcement 6 to the lower layer of the joint, the thickness of the two prefabricated concrete slabs 1 is reduced within the range of the additional reinforcement 6 at the joint, and the lower reinforcement near the joint can be bent at a place where there is enough thickness of the protective layer. Go over the seams. 5 frames of the upper layer of reinforcement mesh stand on the top surface of the truss reinforcement 3, and the upper layer of additional reinforcement 6 can be added to the joints, and finally the concrete is poured. It should be noted that the inner ...

Embodiment 2

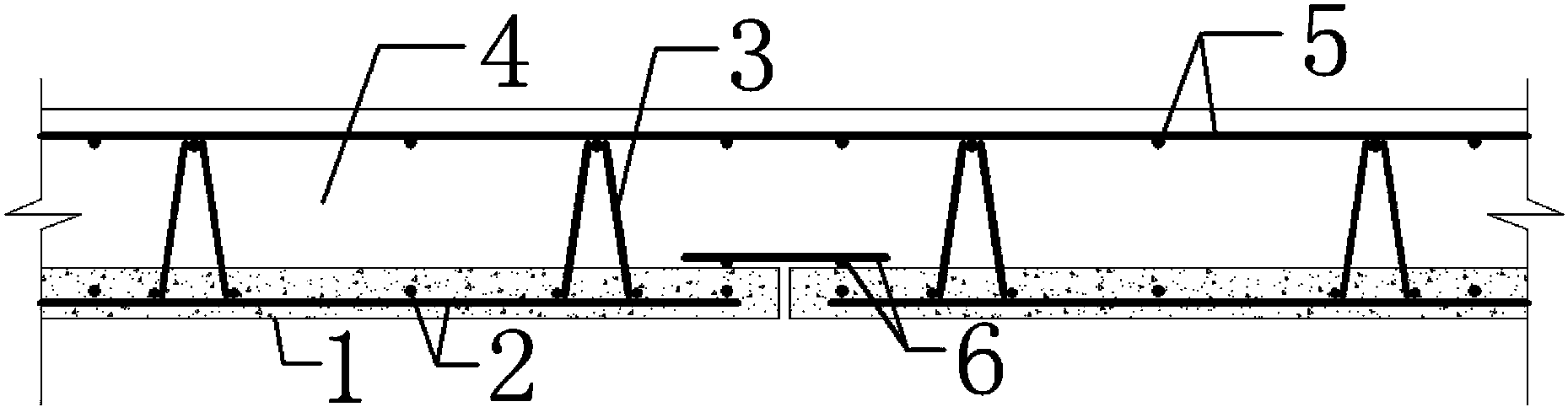

[0025] Embodiment 2: as image 3 As shown, the two precast concrete slabs 1 did not change the thickness of the precast concrete slab 1 at the joint, nor bent the lower steel mesh 2, but cut off the precast concrete slab 1, added additional steel bars 6 at the joint, and the rest Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com