Lithium battery negative electrode material and preparation method

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of lithium dendrites, restricting development and application, dead lithium, etc., to achieve increased surface area, less consumption of lithium ions, The effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

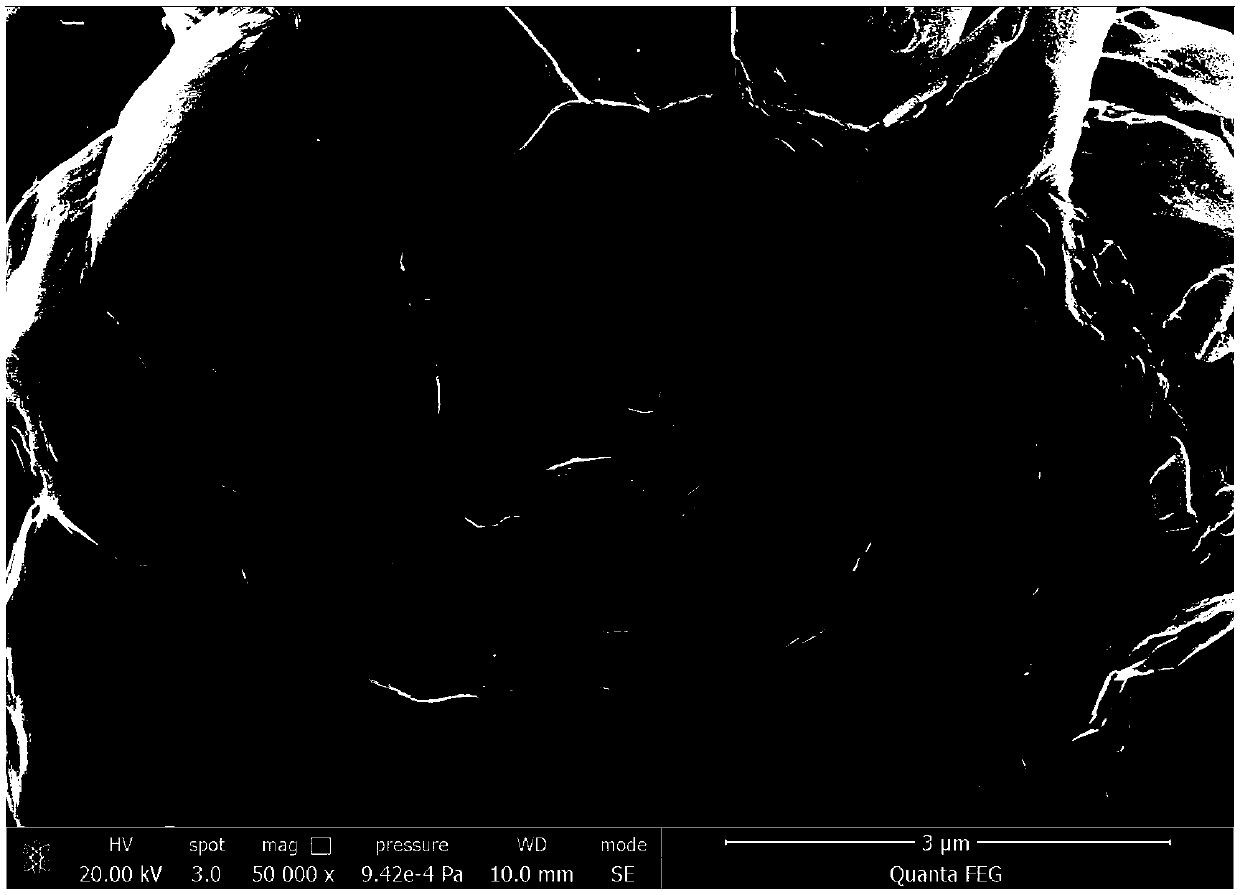

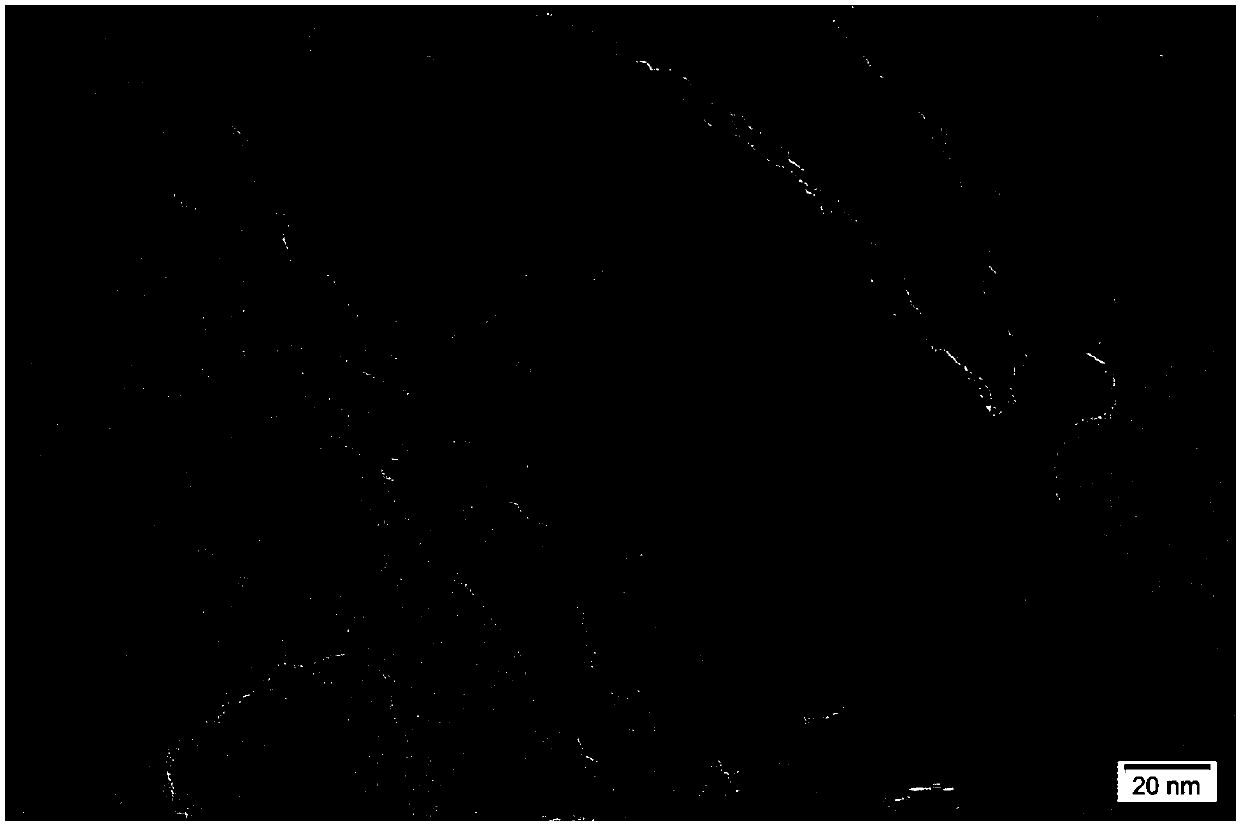

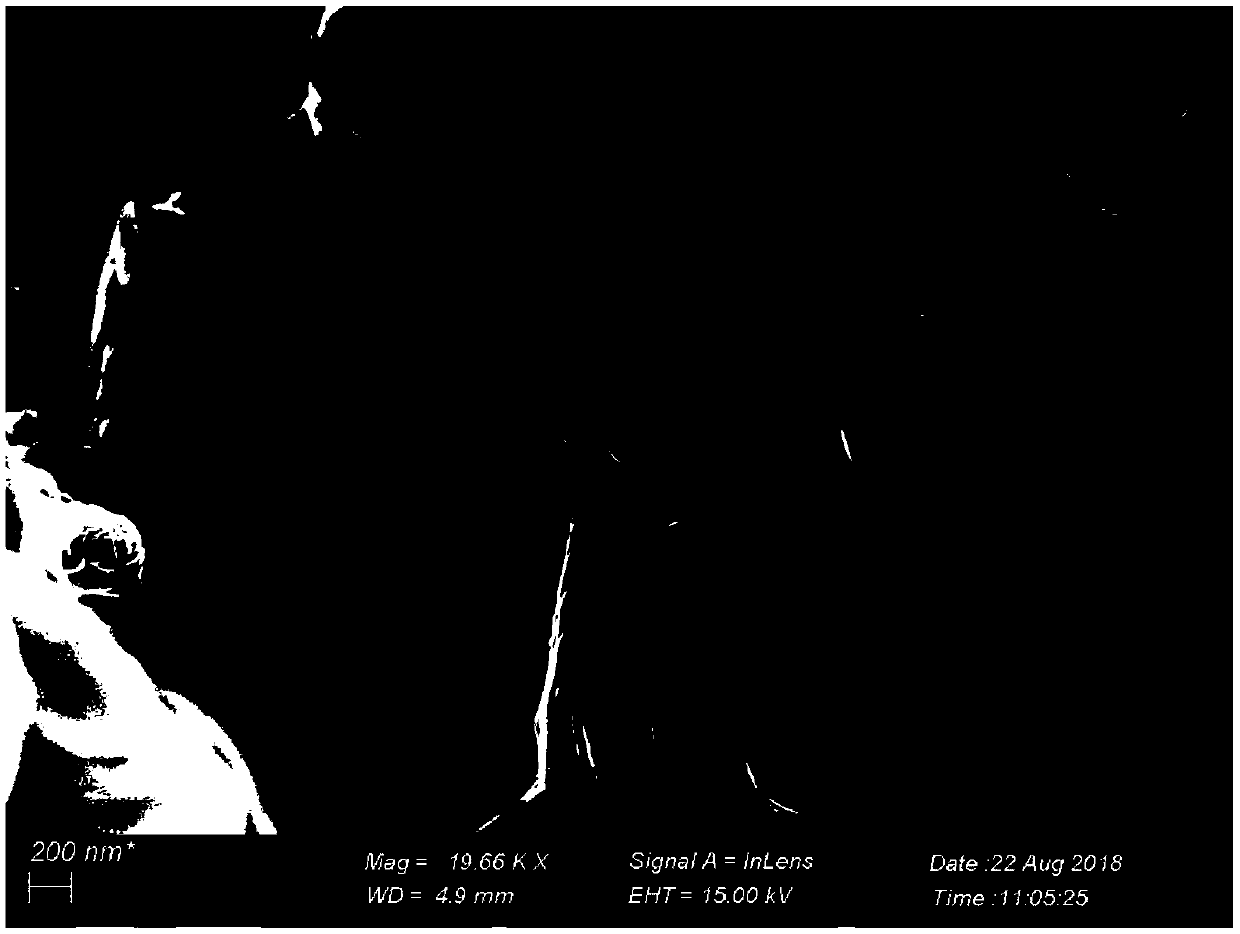

Image

Examples

Embodiment 1

[0051] A lithium battery negative electrode material, the preparation method following steps:

[0052] Physical treatment: take coal-based coke powder and dry until the water content is less than 1%, crush to 6-18μm, after grading, shaping and spheroidizing,

[0053] Chemical treatment: Add the spheroidized coal-based coke powder to a mixed acid composed of 15% hydrochloric acid and 19% hydrofluoric acid by mass percentage, filter, rinse, and filter again, then dry.

[0054] Graphitization: Under the protection of high-purity nitrogen, the coal-based coke powder after chemical treatment and drying is heated by the following multi-stage heating method to obtain the negative electrode material;

[0055] The carbonized product goes through at least two heating stages from 0-10°C to reach 2900-3000°C. Each heating stage includes two successive sub-heating stages. stage heating rate.

[0056] Further scheme, the heating up process of the multi-stage heating up of described graphi...

Embodiment 2

[0069] This embodiment is a specific implementation of Embodiment 1, the preparation method of lithium battery negative electrode material, comprising the following steps:

[0070] Physical treatment: take coal-based coke powder and dry until the water content is less than 1%, crush to 6-18μm, after grading, shaping and spheroidizing,

[0071] Chemical treatment: Add the spheroidized coal-based coke powder to a mixed acid composed of 15% hydrochloric acid and 19% hydrofluoric acid by mass percentage, filter, rinse, and filter again, then dry.

[0072] Graphitization: Under the protection of high-purity nitrogen, the coal-based coke powder after chemical treatment and drying is heated by the following multi-stage heating method:

[0073] The first heating stage: the product after chemical treatment is raised from 0-10°C to 780-800°C at the first heating rate V1, and then to 1150-1200°C at the second heating rate V2, V1>V2,

[0074] The second heating stage: from 1150-1200°C to...

Embodiment 3

[0085] The difference between the present embodiment and the second embodiment is that the multi-stage heating method adopted in the graphitization in the present embodiment is as follows:

[0086] The first heating stage: the carbonized product is raised from 0-10°C to 400-450°C at the first heating rate V1, and then to 900-920°C at the second heating rate V2, V1>V2,

[0087] The second heating stage: from 900-920°C to 1300-1350°C at the third heating rate V3, and then to 1700-1800°C at the fourth heating rate V4, V3>V4,

[0088] The third heating stage: from 1700-1800°C to 2200-2300°C at the fifth heating rate V5, and then to 2900-3000°C at the sixth heating rate V6, V5>V6;

[0089] Finally, the negative electrode material is obtained after 0.5-1.0 hours of heat preservation.

[0090] The first heating rate V1 is 60-62°C / hour, the second heating rate V2 is 40-41°C / hour, the third heating rate V3 is 85-87°C / hour, and the fourth heating rate V4 is 20-22°C / hour hour, the fift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com