Method for adding solder resist bridge between narrow IC pads on thick copper PCB

A technology for PCB boards and solder bridges, applied in the field of printed circuit boards, can solve problems such as reducing production costs, and achieve the effects of reducing solder short circuits and improving yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

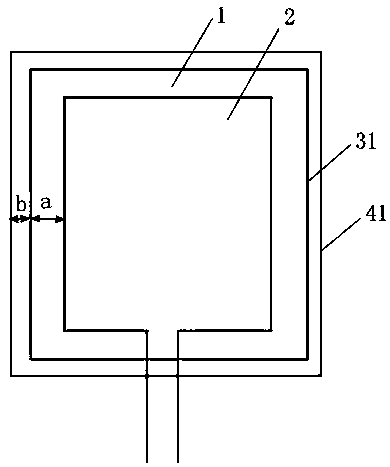

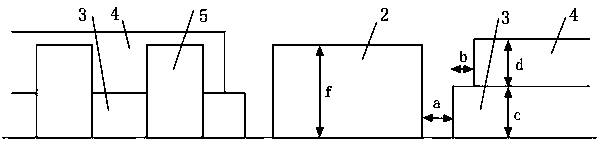

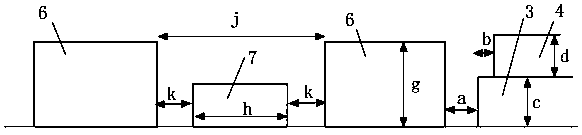

[0021] A method of adding solder-rejection bridges between narrow and small IC pads on a thick copper PCB:

[0022] Step 1. Create the outer layer circuit of single, double, or multilayer printed circuit board (PCB board), the thickness of the outer layer circuit is 25 microns to 125 microns, including copper lines and copper pads, etc., and the PCB board The distance between adjacent IC pads is greater than or equal to 150 microns;

[0023] Step 2: Use screen printing to print the first layer of ink on the surface of the PCB and pre-bake it; the thickness of the first layer of ink is from 25 microns to 65 microns (measured from the substrate);

[0024] Step 3: Use the photosensitive film imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com